Non-contact double-passage flow blocking device

A flow blocking device, non-contact technology, applied in valve device, valve operation/release device, multi-way valve, etc., can solve the problems of increasing pollution foreign matter, high labor cost, complex structure, etc., to improve work efficiency, Low production cost and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

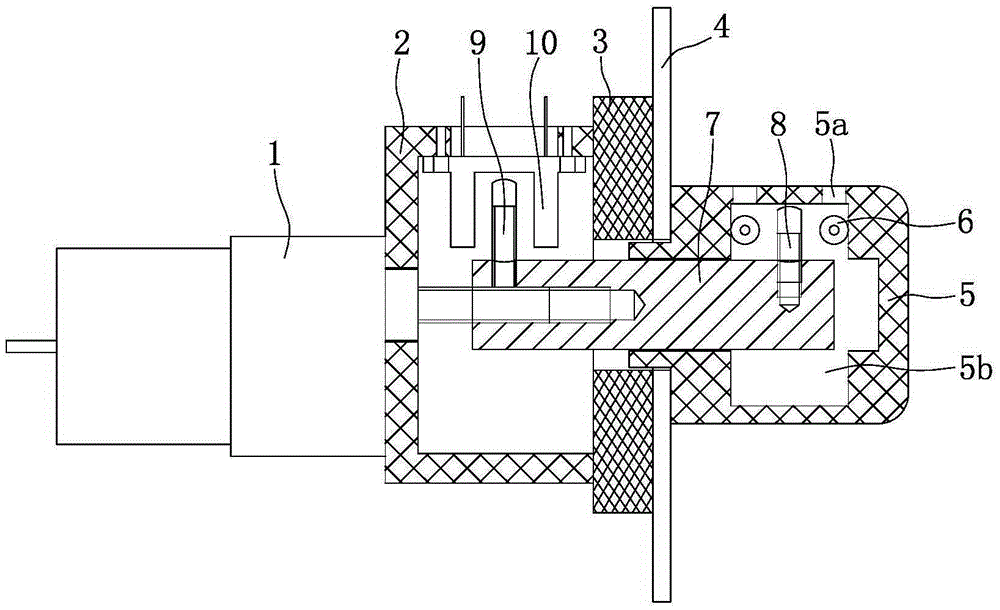

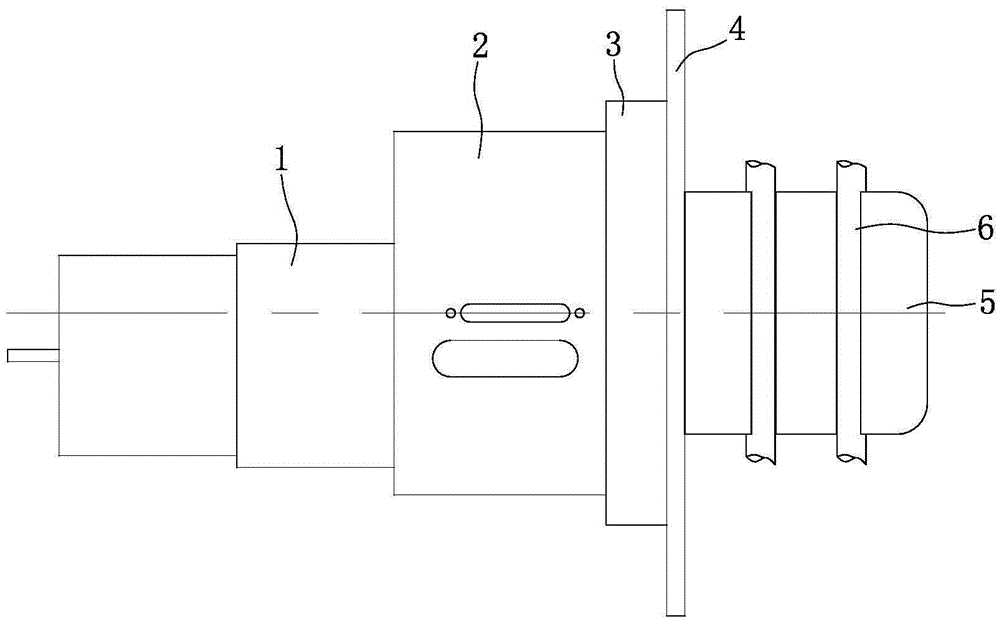

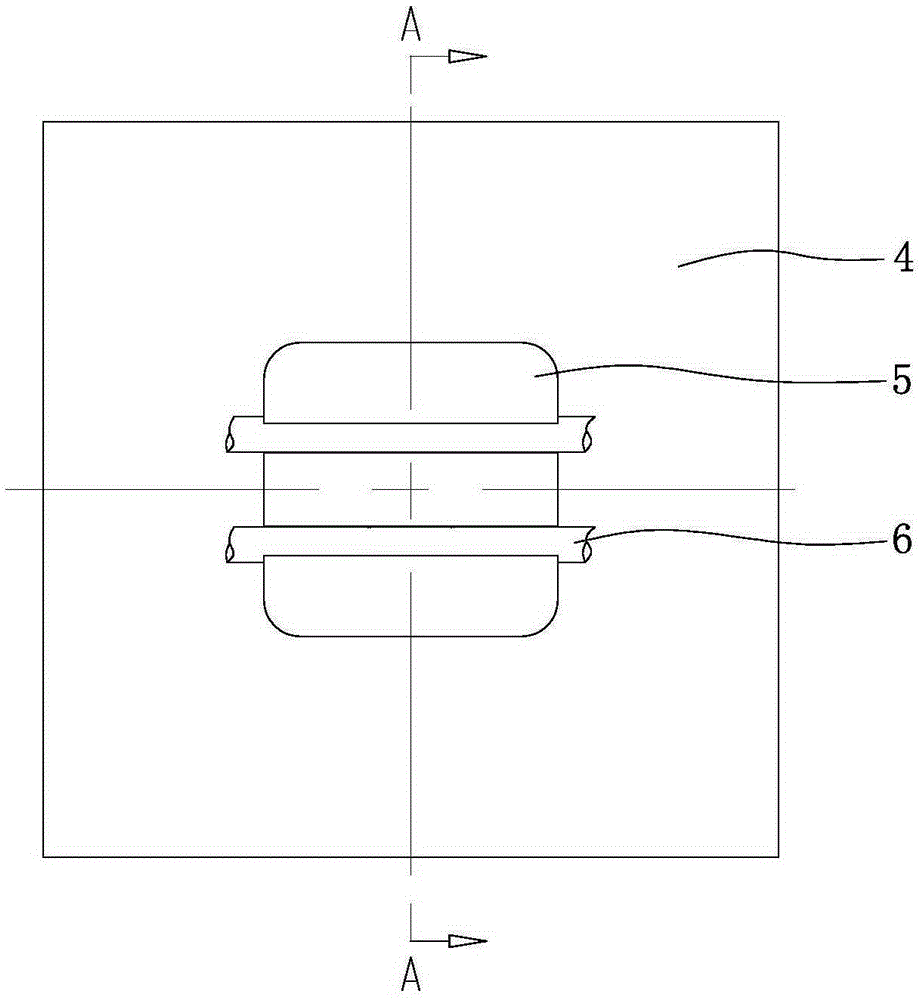

[0036] Such as figure 1 , figure 2 As shown, the housing 5 is located outside the box 4, and the housing 5 is preferably injection molded. An annular boss is integrally formed on the casing 5, and the annular boss extends into the box body 4, and the casing 5 is fixed to the box body 4 by a plurality of screws. On the top of the casing 5 are provided two locking grooves 5a for locking the pipeline 6 side by side, and the two locking grooves 5a are parallel to each other. The slot 5a is a through slot, and the bottom of the slot 5a communicates with the inner cavity 5b of the housing 5; the cross section of the bottom of the slot 5a is preferably circular, and the diameter of the bottom of the slot 5a is larger than the width of the notch.

[0037] Such as figure 1 , figure 2As shown, a fixed plate 3 is provided at a position corresponding to the outer shell 5 in the box body 4. The fixed plate 3 is a rectangular flat plate structure, and through injection molding, the fi...

Embodiment 2

