A vertically-opening ice breaking high-voltage isolation switch

A high-voltage isolation switch and crampon technology, which is applied to switches with movable electrical contacts, etc., can solve the problems of hidden safety hazards, long ice melting time, and inability to achieve ice breaking, and achieves fast ice breaking, reliable operation, and simple structure. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings.

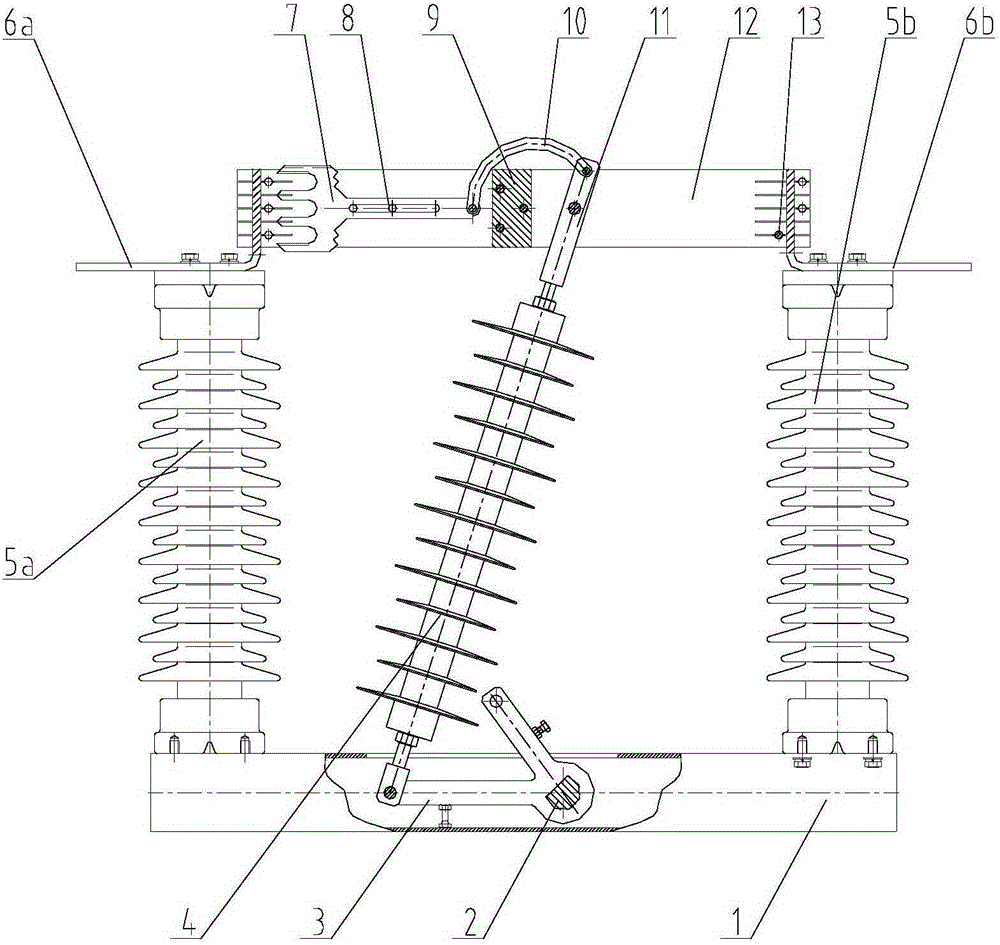

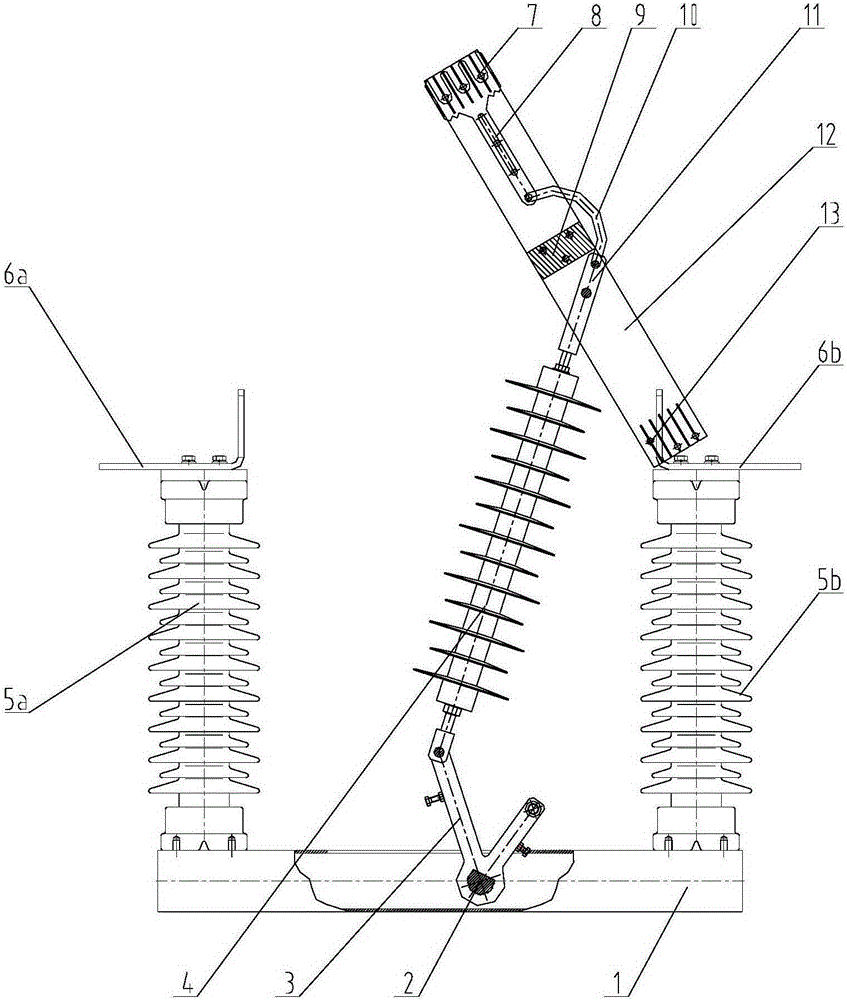

[0017] A structure for vertically opening the ice-breaking high-voltage isolating switch such as figure 1 As shown, two support insulators (5a and 5b) are fixed on the chassis 1, and conductive static contacts (6a and 