NiO@PANI@ZnO three-dimensional nano composite material and preparation method thereof

A composite material, three-dimensional nanotechnology, applied in nanotechnology, nanotechnology, analytical materials, etc., can solve the problems of low sensitivity, limit the development and popularization of nano-ZnO, and achieve low preparation cost, excellent biosensing performance, and improved The effect of detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

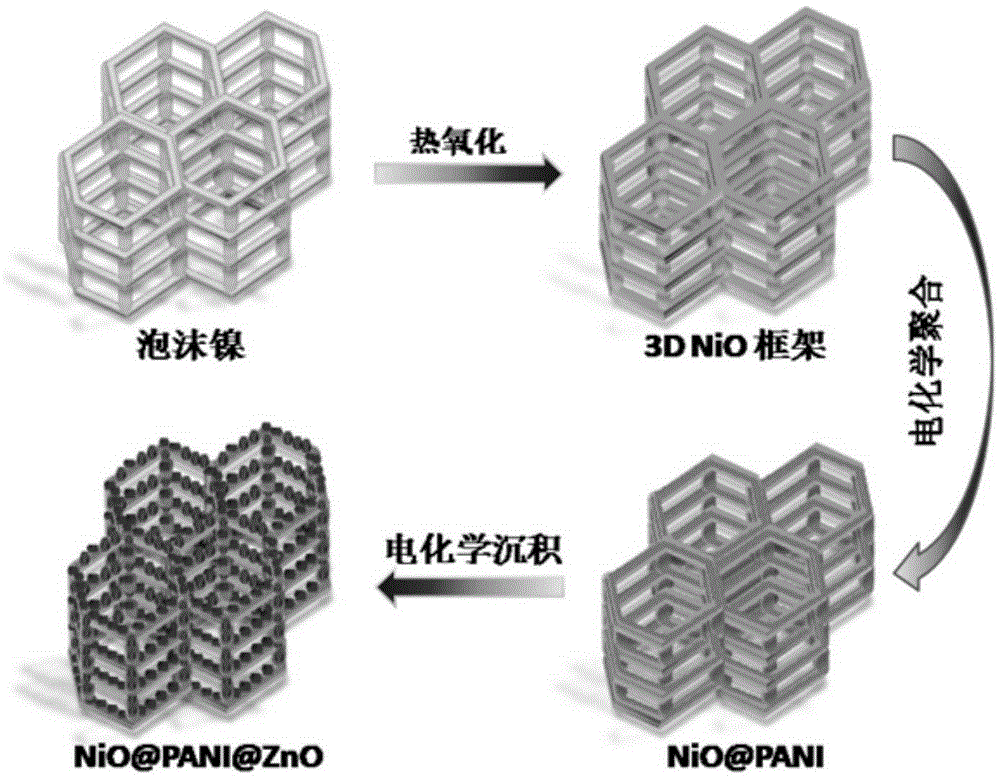

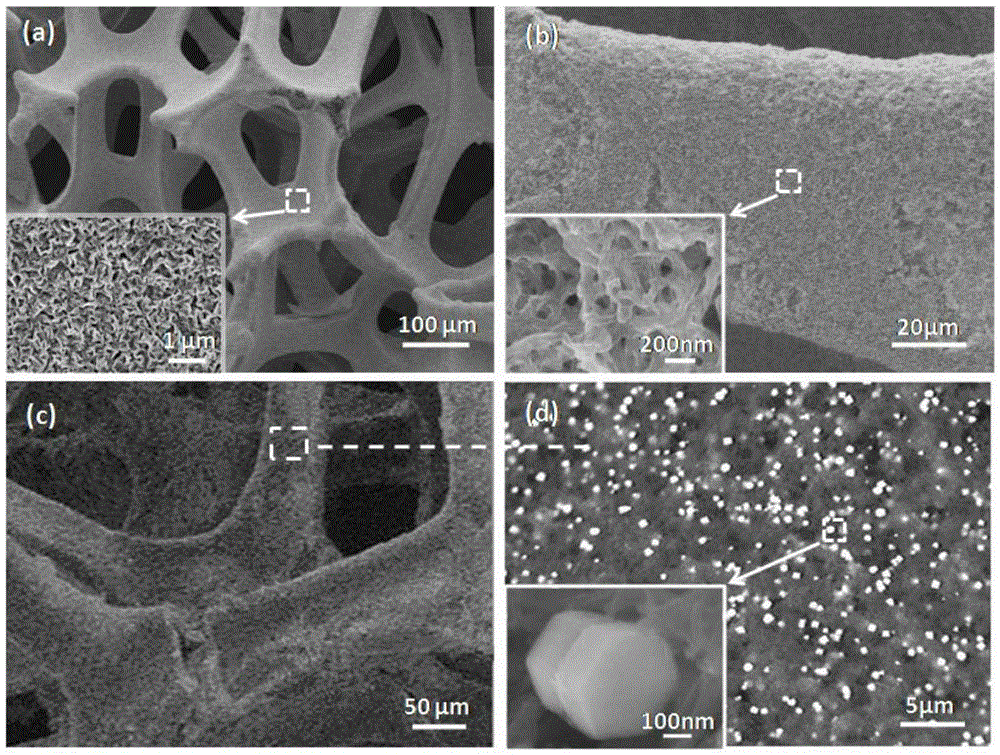

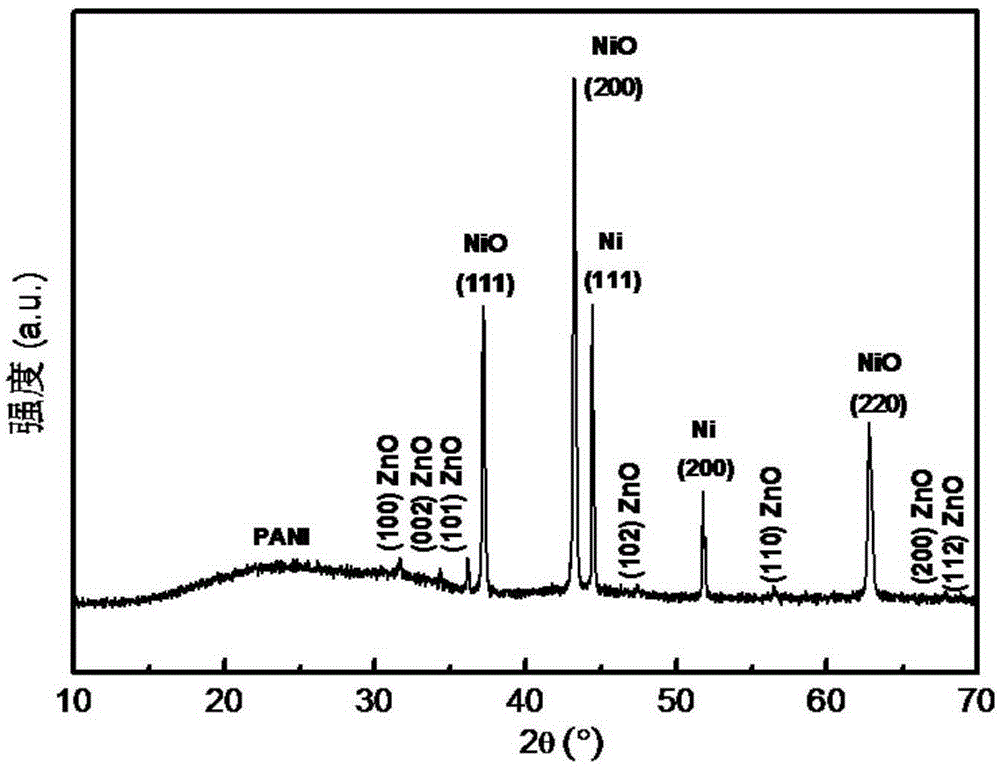

[0038] The specific preparation process of the present invention is as figure 1 shown. Take the surface area of about 1cm 2 The nickel foam was ultrasonically cleaned with ethanol and deionized water for 10 minutes, dried with nitrogen, and sintered in a tube furnace at 700 °C for 4 hours in an air atmosphere to obtain a 3DNiO framework. from SEM figure 2 (a) It can be seen that the 3DNiO framework has a large number of pores and a large specific surface area, which is conducive to contact with biomolecules and hole transfer.

[0039]A three-electrode system is adopted, with a 3DNiO frame as the working electrode, a Pt electrode and an Ag / AgCl electrode as the counter electrode and a reference electrode, respectively, the electrolyte is 0.3M aniline solution, and 0.5M HCl is added to make the pH figure 2 (b) It can be seen that the PANI membrane with a thickness of about 10 microns is evenly covered on the surface of NiO. It can be seen from the enlarged illustration that...

Embodiment 2

[0044] Take the surface area of about 1cm 2 The nickel foam was ultrasonically cleaned with ethanol and deionized water for 10 minutes, dried with nitrogen, and sintered in a tube furnace at 700 °C for 5 hours in an air atmosphere to obtain a 3DNiO framework. Experiments have shown that changing the sintering time within a certain range will not affect the synthesis of materials.

