Nine-stage transmission

A transmission and brake technology, which is applied in the direction of vehicle transmission, gear transmission, transmission control, etc., can solve the problems of slow shift response speed, small transmission ratio range, obvious shift frustration, etc., and achieve shift response speed Fast, good fuel economy, good car handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

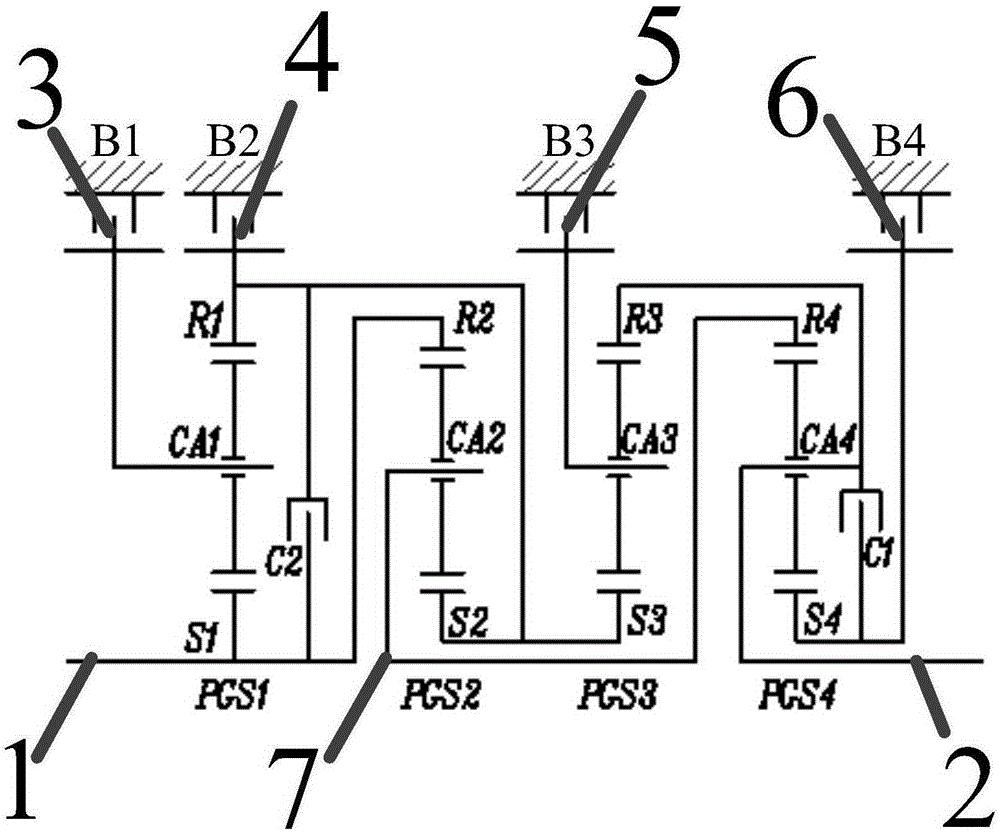

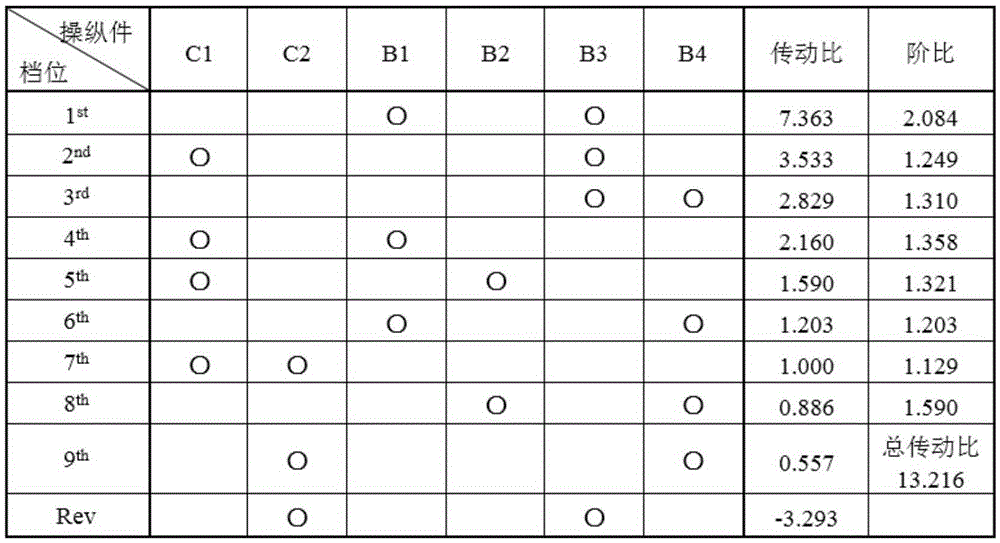

[0052] Such as figure 1 As shown, a nine-stage transmission includes a planetary row, an input member 1 and an output member 2 installed at both ends respectively connected to the corresponding input shaft and output shaft; a transmission member, a brake and a clutch,

[0053] The planetary rows are: planetary row PGS1 to planetary row PGS4;

[0054] The transmission components are: transmission components 3 to 7;

[0055] The brakes include brakes B1 to B4;

[0056] The clutches include a clutch C1 and a clutch C2.

[0057] The planetary row PGS1 includes a sun gear S1 connected to the input member 1, a planet carrier CA1 connected to the transmission member 3, and a ring gear R1 connected to the transmission member 4;

[0058] The planetary row PGS2 includes a sun gear S2 connected to the transmission member 4, a planet carrier CA2 connected to the transmission member 7, and a ring gear R2 connected to the input member 1;

[0059] The planetary row PGS3 includes a sun ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com