Welding fixture for automobile steering system

A technology of automobile steering system and welding fixture, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large cumulative system error, inaccurate product size, waste of time and manpower, etc., and achieve production The effect of performance improvement, labor intensity reduction, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

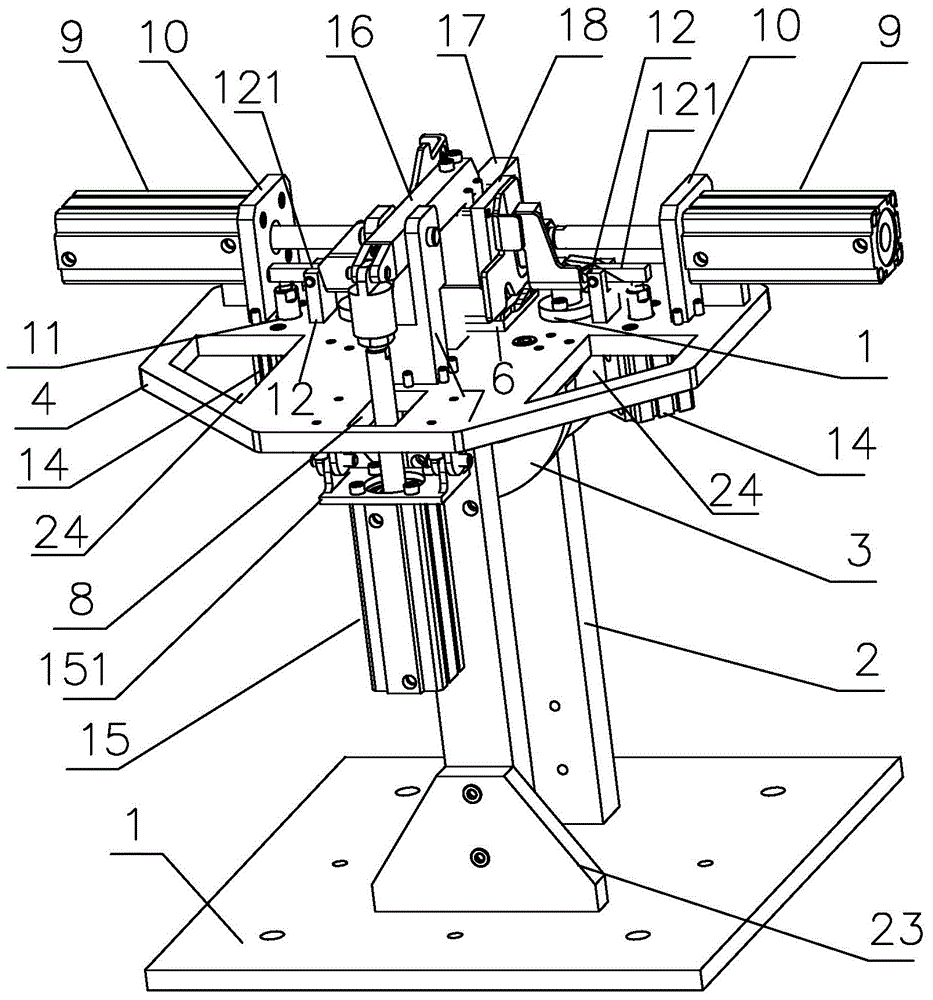

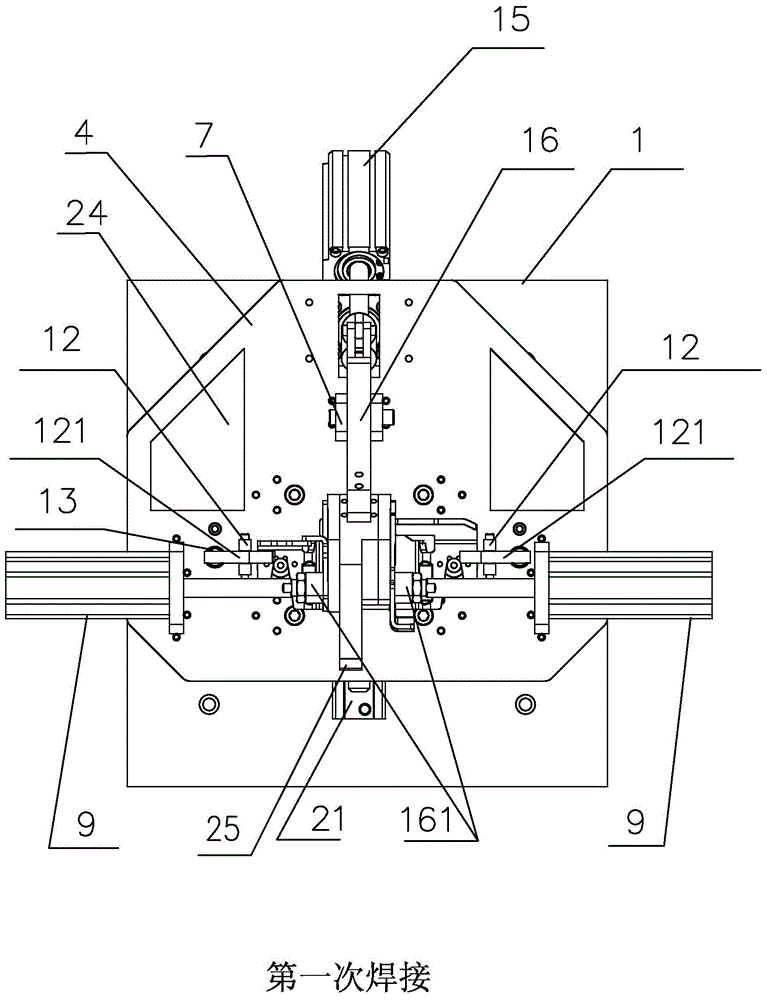

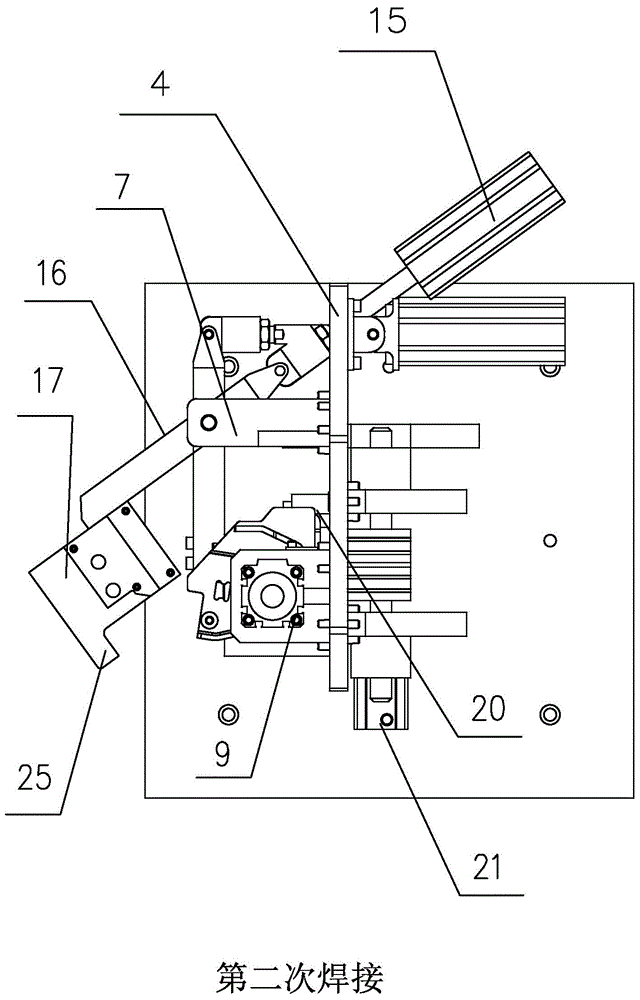

[0035] like figure 1 As shown, a welding fixture for an automobile steering system includes a bottom plate 1, two vertical plates 2 arranged side by side on the bottom plate, an overturning plate 3 arranged on the upper end of the vertical plate 2 through a main body rotating connection shaft, and an overturning plate arranged horizontally on the mounting plate 4;

[0036] Positioning slots, positioning plates 6, rotating brackets 7, through holes a8 and rotatable rotating mechanisms for fixing workpieces are sequentially provided on the central axis of the upper end surface of the mounting plate;

[0037] The mounting plates on both sides of the rotating mechanism are symmetrically provided with the cylinder b9, the cylinder mounting plate b10, the through hole c11, the pressing part bracket 12 and the circular positioning part 13 from far to near, and the push rod of the cylinder b is inward It is horizontally arranged on the cylinder mounting plate b, and a rod-shaped or p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com