A Rotary Vibrator with Adjustable Eccentric Mass

An adjustable vibration exciter technology, applied in the direction of the fluid using vibration, can solve the problems of uneven distribution of excitation energy, high purchase and maintenance costs, difficult to control the excitation amplitude, etc., and achieve easy multi-point excitation and excitation frequency range. Wide and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

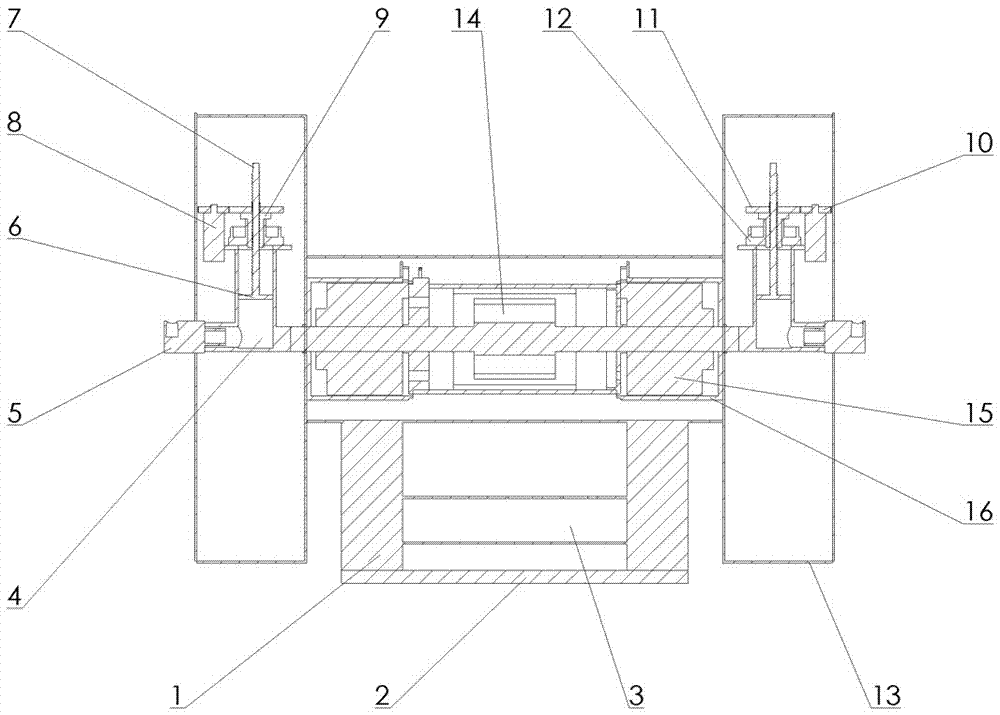

[0015] The present invention will be described below in conjunction with the accompanying drawings.

[0016] The technical idea of the present invention is: through the sleeve 4 connected with the water tank 3 as the rotating part of the vibration exciter, the movement of the piston 6 in the sleeve 4 changes the quality of the liquid in the sleeve 4, thereby adjusting the vibration.

[0017] Structure of the present invention is:

[0018] It includes a frame 1, a protective cover 13 installed on the frame 1, a water tank 3 fixed at the middle position of the bottom surface of the frame 1, a biaxial motor 14 installed on the frame 1, and a controller, wherein the biaxial The two output shaft ends of the motor 14 are equipped with a sleeve 4; a piston 6 is arranged in the sleeve 4, and a lead screw 7 is fixed on the piston 6; the lead screw 7 cooperates with the lead screw nut 9 through a thread pair; The screw nut 9 is installed on the large gear 11, and is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com