Reconfigurable automatic flexible welding production platform and operation method thereof

A technology of production platform and operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

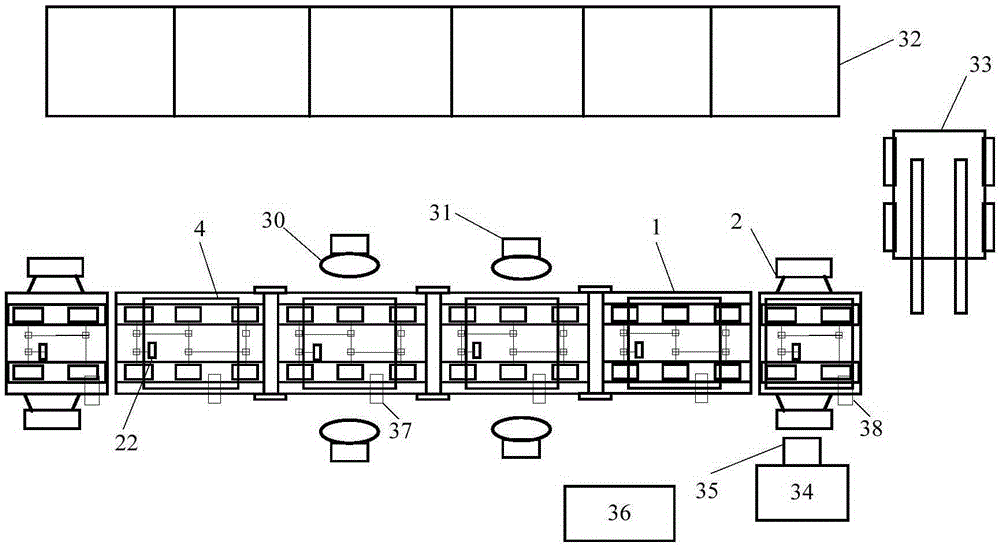

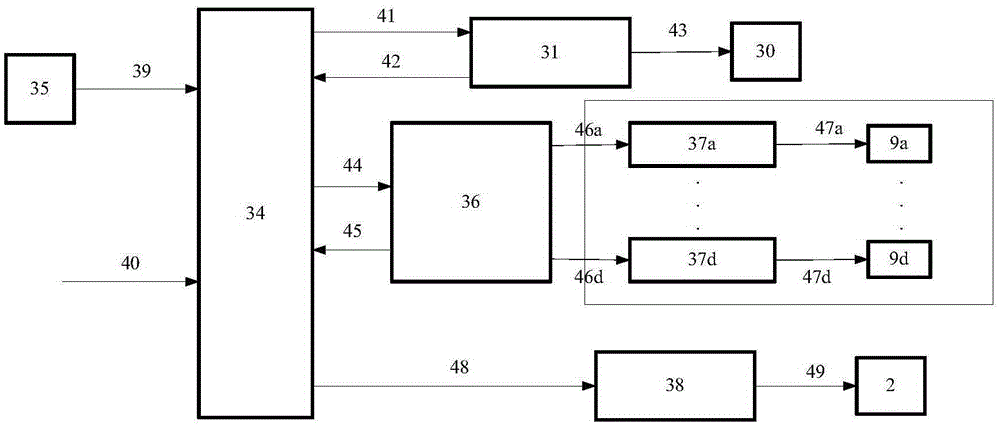

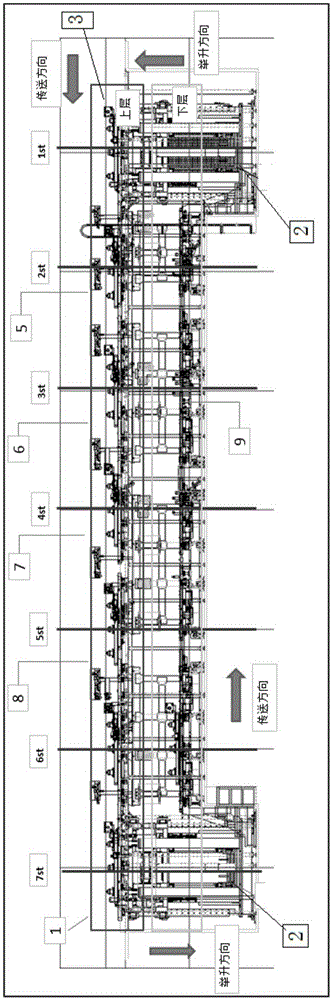

[0047] Such as figure 1 and image 3 As shown, the reconfigurable automatic flexible welding production platform includes the main body of the production line 1, the lifting mechanism 2, the transmission mechanism 3, the accompanying platform 4, the welding robot, the fixture transfer trolley, and the fixture warehouse. Wherein the accompanying platform 4 can circulate on the line body, the accompanying fixture is located on the accompanying platform 4, the lifting mechanism 2 is located at both ends of the line body, the welding robot is located on both sides of the line body welding station, and the welding robot control center controls the movement of the welding robot and The welding action of the welding torch held, the transfer trolley is responsible for the replacement of the accompanying fixture on the accompanying platform 4, the fixture warehouse stores the accompanying fixtures for the production of different types of assemblies, the production platform control cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com