A segmented anchoring grouting bolt device capable of automatic clamping and its anchoring method

A grouting bolt and anchoring technology, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., to achieve the effects of strong controllability, saving support costs, and improving segmental anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

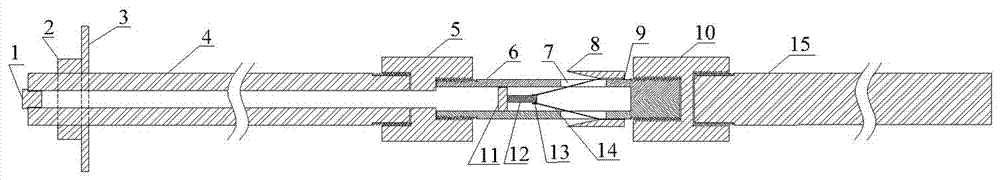

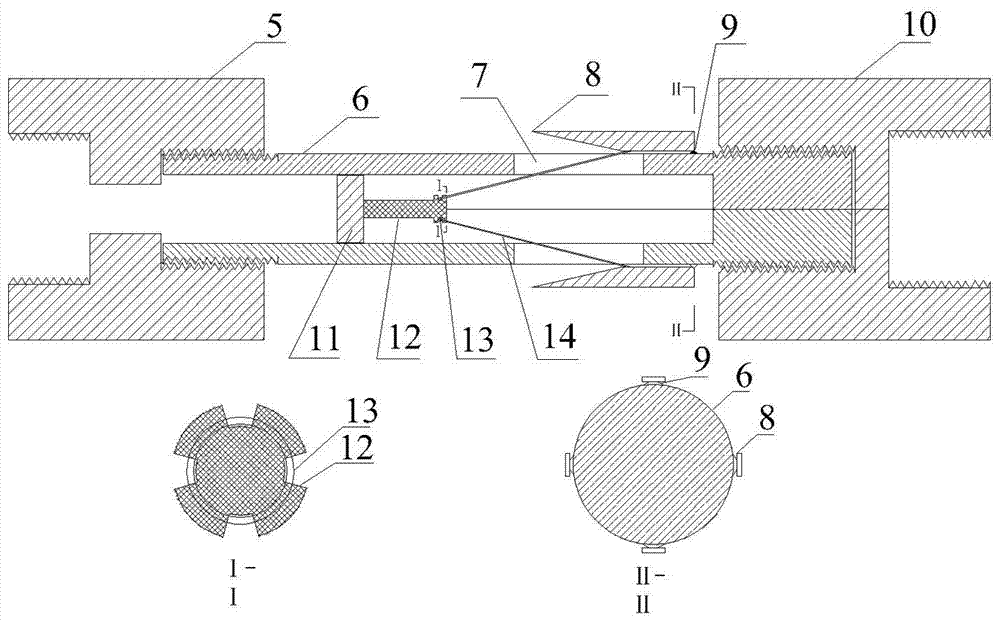

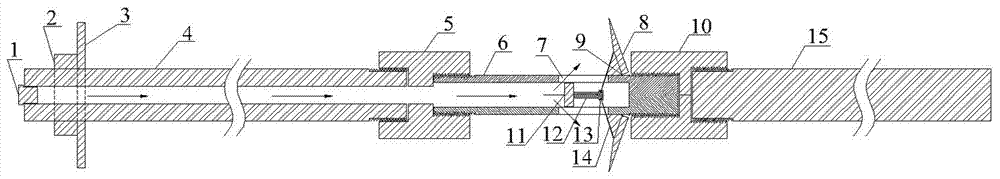

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0023] figure 1 It is a schematic diagram of the overall structure of the anchor device of the present invention, including a grouting plug 1, a nut 2, a tray 3, a grouting anchor 4, a first connecting piece 5, a cylinder body 6, an annular groove 7, a clamping wing 8, and a support 9 , The second connecting piece 10, the piston 11, the piston rod 12, the wire ring 13, the movable connecting rod 14, and the resin anchor rod 15. The first connector 5 is connected in the middle, the inner diameter is equal to the diameter of the grouting anchor 4, and the two ends are engraved with internal threads that are respectively connected with the grouting anchor 4 and the cylinder body 6, and the rotation direction of the internal threads is opposite; The middle part of the second connecting piece 10 is a solid body, and the two ends are engraved with internal threads to conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com