Electric fan and electric vacuum cleaner

A blower, electric technology, applied in the manufacture of motor generators, electric components, machines/engines, etc., can solve the problems of difficult winding orderly arrangement, long winding length, hindering the efficiency improvement and light weight of electric blowers, etc., to achieve easy orderly arrangement. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0076] structure

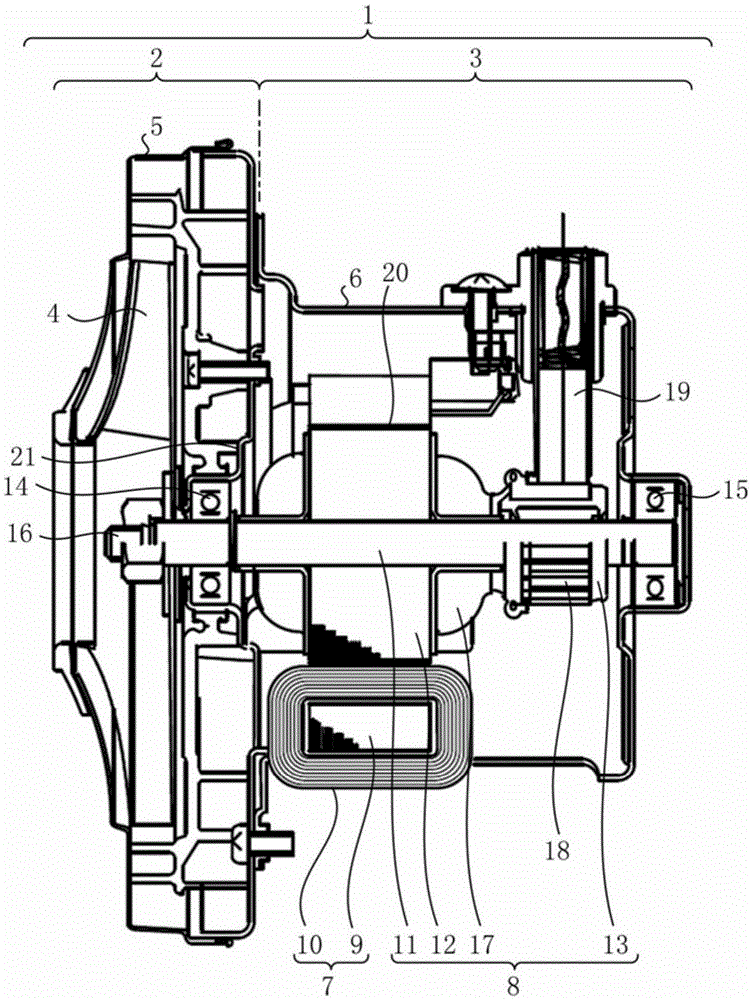

[0077] figure 1It is a vertical cross-sectional view showing a schematic structure of the inside of the electric blower according to the present embodiment. The electric blower 1 is roughly divided into two units, a blower unit 2 that generates suction force, and a commutator motor 3 that drives the blower unit 2 . Electric blower 1 can be applied to, for example, an electric vacuum cleaner.

[0078] The air blower 2 includes: a fan 4 having a plurality of blades; and a fan guide 5 that covers the fan 4 and guides the air that circulates with the rotation of the fan 4 to the inside of the commutator motor 3 . The circulating air cools the commutator motor 3 that generates heat during operation, and is discharged from an opening (not shown) provided in the frame 6 .

