Double-layer oil storage tank

An oil storage tank, double-layer technology, applied in the field of liquid storage containers, can solve problems such as failure to alarm in time, uneven heating of the oil tank body, leakage, etc., to reduce temperature rise and uneven temperature distribution, good heat reflection and The effect of thermal conductivity characteristics and simple construction and operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

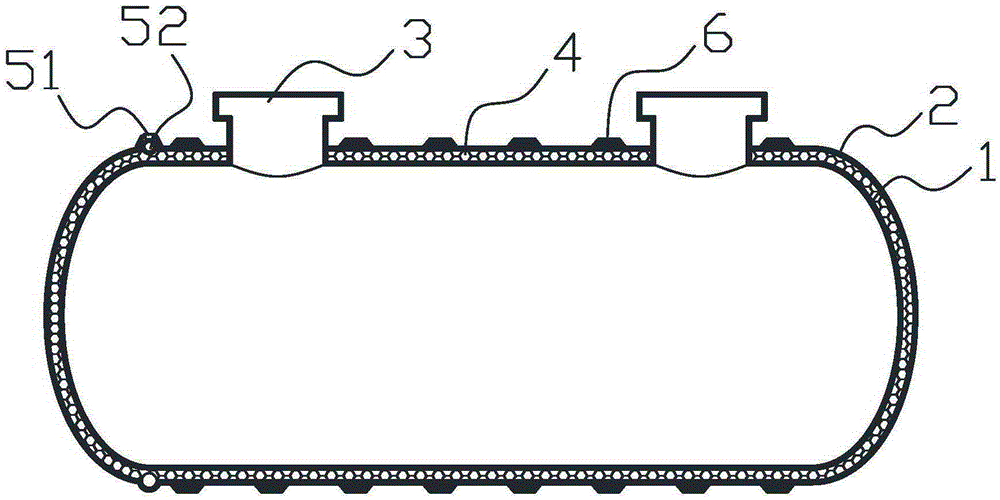

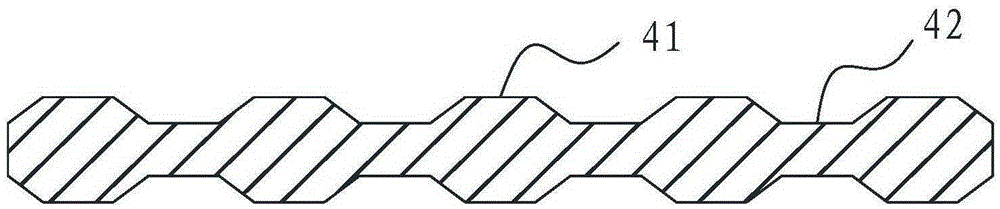

[0031] reference figure 1 , A double-layer oil storage tank of the present invention, a tank body and a manhole 3, the tank body includes an inner tank 1, an outer tank 2 and an intermediate layer 4. The inner tank 1 and the outer tank 2 are both glass fiber reinforced plastic tanks made by spray forming process. The glass fiber reinforced plastic oil tanks are better than metal tanks in terms of resistance to internal and external corrosion. Wherein, the inner tank 1 is spray-formed through a spraying process, so that the composition of the inner tank 1 is uniform, and the forming density is high, which is suitable for long-term storage of oil. A manhole 3 is formed on the upper circumferential surface of the side of the tank body. The double-layer oil storage tank in this embodiment includes two manholes 3, which facilitates the staff to enter and exit the oil tank or ventilate during installation, cleaning, and maintenance. In this embodiment, the intermediate layer 4 is an ...

Embodiment 2

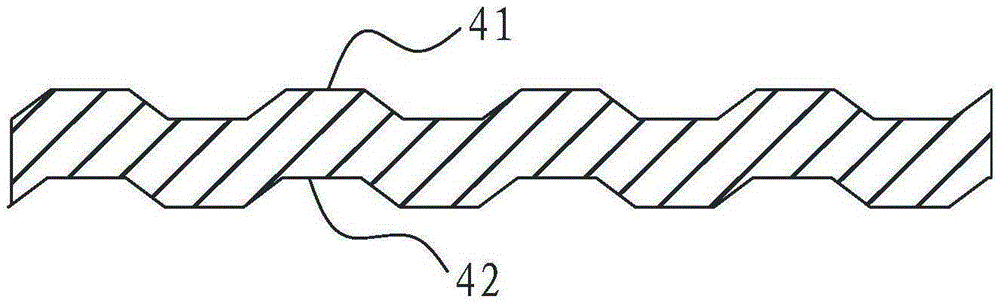

[0033] The difference between this embodiment and the first embodiment is as follows: image 3 As shown, the concave-convex structure on the inner surface of the intermediate layer 4 and the concave-convex structure on the outer surface are arranged in a staggered manner. The convex end 41 of the concave-convex structure on the inner surface corresponds to the concave end 42 of the outer surface. Corresponding to the convex end 41 on the outer surface, this arrangement structure can keep the thickness of the intermediate layer 4 unchanged, and the intermediate layer 4 will not be broken due to stress concentration caused by the force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com