Liquid lubricant for drilling fluid and preparation method of liquid lubricant

A lubricant and drilling fluid technology, applied in the field of water-based drilling treatment fluid, can solve the problems of difficult and weak varieties and performance, and achieve the effects of improving lubrication performance, reducing drilling costs, and reducing oil-water interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

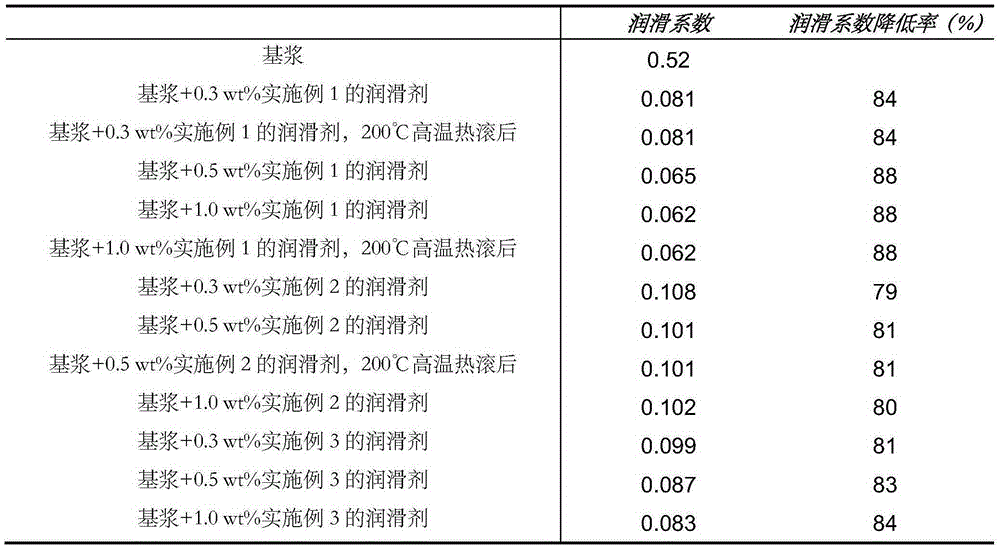

Embodiment 1

[0016] Embodiment 1: A kind of liquid lubricant for drilling fluid

[0017] A liquid lubricant for drilling fluid, which is made of the following raw materials in parts by weight: 550 parts of methyl oleate, 200 kg of silicone oil, 200 kg of white oil, 50 kg of overstock oil, 60 kg of emulsifier S-8060 parts, and 1060 parts of surfactant OP- , Masking agent 18kg.

[0018] The preparation method of the above-mentioned liquid lubricant is as follows: add 550kg of methyl oleate, 200kg of silicone oil, 200kg of white oil, and 50kg of overstocked oil into the enamel stirring kettle, stir and heat up to 55-60°C, keep warm and stir for 30min, and add emulsifying Agent S-8060kg, surfactant OP-1060kg, masking agent 18kg, just stir evenly.

Embodiment 2

[0019] Embodiment 2: A kind of liquid lubricant for drilling fluid

[0020] A liquid lubricant for drilling fluid, which is made of the following raw materials in parts by weight: 580 parts of methyl oleate, 220 kg of silicone oil, 220 kg of white oil, 70 kg of overstock oil, 80 kg of emulsifier S-8080 parts, and 1080 parts of surfactant OP- , Masking agent 20kg.

[0021] The preparation method of the above-mentioned liquid lubricant is as follows: add 580kg of methyl oleate, 220kg of silicone oil, 220kg of white oil, and 70kg of overstock oil into the enamel stirring kettle, stir and heat up to 55-60°C, keep stirring for 30min, visually observe that the mixture is uniform, and then add emulsification Agent S-8080kg, surfactant OP-1080kg, masking agent 20kg, just stir evenly.

Embodiment 3

[0022] Embodiment 3: A kind of liquid lubricant for drilling fluid

[0023] A liquid lubricant for drilling fluid, which is made of the following raw materials in parts by weight: 500 parts of methyl oleate, 180 kg of silicone oil, 180 kg of white oil, 40 kg of overstock oil, 70 kg of emulsifier S-8070 parts, and 1070 parts of surfactant OP- , Masking agent 16kg.

[0024] The preparation method of the above-mentioned liquid lubricant is as follows: add 500kg of methyl oleate, 180kg of silicone oil, 180kg of white oil, and 40kg of overstocked oil into the enamel stirring kettle, stir and heat up to 55-60°C, keep stirring for 30min, visually observe and stir evenly, and then add emulsification Agent S-8070kg, surfactant OP-1070kg, masking agent 16kg, just stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com