Improved laminar flow hood mechanism

A technology of laminar flow hood and cover, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

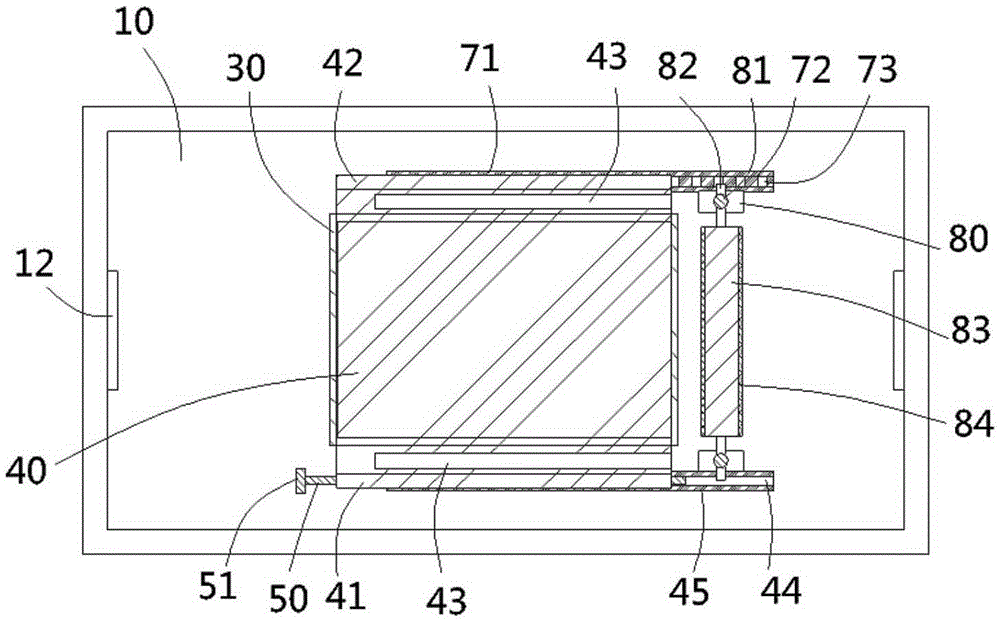

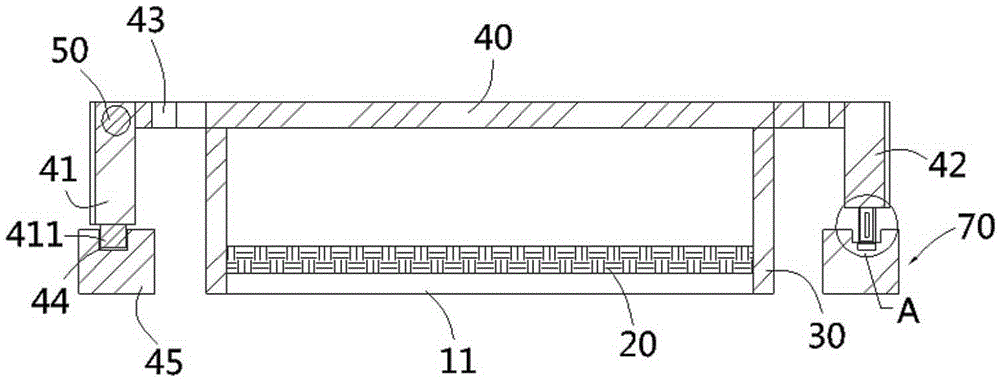

[0023] See figure 2 , The improved laminar flow hood mechanism of the present invention includes a hood 10 on which an air inlet 11 is formed, and a filter screen 20 covers the air inlet 11 and is fixed to the hood 10, A vertical rectangular ventilation duct 30 is fixed at the air inlet 11;

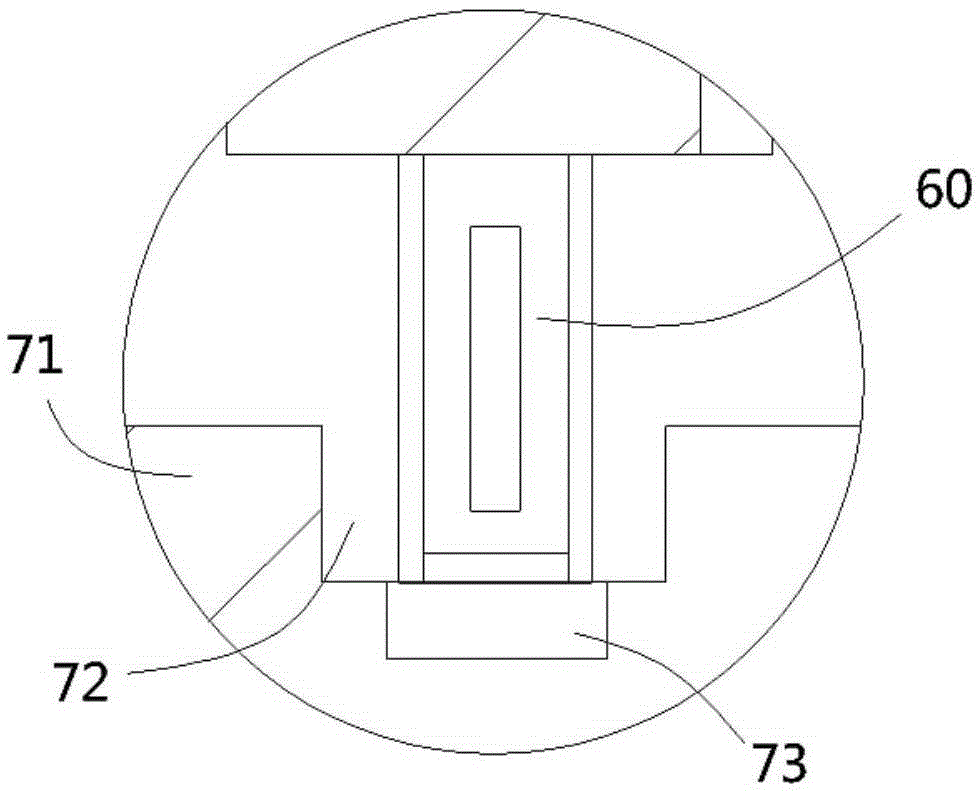

[0024] See Figure 1 to Figure 3 , The rectangular ventilation duct 30 is pressed against a rectangular cover plate 40, the two sides of the cover plate in the width direction extend out of the two sides of the rectangular ventilation duct 30, and the two sides of the cover plate 40 in the width direction are formed vertically downward The main moving part 41 and the auxiliary moving part 42 of the main moving part 41 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com