Experimental device and method for simulating single-crack flowback after shale gas fracturing

A single-fracture flowback and experimental device technology, applied in the direction of measurement devices, instruments, suspensions and porous material analysis, etc., can solve the problem of not considering the closure pressure, not considering the pressure drop proppant return flow settlement law, and not being able to simulate the fracture width and closing pressure changes, etc., to achieve the effect of comprehensive consideration and simple coring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

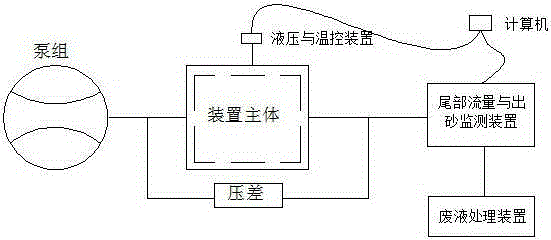

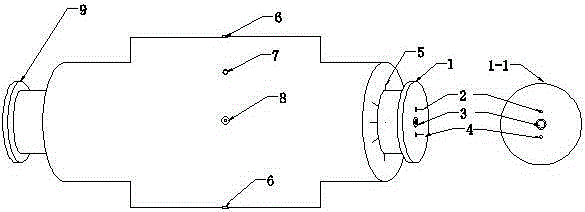

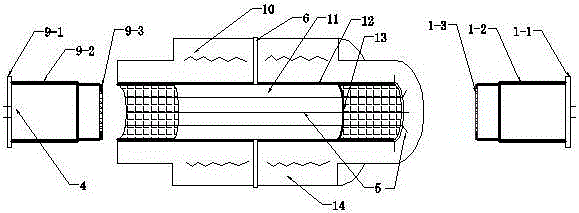

[0045] An experimental device for simulating single-seam flowback after shale gas pressure, which includes a pump set, a device main body, a hydraulic pressure and temperature control device, a tail monitoring device, and a waste liquid treatment device. The device main body and the tail monitoring device are connected to a computer; the device main body Mainly an improved core holder such as figure 2 , image 3 As shown, it is also an annular diversion chamber; the improved core holder includes a hydraulic pressure and temperature control device, the temperature in the cavity is controlled through 7 holes on the side, 8 holes are used to apply hydraulic pressure and monitor the internal pressure, and 6 holes are used to monitor The change of the crack width during the experiment; the side of the diversion chamber cavity 11 is wrapped with a rubber ring 12, and the rightmost end of the rubber ring is surrounded by a protruding rubber ring 13, which can fix the position of the...

Embodiment 2

[0054] An experimental device for simulating single-slit flowback after shale air pressure as described in Example 1, the difference is that the experimental device for simulating single-slit flowback after shale air pressure also includes hydraulic and temperature control devices, and a computer , Tail monitoring device, waste liquid treatment device. The hydraulic pressure and temperature control device, the pressure gauge and the displacement gauge are connected with the computer.

[0055] The hydraulic medium is water-glycol hydraulic oil. The fluid medium is on-site fracturing fluid. The sand production monitoring device is an acoustic sand production monitoring device. The pump set can steplessly adjust the flow rate and can withstand a certain pressure.

Embodiment 3

[0057] A kind of experimental method utilizing device as described in embodiment 2 to simulate the single seam flowback after shale air pressure, comprises steps as follows:

[0058] (1) Dry and weigh the marble core first, the mass is m 1 ;

[0059] (2) Spread proppants with different particle sizes in the designated area of the fracture according to a certain sanding concentration to realize the effective fracture width of the fracture and simulate the settlement law of proppants with different particle sizes during fracturing operations. The total amount of proppant added is The initial effective width of the fracture is divided by the fracture contact area;

[0060] (3) After the core rubber sleeve with proppant is aligned and fixed according to the scale, it is inserted into the annular diversion chamber according to the scale of the annular diversion chamber until the rightmost end cannot move, and the sealing clamping rods at both ends are screwed into the annular di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com