Monorail crane centrifugal release device

A release device and centrifugal release technology, applied in transportation and packaging, railway car body parts, railway braking systems, etc., can solve the problem of affecting the service life of the spring, the inability of the slider to recover, and the large displacement of the slider and the sliding shaft. problem, to achieve the effect of stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

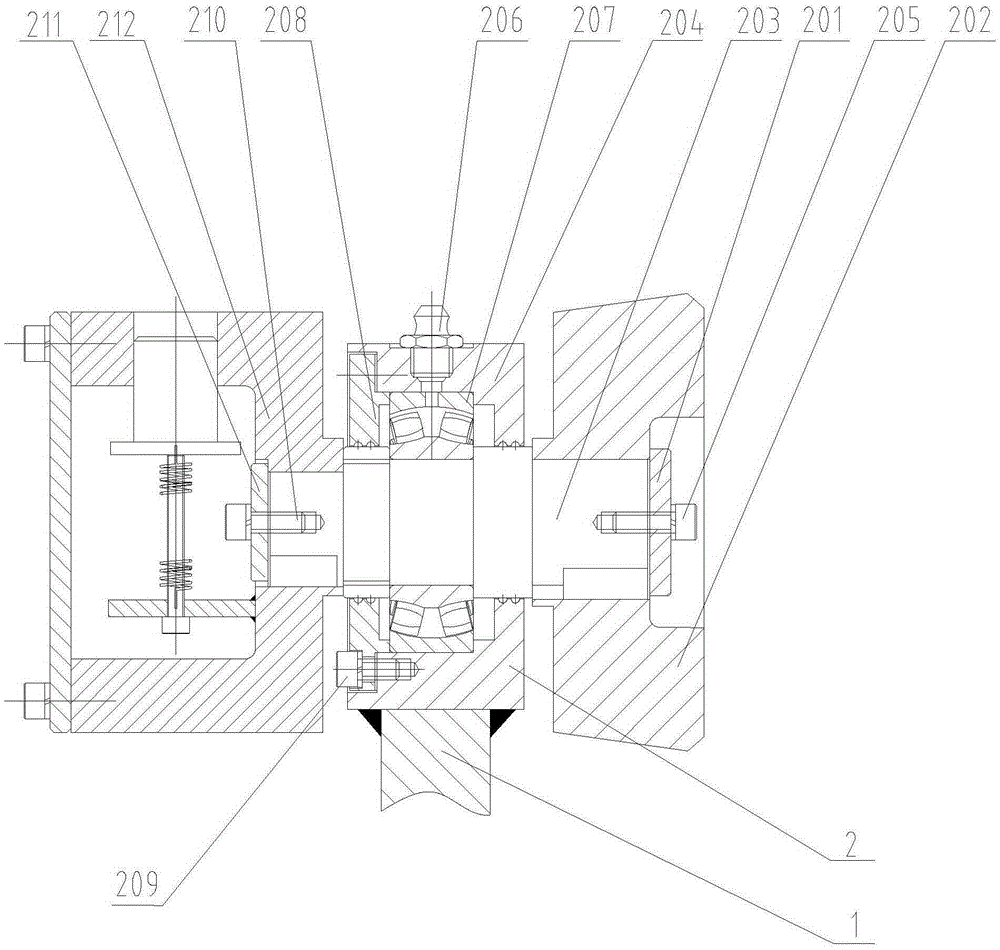

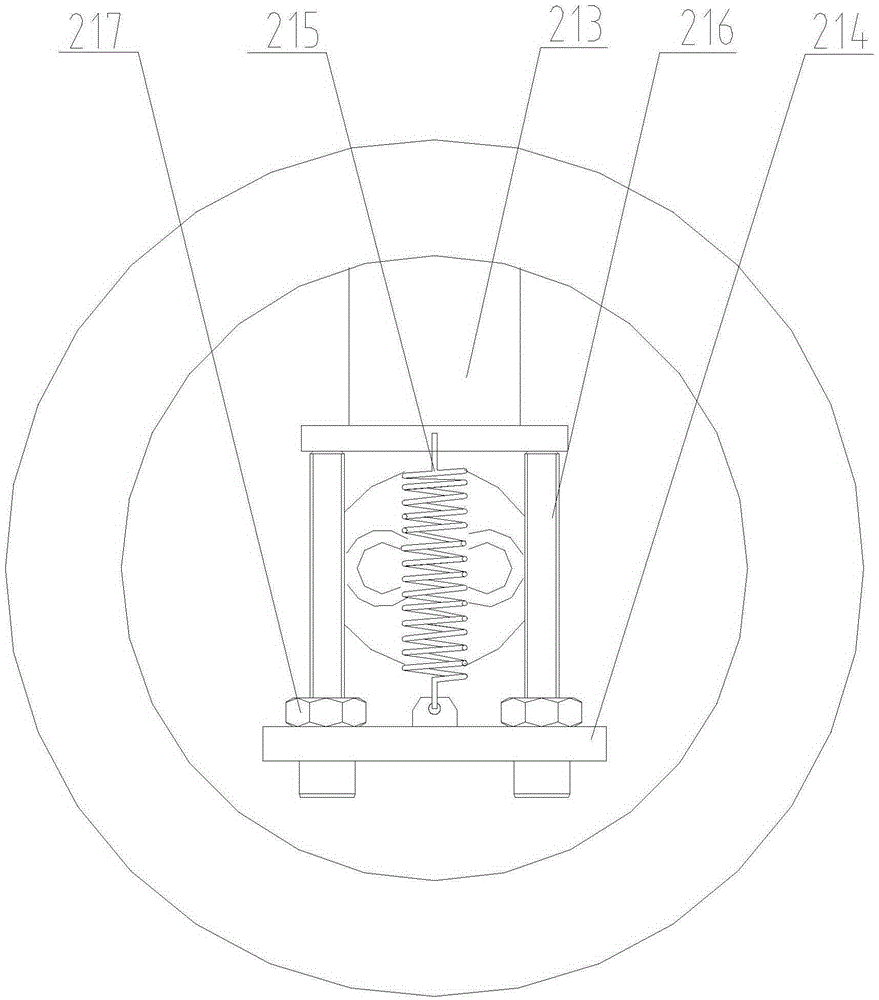

[0011] Such as figure 1 and figure 2 As shown, a monorail suspension centrifugal release device includes a brake frame 1 and a centrifugal release device 2; the centrifugal release device 2 includes a pressure plate I201, a walking wheel 202, a connecting shaft 203, a bearing seat 204, a set screw I205, Oil cup 206, bearing 207, end cover 208, end cover screw 209, set screw II210, pressure plate II211, wheel body 212, cylindrical slider 213, positioning plate 214, spring 215, hexagon socket head screw 216, hexagon nut 217; The pressing plate I201 is provided with a pair of through holes; the traveling wheel 202 is provided with a round platform and a keyway; the connecting shaft 203 is connected with the traveling wheel 202 through a key, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com