Shock-absorption circuit board assembly using contact sensor

A technology for contact sensors and circuit board components, applied in the direction of circuit layout, elastic/clamping devices, etc. on the support structure, which can solve the problem of affecting the wiring layout of the circuit board, affecting the mechanical strength of the circuit board, and unbalanced mechanical force on the circuit board, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

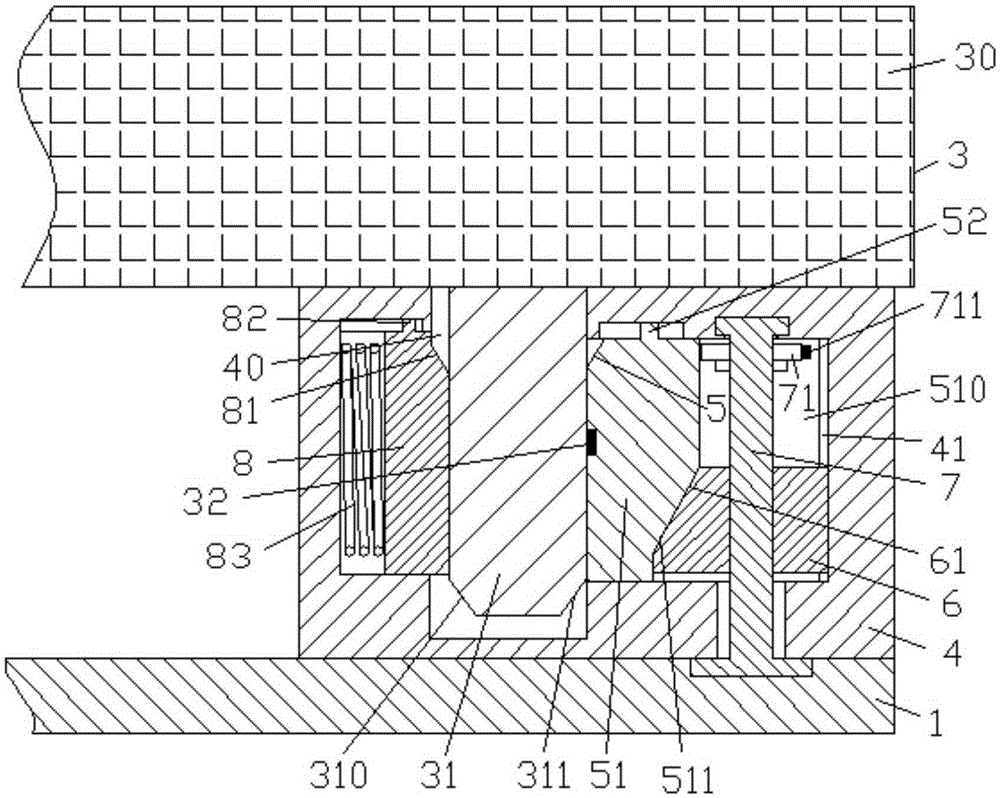

[0009] Combine below Figure 1-2 The present invention will be described in detail.

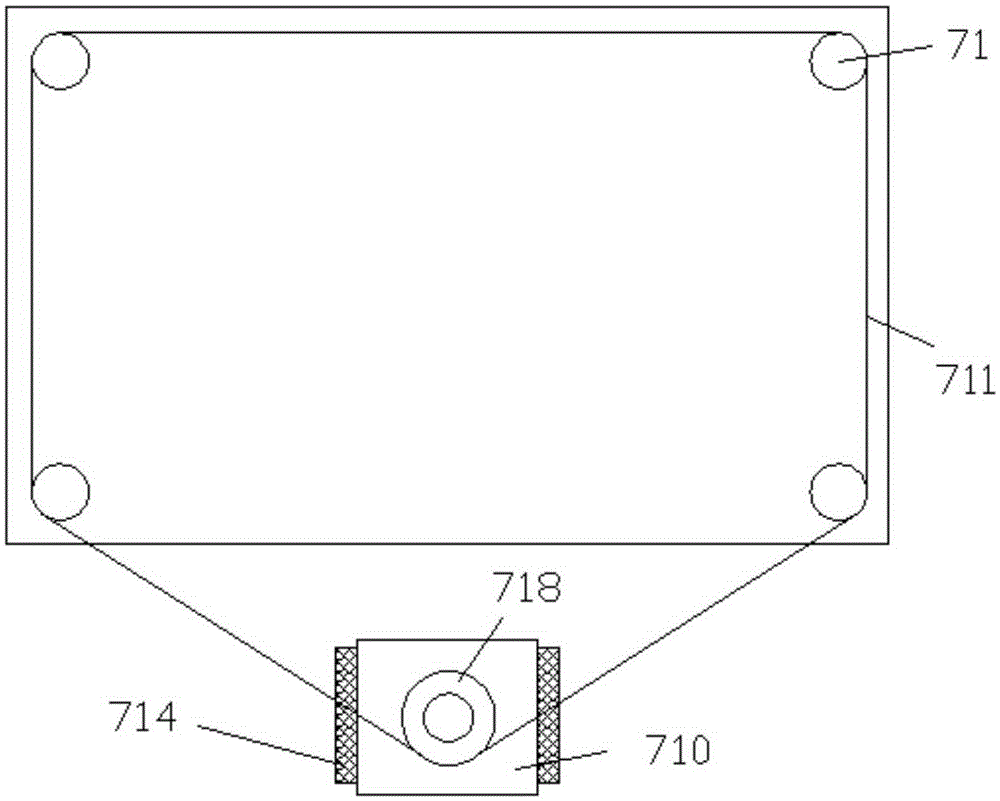

[0010] A shock-absorbing circuit board assembly using a touch sensor according to an embodiment includes a circuit board device 3 and a base fixing device. The circuit board device 3 includes a rectangular body part 30 and four corners of the rectangle respectively four fixing feet 31, the base fixing device includes a base 1 and four mounting frames 4 fixed on the base 1 and corresponding to the four fixing feet 31 respectively, the mounting frame 4 is provided with useful The slot 40 for the insertion of the fixing pin 31, the mounting frame 4 is provided with a biasing spring 83 at the inner part of the slot 40 close to the inner side of the body part 30 of the circuit board device 3 and can The inner clamping block 8 protruding into the slot 40, the upper side of the inner clamping block 8 is provided with a first stop protrusion 82 for cooperating with the chute in the mounting bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com