[0042] Such as image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, two upper and lower locking grooves 5a parallel to each other are provided on the end surface of the housing 5 . The shaft coupling 7 is a cylinder, and the inner end of the shaft coupling 7 is inserted into the output shaft of the motor 1, and is tightened by radially threaded screws. Pin 9 is also installed at the inner end of shaft coupling 7, and this pin 9 is perpendicular to shaft coupling 7, and three position sensors 10 that inductively cooperate with pin 9 are fixed on the inner wall of motor fixed block 2, and these three position sensors 10 are in On the same circle, two of the position sensors 10 are located on a straight line, and the two position sensors 10 are perpendicular to the other position sensor 10 . The outer end of the shaft coupling 7 extends into the inner cavity 5b of the housing 5, and a blocking device is integrally formed at the outer end of the shaft coupling 7...

Embodiment 3

[0047] Such as Figure 8 and combine image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a blocking device is integrally formed at the outer end of the coupling 7, and the blocking device is Shaped blocking briquetting block 12. The blocking briquetting block 12 is made up of a transverse section and a longitudinal section, the transverse section is perpendicular to the longitudinal section, the middle part of the transverse section is integrated with the end of the longitudinal section, and the center of the transverse section is located on the axis of the shaft coupling 7 . The length of the transverse section is equal to the diameter of the shaft coupling 7, the length of the longitudinal section is half of the length of the transverse section, and the ends of the transverse section and the longitudinal section are rounded.

[0048] The rest of the structure of this embodiment is the same as that of Embodiment 2, and will not be repeated here.

[0049] The working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com