Overload protection diverter used for power transmission of harvester

A technology of power transmission and overload protection, applied in harvesters, transmission devices, applications, etc., can solve problems such as increased maintenance costs and damage to commutator transmission parts, and achieves reduced maintenance costs, large force contact area, and transmission. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

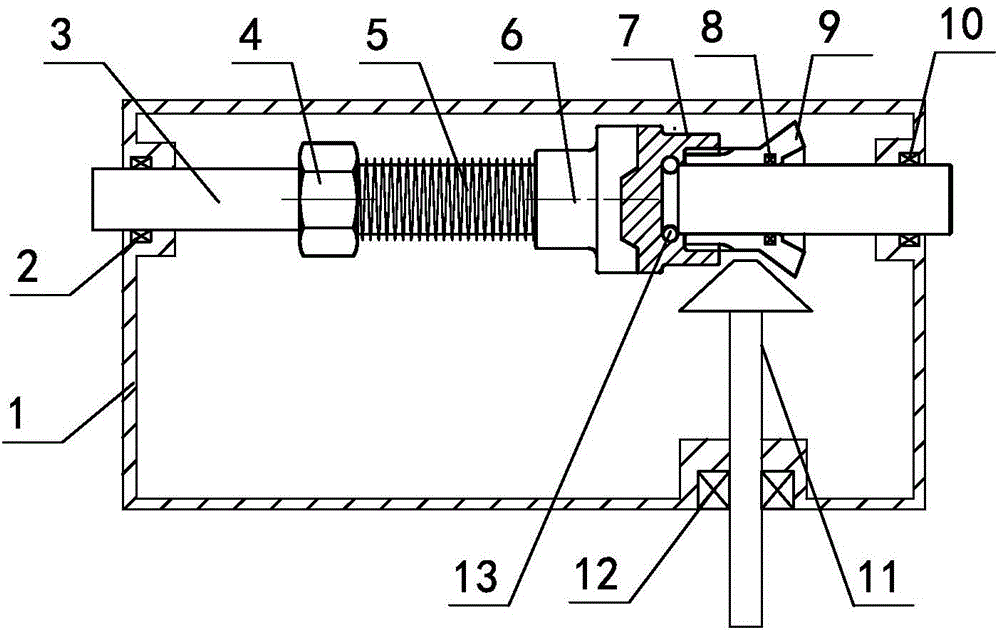

[0017] Such as figure 1 As shown, the overload protection commutator used for the power transmission of the harvester includes a box body 1, and a shaft 3 is installed transversely in the box body 1, and the left end of the shaft 3 is installed on the left wall of the box body 1 through the first bearing 2, The right end of the shaft 3 is installed on the right wall of the box body 1 through the second bearing 10, and the bevel teeth 9 are installed on the shaft 3 through the third bearing 8, and the corresponding bevel teeth 9 are installed longitudinally in the box body 1. The meshing bevel gear shaft 11, the bevel gear end of the bevel gear shaft 11 meshes with the bevel gear 9, the shaft part of the bevel gear shaft 11 is installed on the box body 1 through the fourth bearing 12, and the shaft 3 on the left side of the bevel gear 9 There is a nut 4 threaded on the top, and the shaft 3 on the right side of the nut 4 is equipped with a clutch-6 for the power transmission of ...

Embodiment 2

[0021] A change is made on the basis of the first embodiment, and the clutch one 6 and the shaft 3 are fitted with a flat key; the natural length of the spring 5 is changed to 200 mm. Others are the same as embodiment one.

Embodiment 3

[0023] On the basis of the first embodiment, the natural length of the spring 5 is changed to 300mm. Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Natural length | aaaaa | aaaaa |

| Natural length | aaaaa | aaaaa |

| Natural length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com