Quantitative detection method and device for paint surface roughness

A quantitative detection method and surface smoothness technology, which is applied in the field of material surface flatness detection, can solve problems such as the inability to achieve quantitative detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

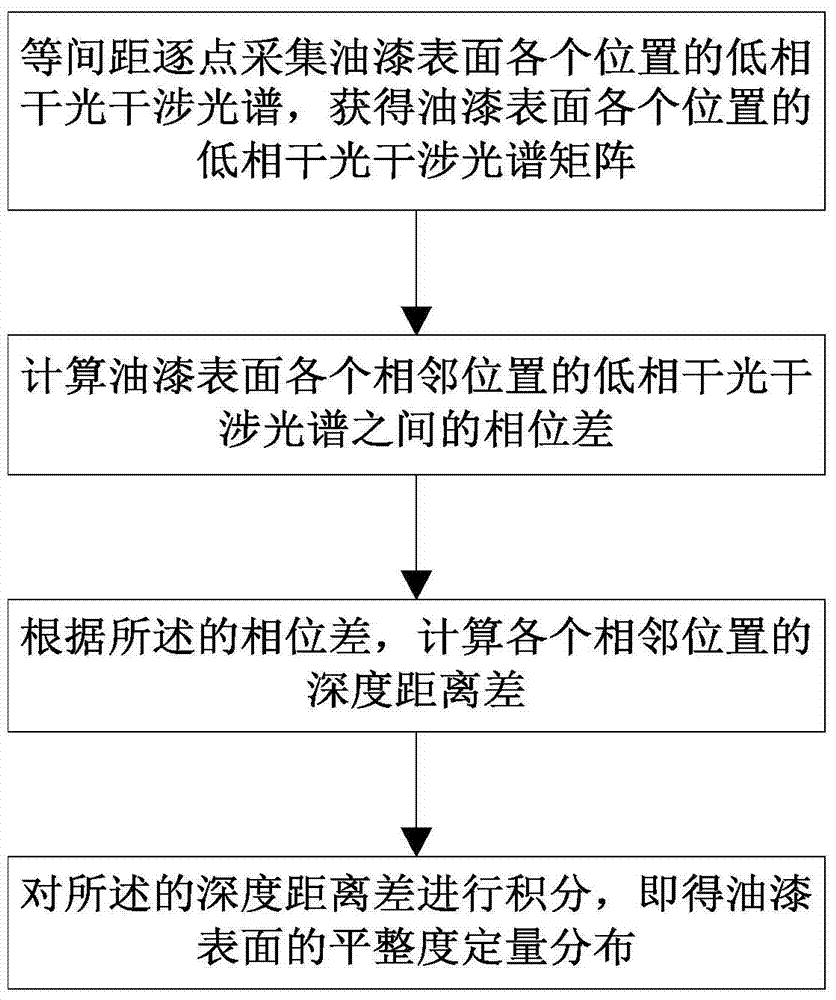

[0028] Embodiments of the present invention: a quantitative detection method for paint surface roughness, such as figure 1 shown, including the following steps:

[0029] S1, collect the low-coherent light interference spectrum of each position on the paint surface point by point at equal intervals, and obtain the low-coherence light interference spectrum matrix of each position on the paint surface;

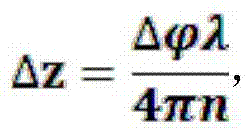

[0030] S2, calculate the phase difference between the low-coherence light interference spectra of each adjacent position on the paint surface It specifically includes the following steps: performing Fourier transform on the low-coherent light interference spectrum at adjacent positions to obtain a corresponding complex exponential function; dividing the complex exponential function to obtain; wherein,

[0031] The interference spectrum of low-coherence light at position 1 is:

[0032] The interference spectrum of low-coherence light at position 2 is: In the formula, I 1 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com