A system for simultaneous sampling and detection of no and mercury in flue gas from thermal power plants

A technology for thermal power plants and flue gas is applied in the field of environmental detection and sampling equipment, which can solve the problems of different sampling points for mercury and NO concentration, high sampling and detection costs, and no simultaneous NO and mercury sampling and detection systems have been developed. Achieving the effect of ensuring consistency and improving representativeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

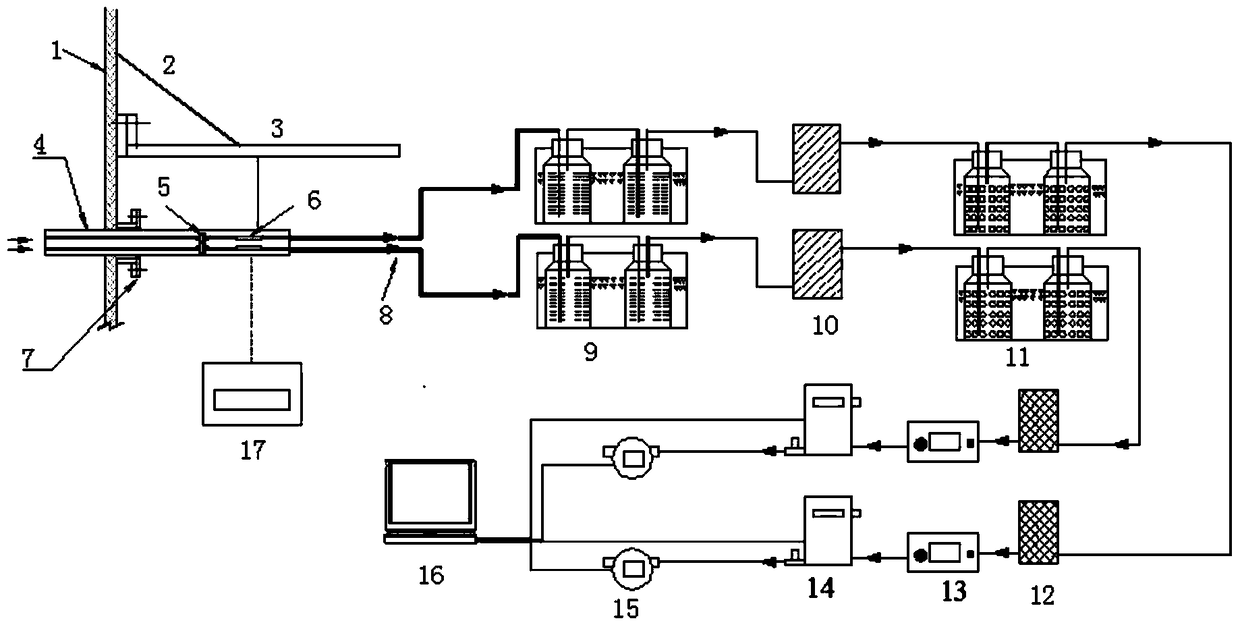

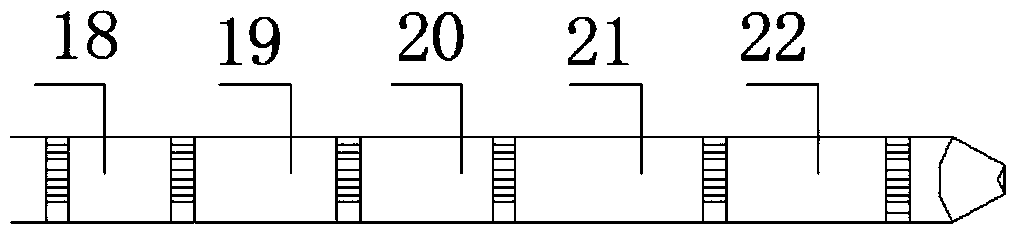

[0028] see figure 1, the present invention includes an off-line mercury measuring device and a sampling probe 4 for extending into the flue, the sampling probe 4 includes a housing and two independent quartz pipelines arranged in the housing and used to collect flue gas, each quartz A filter 5 and an activated carbon adsorption tube 6 filled with an adsorbent are sequentially installed on the pipeline along the flue gas flow direction; There is also a heating layer on the wall to keep the sampling probe 4 at 120-180°C. The heating layer is a heating wire wrapped with an aluminum radiator on the outer layer. When the temperature of the flue gas measured by the thermocouple is low, it can ensure that the sampling probe The temperature of the gun 4 is 120-180° C., preferably 140° C., so as to prevent the condensation of water vapor in the flue gas and cause the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com