Non-contact wheel set dimension online detection method and device based on various sensors

A non-contact, detection method technology, applied in the field of traffic safety engineering, can solve the problems of many sensors, large-scale equipment, not suitable for the actual situation of the subway company, etc., achieve simple measurement principle, low cost, improve detection efficiency and measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

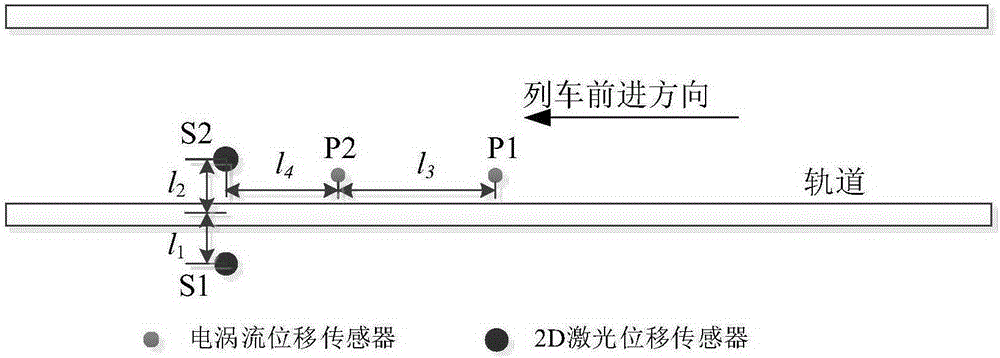

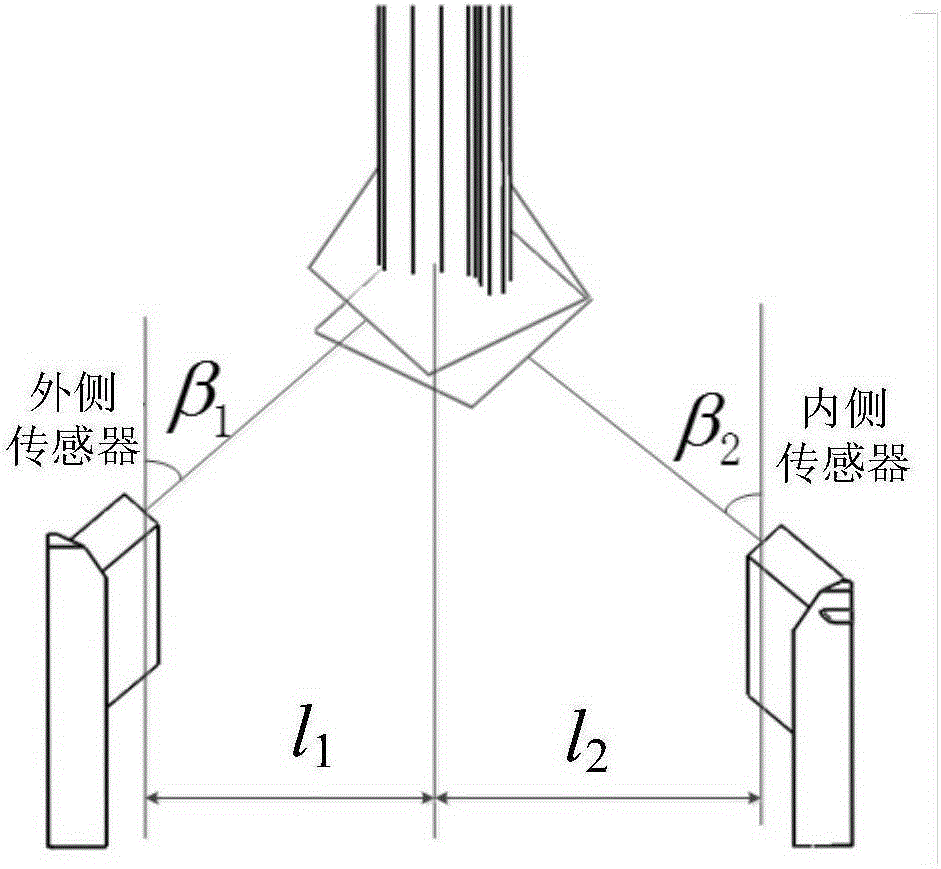

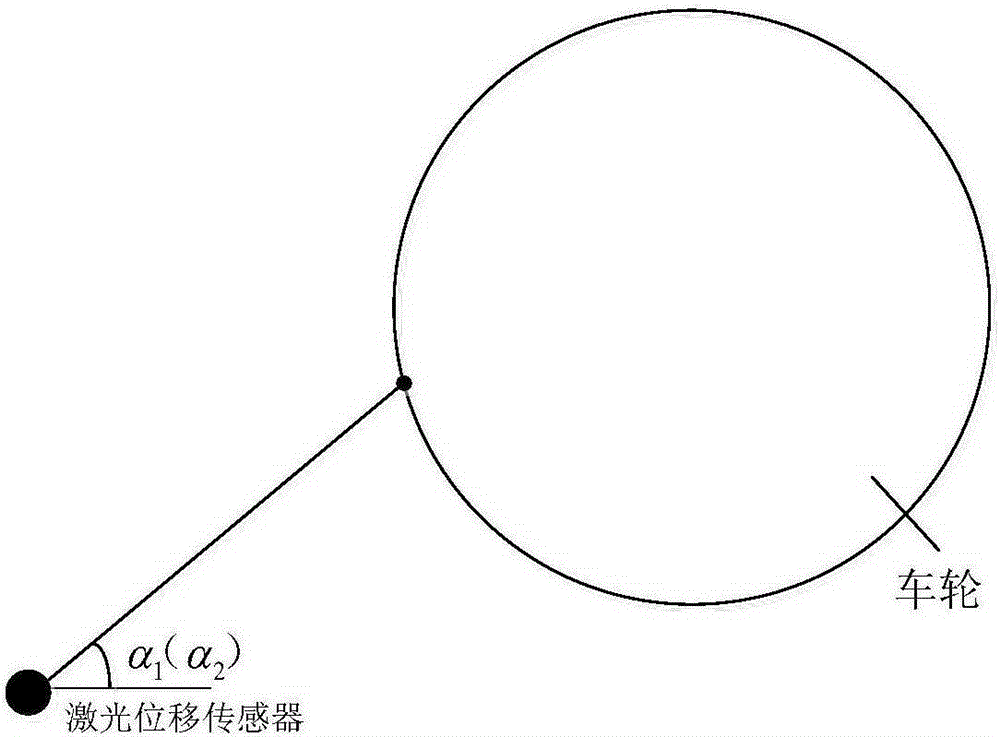

[0057] combine Figure 1~3 , install the first eddy current displacement sensor P1, the second eddy current displacement sensor P2, and the second laser displacement sensor S2 in sequence along the train advancing direction. The distance between the first eddy current displacement sensor P1 and the second eddy current displacement sensor P2 is 150 mm. The distance between the second eddy current displacement sensor P2 and the second laser displacement sensor S2 is 250 mm. The first laser displacement sensor S1 and the second laser displacement sensor S2 are installed on both sides of the track at an angle of 45° to the vertical line, and the angle with the straight line along the direction of the track is 47°, then β 1 , β 2 is 45°, α 1 、α 2 is 47°, and the vertical distance from the track is 250mm. The sampling frequency of laser displacement sensor and eddy current displacement sensor is the same, both are 200Hz.

[0058] After the first laser displacement sensor S1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com