Cam diaphragm vacuum valve for pressure casting

A technology of vacuum valve and diaphragm, which is applied in the direction of valve details, valve device, valve operation/release device, etc. It can solve the problems of large thread stroke, inconvenient vacuum valve to open and close quickly, and slow opening and closing speed, so as to achieve good airtightness performance, easy to manufacture and install, and easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

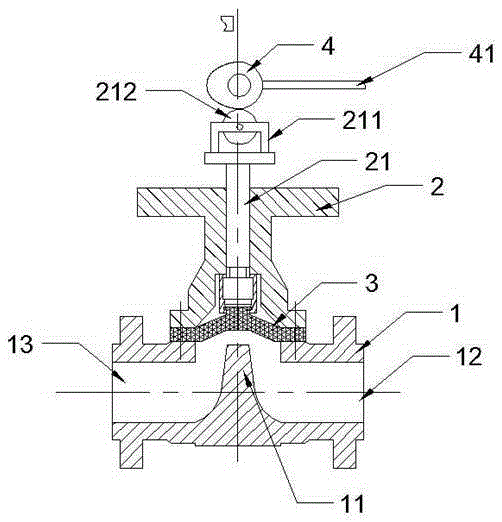

[0013] The reference signs in the accompanying drawings include: lower valve body 1, valve core 11, air inlet 12, air outlet 13, upper valve body 2, valve stem 21, support frame 211, pulley 212, diaphragm 3, cam 4, handle41.

[0014] The embodiment is basically as attached figure 1 Shown:

[0015] The cam diaphragm vacuum valve for die-casting in this solution includes a diaphragm 3 and a valve stem 21, the valve stem 21 is sleeved in the upper valve body 2, the lower end of the valve stem 21 is connected to the diaphragm 3, the valve core 11 is located below the diaphragm 3, and the valve core 11 It is integrally formed with the lower valve body 1. The two sides of the valve core 11 are respectively provided with an air inlet 12 and an air outlet 13. The air inlet 12 and the air outlet 13 are connected through the gap between the valve core 11 and the diaphragm 3. . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com