An air compressor ballast semi-submersible ship ballast tank submersion auxiliary system and method

An auxiliary system and semi-submersible ship technology, applied in the direction of motor vehicles, underwater ships, special-purpose ships, etc., can solve the safety hazards of ballast water ships, insufficient suction negative pressure above, air compressor suction air path Blocking and other problems, to achieve the effect of easy water replenishment operation, good humanization and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

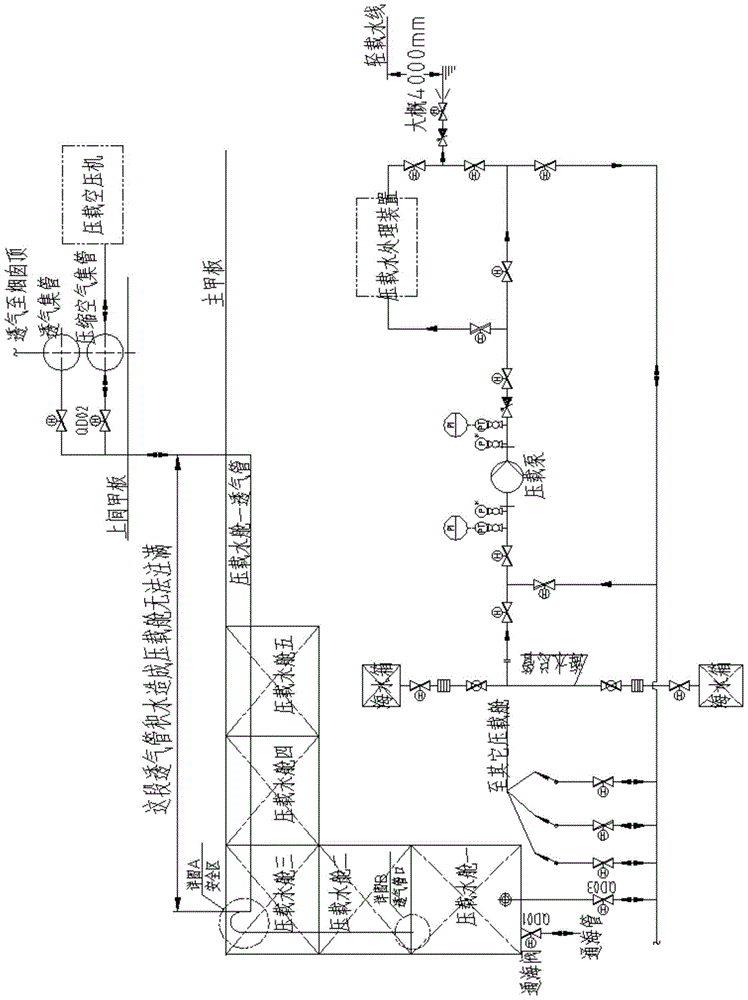

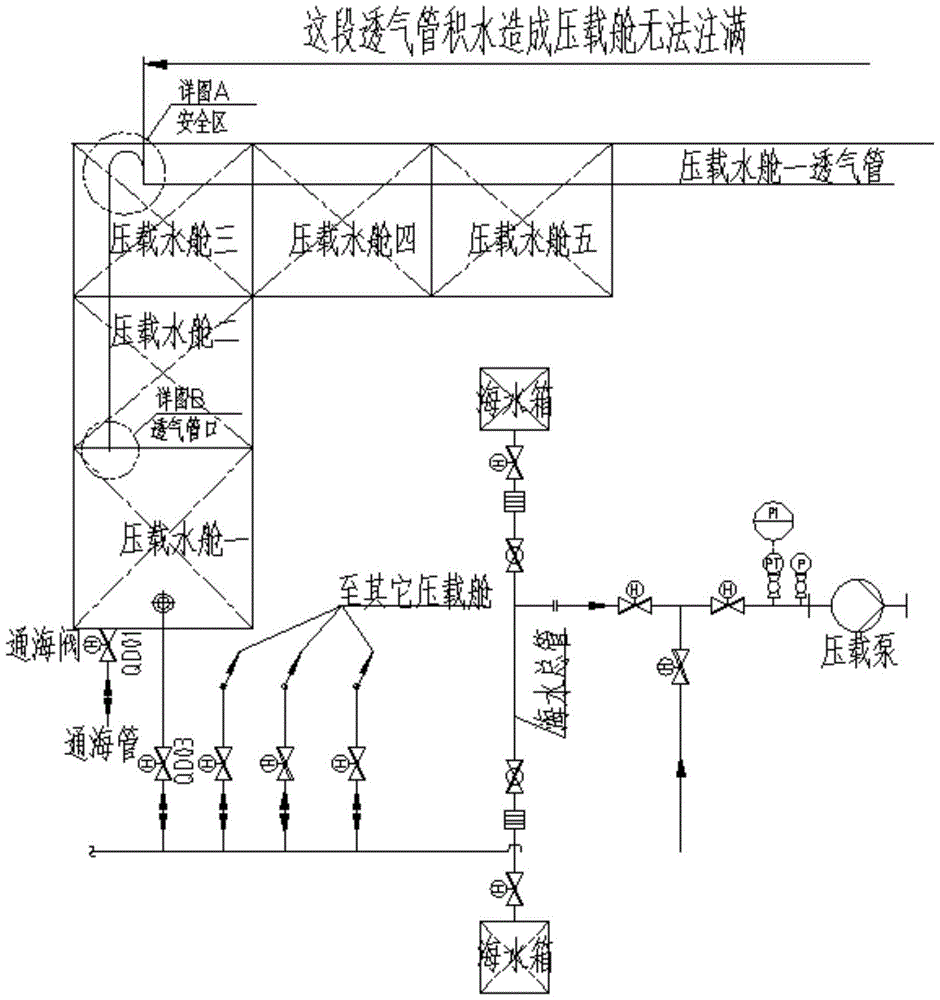

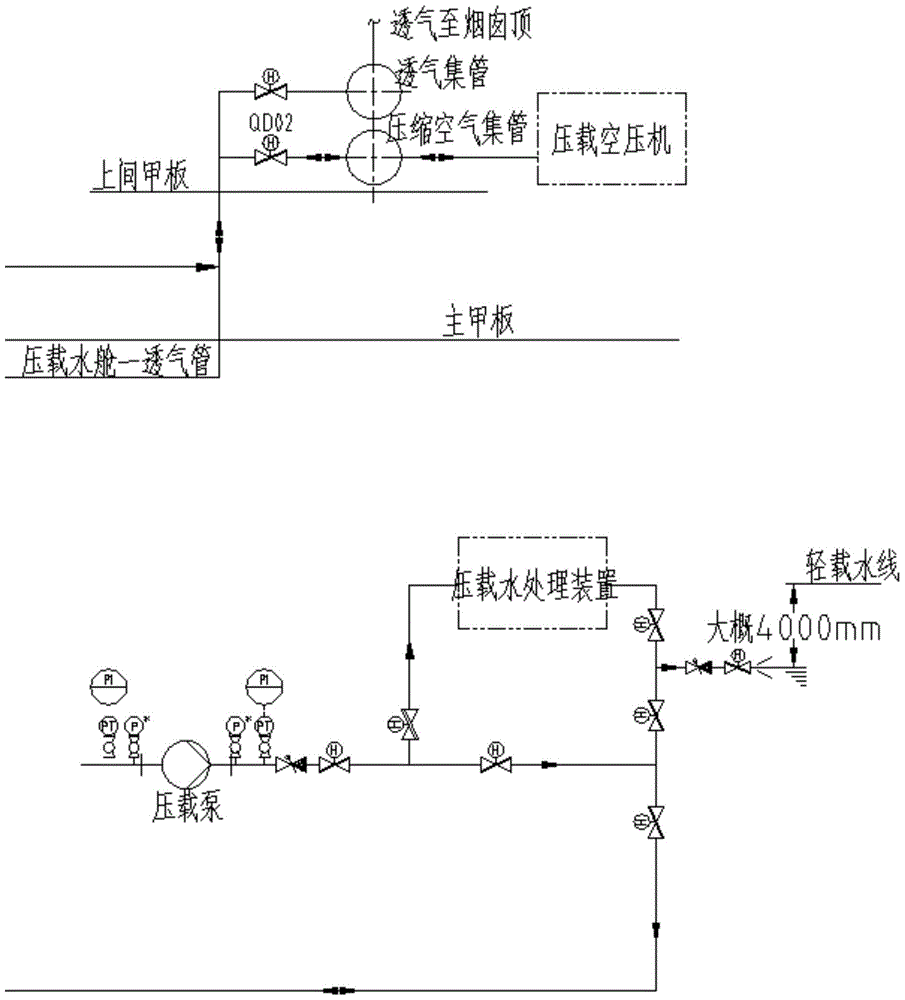

[0037] see Figure 7-Figure 9 , an air compressor ballast semi-submersible ship ballast water tank diving auxiliary system, a ballast water replenishment pump is added to the ballast water tank ballast water tank of the air compressor ballast semi-submersible ship, and the ballast water tank is ventilated The end of the pipe near the air compressor is provided with an overflow header, an overflow alarm, and an overflow tank; the water inlet end of the ballast water replenishment pump is connected to the seawater tank, and the water outlet is connected to each ballast water tank through the water replenishment regulating valve QD03 An overflow regulating valve QD04 is set in front of the overflow header, and is connected to the overflow cabin through an overflow alarm. When the overflow alarm receives an overflow signal, it will alarm, and when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com