6b) are fixed on the two support insulators. One end of the conductive arm 12 is hinged to a conductive The static contact 6b has a spacer 9 between the two conductive arms. The crank arm shaft 2 is installed on the chassis 1, the crank arm 3 is fixed on the crank arm shaft 2, one end of the operating insulator 4 is hinged to the crank arm 3, the other end is fixed to one end of the operating pull rod 11, and the other end of the operating pull rod 11 is hinged to the conductive arm 12.

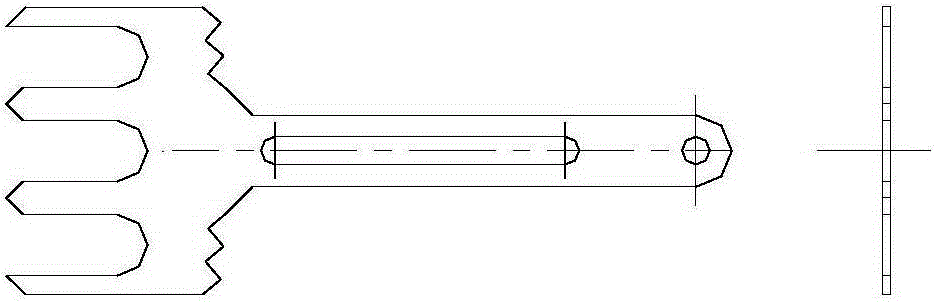

[0018] Crampons 7 are arranged in the inner movable contact area of the conductive arm 12, and the crampons move longitudinally along the conductive arm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com