Full-automatic steam box

A fully automatic, steaming box technology, applied in the field of fully automatic steaming boxes, can solve the problems of incoordination between the entrance and exit of the box and the lifting frame inside the box, the inability to adjust the height of each floor, and the low degree of automation, so as to reduce the number of staff, The effect of reducing labor intensity and reducing labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

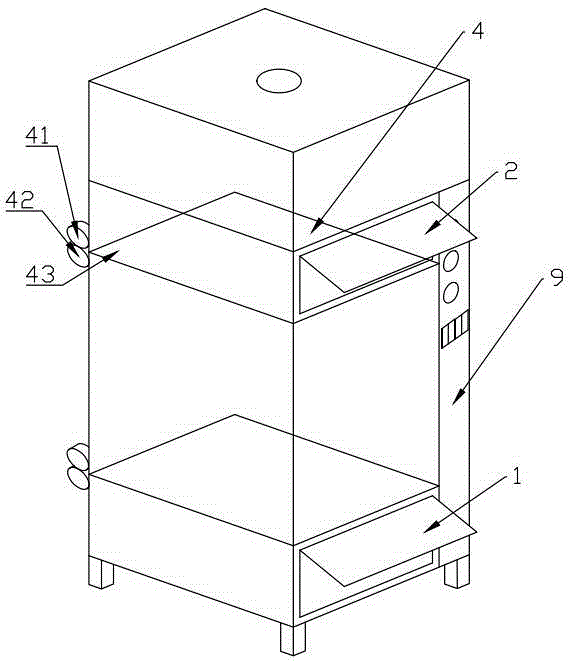

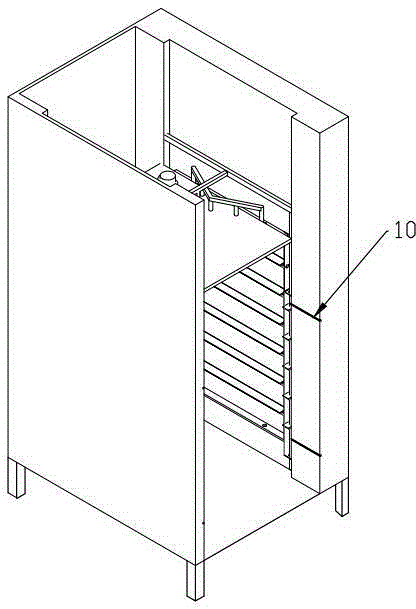

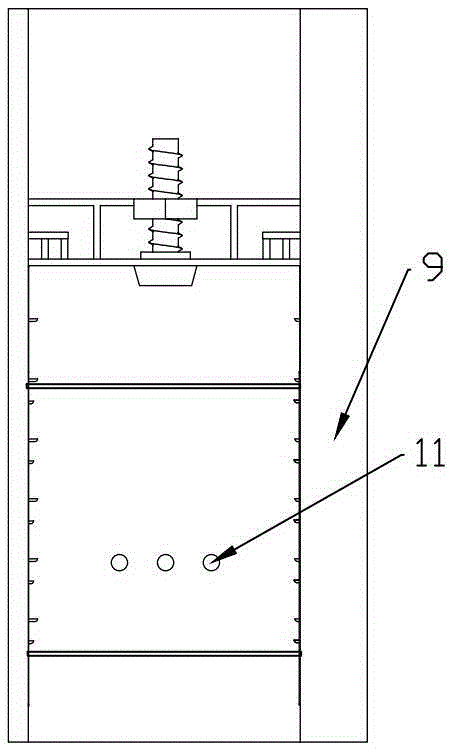

[0057] Embodiment 1: a kind of fully automatic steamer, see Figure 1 to Figure 6 , including a box body, a steam inlet and a certain number of trays are installed in the box body, an entrance door and an exit door for the tray are provided at the corresponding positions on the side of the box body, and a steam inlet and an exit door are arranged below the entrance door and above the exit door. There is a corresponding partition device 4, and also includes a lifting device 5 arranged in the box to reciprocate up and down, and a driving device 6 that drives the lifting device 5;

[0058] The lifting device 5 includes an outlet tray lifting mechanism 51, a tray lifting mechanism 52, and an inlet tray lifting mechanism 53 from top to bottom;

[0059] The entrance tray lifting mechanism 53 includes an upper lifting block that drives the tray 3 at the entrance door 1 to move upwards by 3-15 cm;

[0060] The pallet lifting mechanism 52 includes two oppositely arranged brackets 524,...

Embodiment 2

[0077] Embodiment 2: The principle of this embodiment is the same as that of Embodiment 1, the specific difference is that the outlet tray lifting mechanism 51 includes an electromagnetic block that absorbs the corresponding tray 3 to a designated position.

Embodiment 3

[0078] Embodiment 3: The principle of this embodiment is the same as that of Embodiment 1. The specific difference is that, outside the steamer, a tray support 7 is provided below the upper and lower entrances, and a roller 8 is provided at the bottom of the tray 3 . The pallet support 7 can be used as a separate part and can be selectively installed during use. Further reduce the labor intensity of workers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com