Annular screen

A technology of annular screen and screen, applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problems of poor filtering effect, frequent replacement, short service life, etc., to reduce the production cost and extend the The effect of service life and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

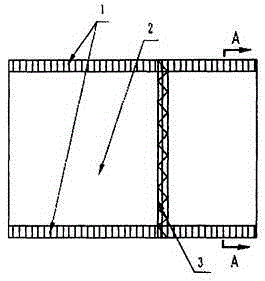

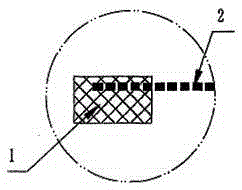

[0017] Such as figure 1 As shown, a ring-shaped screen is composed of a transmission belt 1, a screen 2 and a connecting part 3; the side of the screen 2 is connected to the transmission belt 1 by bonding to become one; as figure 2 , 3 As shown, the side of the screen 2 is buried in the middle of the conveyor belt 1; the connecting part 3 is arranged on the screen 2 by sewing, and the two ends of the screen are connected through the connecting part to form a closed ring-shaped ring screen network.

[0018] The endless screen conveyer belt of the present embodiment selects flat belt, and the screen adopts metal mesh.

[0019] The annular screen of the present invention can also adopt an integral forming mode to prefabricate a closed ring annular screen.

[0020] The working principle of the ring-shaped screen of the present invention is: the ring-shaped screen forms a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com