Seismic strengthening method for frame beam-column joint core area

A technology for beam-column joints and core areas, which is applied in earthquake resistance, building maintenance, building components, etc., can solve the problems of weak seismic performance, easy leakage binding, destructive damage, etc., and achieves simple construction, avoids construction difficulties, and is easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further describe the present invention, it is further described below in conjunction with embodiment.

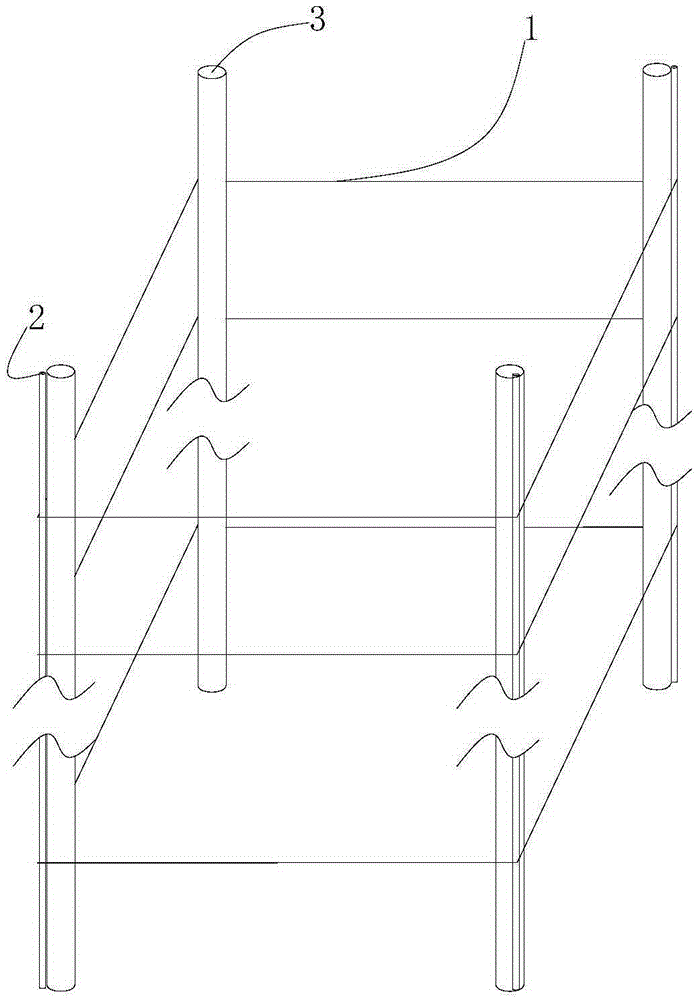

[0015] Such as figure 1 As shown, a method for seismic strengthening of the core area of a frame beam-column joint includes the following steps:

[0016] S1. Prefabrication of the overall stirrup cover 1: select four steel bar heads 2 of equal length as the skeleton, set several square stirrup cover 1s equidistantly around the outer circumference of the four steel bar heads 2, and place the four steel bar heads 2 Reserve 10cm at both ends, and fix the steel bar head 2 with the inner four corners of the stirrup cover 1 by spot welding. When making the stirrup cover 1, the bending angle of the hook of the stirrup cover 1 is 135°, and the hook The length is the larger of 10d and 75mm, and d is the diameter of the reinforcing bar for making the stirrup cover 1. When spot welding the inner four corners of the steel bar head 2 and the stirrup cover 1, the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com