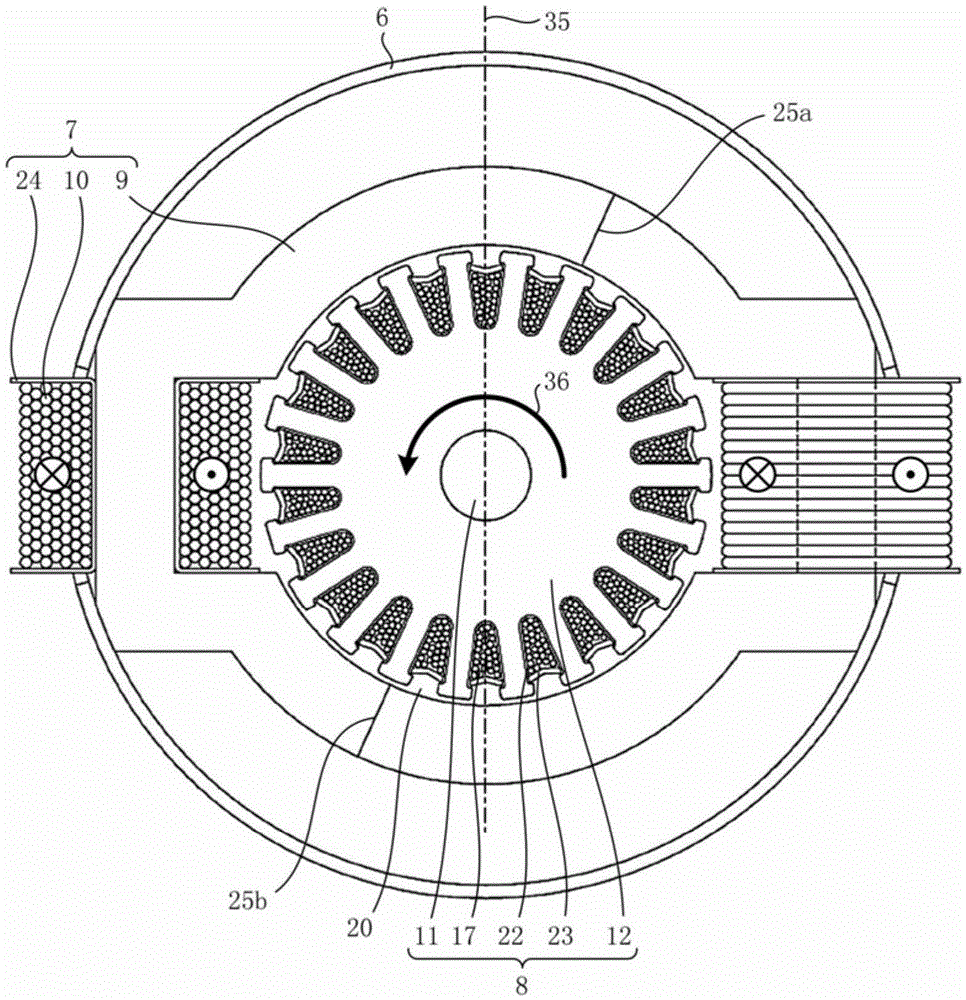

[0079] Commutator motor 3 includes: stator 7, which is fixed on the inner side of cup (tube)-shaped frame 6, and plays the role of excitation; The way is supported, play the role of the arma...

Embodiment approach 2

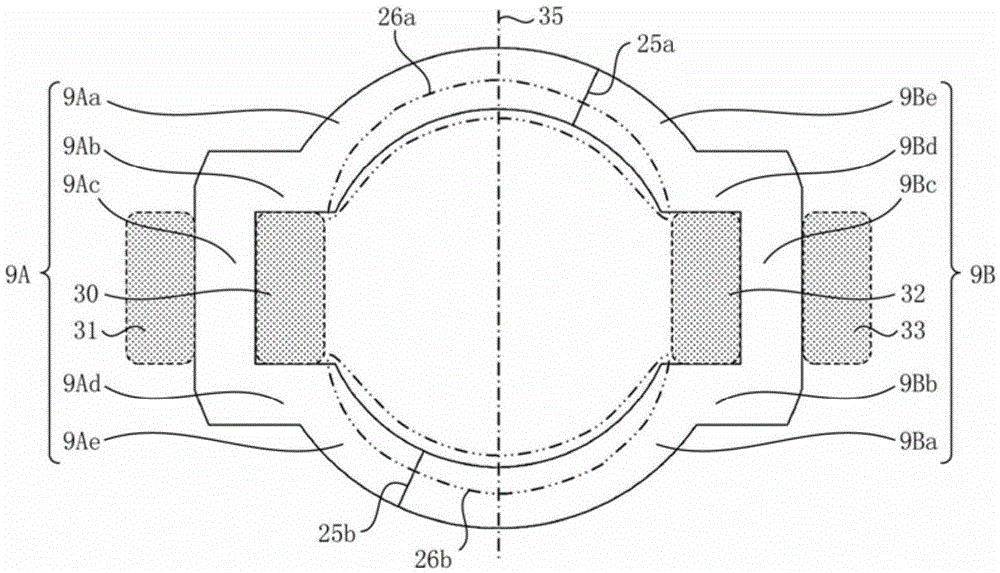

[0097] In this embodiment, regarding the shapes of the two C-shaped portions 9A and 9B constituting the stator core 9 , portions different from those in Embodiment 1 will be described.

[0098] structure

[0099] In the electric blower 1, if the radial widths (magnetic path widths) of the left end portion 9Aa, the right end portion 9Be, the right end portion 9Ae, and the left end portion 9Ba of the two C-shaped portions 9A, 9B facing the rotor 8 are closer to the iron The smaller the core division positions 25a and 25b, the better. Figure 6 and Figure 7 An example application is shown in . Figure 6 and Figure 7 and image 3 Similarly, it is a figure which looked at the stator core 9 from an axial direction, and is a figure which shows the shape of the stator core 9 of this embodiment. exist Figure 6 Among them, the surfaces where the C-shaped portion 9A and the C-shaped portion 9B abut are provided with a small width at the core division positions 25a and 25b. In a...

Embodiment approach 3

[0107] In the present embodiment, the differences from Embodiments 1 and 2 will be described regarding the winding method of the field coil 10 .

[0108] structure

[0109] In the electric blower 1, the field windings 10 are arranged in a triangular arrangement in the spaces 30 and 32 inside the stator core 9. (The spaces 31 and 33 outside the stator core 9 or the coil ends on the upper and lower sides in the axial direction) are more preferable.

[0110] effect

[0111] By setting the winding state of the field winding 10 as described above, the outer shape of the stator core 9 (specifically, the lengths of the shoulders 9Ab, 9Ad, 9Bb, and 9Bd) can be reduced to improve efficiency and reduce weight. Next, the reason will be described in more detail.

[0112] The cross-sectional area of the space 30, 32 is approximately the product of the length of the arm portion (9Ac, 9Bc) and the length of the shoulder portion (9Ab, 9Ad, 9Bb, 9Bd). Since the length of the arms (9Ac, 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com