[0045] A three-electrode system is adopted, with a 3DNiO frame as the working electrode, a Pt electrode and an Ag / AgCl electrode as the counter electrode and a reference electrode, respectively, the electrolyte is 0.3M aniline solution, and 0.5M Hcl is added to make the pH<1. The electrochemical polymerization potential is 1.2V, polymerized at 35-40°C for 10min, washed twice with ethanol and deionized water respectively, and dried in an oven at 40°C for 12h. Experiments show that properly prolonging the electrochemical polymerization time can increase the thickness of PANI film.

[0046] The thr...

Embodiment 3

[0048] Take the surface area of about 1cm 2 The nickel foam was ultrasonically cleaned with ethanol and deionized water for 10 minutes, dried with argon, and sintered in a tube furnace at 700 °C for 4 hours in an air atmosphere to obtain a 3DNiO framework. Experiments have proved that using different inert gases to dry nickel foam does not change the structure and properties of the 3DNiO framework.

[0049] A three-electrode system is adopted, with a 3DNiO frame as the working electrode, a Pt electrode and an Ag / AgCl electrode as the counter electrode and a reference electrode, respectively, the electrolyte is 0.3M aniline solution, and 0.5M Hcl is added to make the pH2 SO 4 Substitution of HCl does not change the structural characteristics and properties of the PANI membrane.

[0050] The three-electrode system is also used, with the prepared 3DNiOPANI as the working electrode, the Pt electrode and the Ag / AgCl electrode as the counter electrode and the reference electrode,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com