Ratchet wheel stop type lifting positioning conveying device

A conveying device and anti-return technology, which is applied in the field of metallurgical machinery, can solve the problems of high labor intensity and low efficiency, and achieve the effect of reducing labor intensity, reducing labor costs, and uniform and stable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

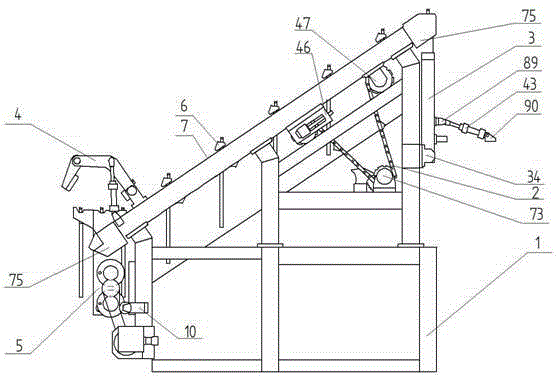

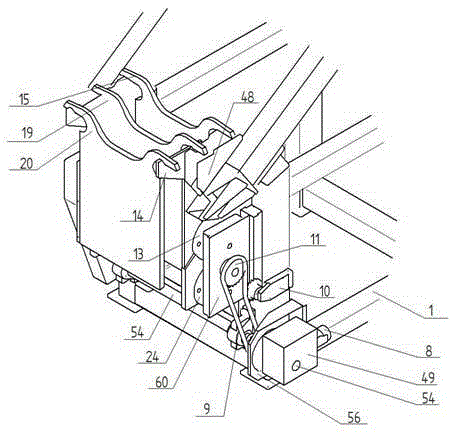

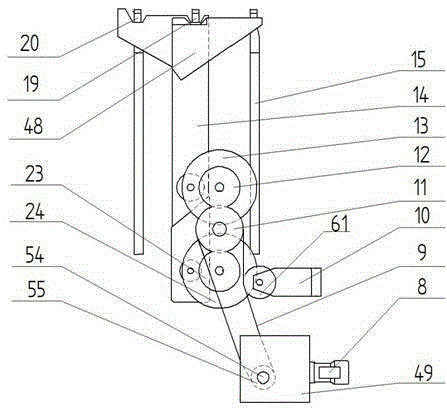

[0043] Embodiment 1: as Figure 1-18 As shown, a ratchet anti-retreat type lifting and positioning conveying device includes a lifting frame 1, a ratchet anti-retreat type lifting transmission device 2, a slice device 3, a guide baffle device 4, and a plate lifting device 5; the lifting frame 1 is installed On the ground, the ratchet anti-retreat type lifting transmission device 2 is installed on the lifting frame 1, the plate lifting device 5 is installed on the lifting frame 1 and is located at the front end of the ratchet anti-retreat type lifting transmission device 2, and the guide baffle device 4 is installed on the lifting frame 1. The plate device 5 is located at the front of the ratchet anti-retreat type lifting transmission device 2, and the slicer device 3 is installed on the lifting frame 1 at the rear of the ratchet anti-retreat type hoisting transmission device 2, and the ratchet anti-retreat type lifting transmission device 2 includes a transmission chain Ⅰ7. Te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com