Rapid extraction method of radix aconite lateralis preparata total alkaloids

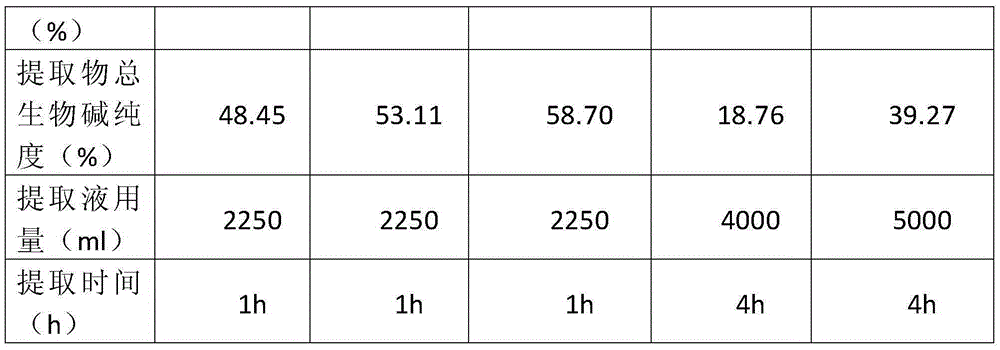

A technology of total alkaloids and extraction method, which is applied in the field of rapid extraction of total alkaloids of aconite, can solve the problems of long extraction time, large amount of extraction liquid, and large amount of high-concentration organic solvents, etc., and achieves short extraction time and high extraction rate , The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Wash fresh aconite;

[0031] 2. Beat the fresh aconite with 4 times of 0.2% hydrochloric acid and separate the pulp and residue, and repeat the pulping once for the coarse residue to obtain residue and slurry;

[0032] 3. Separating the obtained slurry from water to solid-liquid to obtain starch and clear liquid;

[0033] 4. Wash the starch and slag with 0.5 times the weight of fresh aconite water twice and dehydrate to obtain the cleaning solution; dry the starch;

[0034] 5. After merging the part of the clear liquid obtained in 3 (30% of the clear liquid obtained in step 3) and the cleaning liquid obtained in step 4 to supplement the acid concentration (hydrochloric acid solution with a mass percentage concentration of 0.2%), return to 2 and reuse it as the extract ;

[0035] 6. Remove the protein from the remaining clear liquid, and adjust the pH to 8 by adding alkali;

[0036] 7. Put the pH-adjusted supernatant on a D101 macroporous resin column, elute with 5...

Embodiment 2

[0038] 1. Wash fresh aconite;

[0039] 2. Beat the fresh aconite with 8 times of 0.6% citric acid and separate the pulp and residue, and repeat the pulping once for the coarse residue to obtain residue and slurry;

[0040] 3. Separating the obtained slurry from water to solid-liquid to obtain starch and clear liquid;

[0041] 4. Wash the starch and slag with fresh water of 1 times the weight of fresh aconite and dehydrate to obtain a cleaning solution; dry the starch;

[0042] 5. Combine the part of the clear liquid obtained in 3 (60% of the clear liquid obtained in step 3) and the cleaning liquid obtained in step 4 to supplement the acid concentration (citric acid solution with a concentration of 0.6% by mass) and return to step 2 as an extract reuse;

[0043] 6. Remove the protein from the remaining clear liquid, and adjust the pH to 8 by adding alkali;

[0044] 7. Put the pH-adjusted supernatant on a D101 macroporous resin column, elute with 5BV80% ethanol after removing...

Embodiment 3

[0046] 1. Wash fresh aconite;

[0047] 2. Beat the fresh aconite with 1 times 0.5% acetic acid and separate the pulp and slag, and repeat the beating once for the coarse slag to obtain slag and pulp water;

[0048] 3. Separating the obtained slurry from water to solid-liquid to obtain starch and clear liquid;

[0049] 4. Wash the starch and slag twice with fresh water of 1 times the weight of fresh aconite and dehydrate to obtain the cleaning solution; dry the starch;

[0050] 5. Combine the part of the clear liquid obtained in 3 and the cleaning liquid obtained in step 4 to supplement the acid concentration (0.5% acetic acid solution in mass percent concentration) and then return to 2 for reuse as the extract;

[0051] 6. Deproteinize the remaining supernatant, add alkali to adjust the pH to 9;

[0052] 7. Put the pH-adjusted supernatant on a D101 macroporous resin column, elute with 5BV80% ethanol after removing impurities with distilled water, and obtain the total alkaloi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com