Novel baffle-rod longitudinal-flow shell-and-tube heat exchanger

A shell-and-tube heat exchanger and baffle rod technology are used in heat exchanger shells, heat exchanger sealing devices, heat exchange equipment, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation of the present invention will be further described in detail below in conjunction with the embodiments and drawings, but the present invention is not limited.

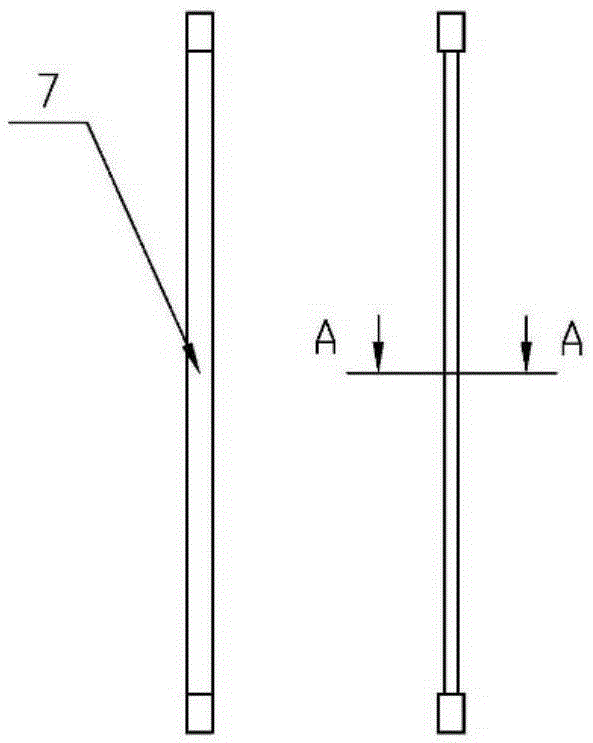

[0034] The novel baffle rod longitudinal flow shell-and-tube heat exchanger provided by the present invention is an adjustable baffle rod longitudinal flow shell-and-tube heat exchanger, and its structure is as follows: Figure 1 to Figure 6 As shown, it includes: a shell 8, a heat exchange tube 5 located in the inner cavity of the shell 8, a tube plate connected to both ends of the shell 8 by bolts, and a certain distance (for example, 0.5 meters) arranged in the shell 8 The baffle rod 7.

[0035] The tube sheets at both ends of the shell 8 are respectively the left tube sheet 3 and the right tube sheet 10 , wherein: the left tube sheet 3 is connected to the left end cover 2 with the tube-side fluid inlet 1 by bolts. The right tube plate 10 is connected with the right end cover 11 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com