Stable automatic drilling device for side wall of board

A drilling device and plate technology, which is applied to fixed drilling machines and other directions, can solve the problems of low flexibility, difficulty in ensuring manual work efficiency and work quality, and inability to achieve high efficiency effects, and achieve the effects of convenient use and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

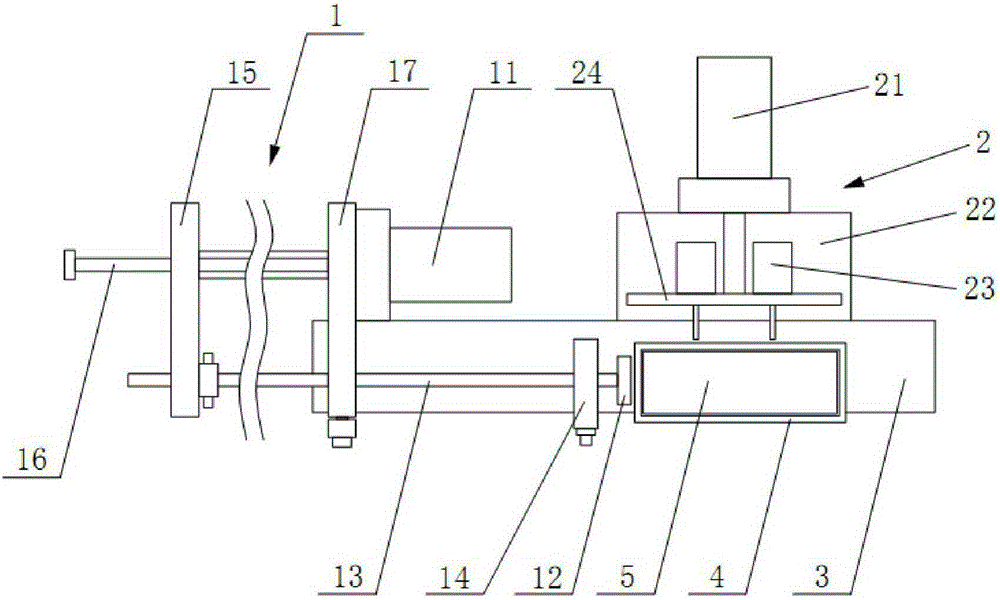

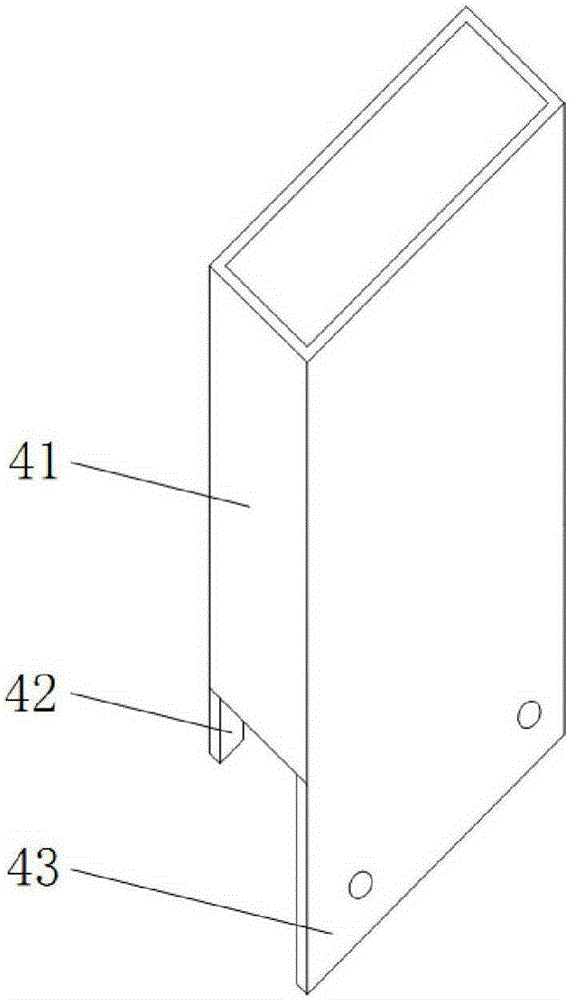

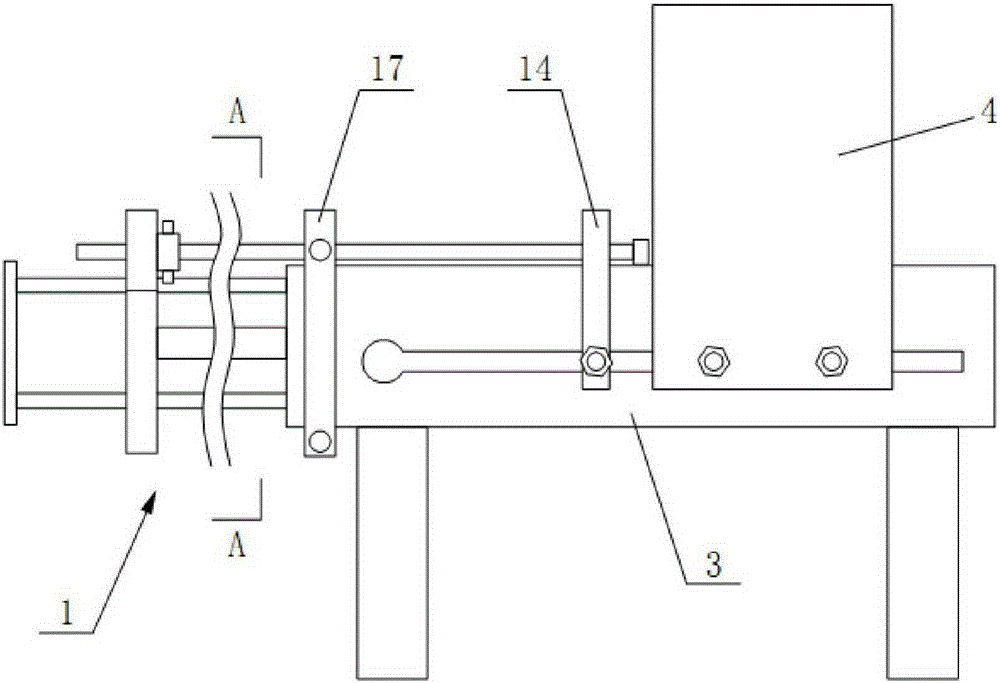

[0021] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, an automatic drilling device for stabilizing the side wall of a plate includes a workbench 3, a pushing component 1, a drilling component 2 and a raw material bin 4, the raw material bin 4 is set above the workbench 3, and the pushing component 1 is set on the raw material bin 4 On the workbench 3 outside one end, the drilling assembly 2 is arranged on the workbench 3 outside the side of the raw material to be drilled. The push assembly 1 includes a pneumatic cylinder 11, a connecting plate 15, a guide plate 14, a push rod 13 and a pushing plate 12. The pneumatic cylinder 11 is arranged on the workbench 3, and one end of the piston rod of the pneumatic cylinder 11 is fixed to the connecting plate 15. Connection, one end of the push rod 13 is connected with the connecting plate 15, the other end passes through the guide plate 14 and connected with the push plate 12, the push plate 12 is located at the en...

Embodiment 2

[0023] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, an automatic drilling device for stabilizing the side wall of a plate includes a workbench 3, a pushing component 1, a drilling component 2 and a raw material bin 4, the raw material bin 4 is set above the workbench 3, and the pushing component 1 is set on the raw material bin 4 On the workbench 3 outside one end, the drilling assembly 2 is arranged on the workbench 3 outside the side of the raw material to be drilled. The push assembly 1 includes a pneumatic cylinder 11, a connecting plate 15, a guide plate 14, a push rod 13 and a pushing plate 12, the pneumatic cylinder 11 is arranged on the workbench 3, and one end of the piston rod of the pneumatic cylinder 11 is fixed to the connecting plate 15 Connection, one end of the push rod 13 is connected with the connecting plate 15, and the other end passes through the guide plate 14 and is connected with the push plate one 12. The push plate one 12 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com