Insect transfer machine for mechanized production of royal jelly

A technology of insect transfer machine and royal jelly, which is applied in application, beekeeping, animal husbandry, etc. It can solve the problems of many operations, complicated equipment, and larvae pinching, etc., and achieves the effect of easy operation, fast speed, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

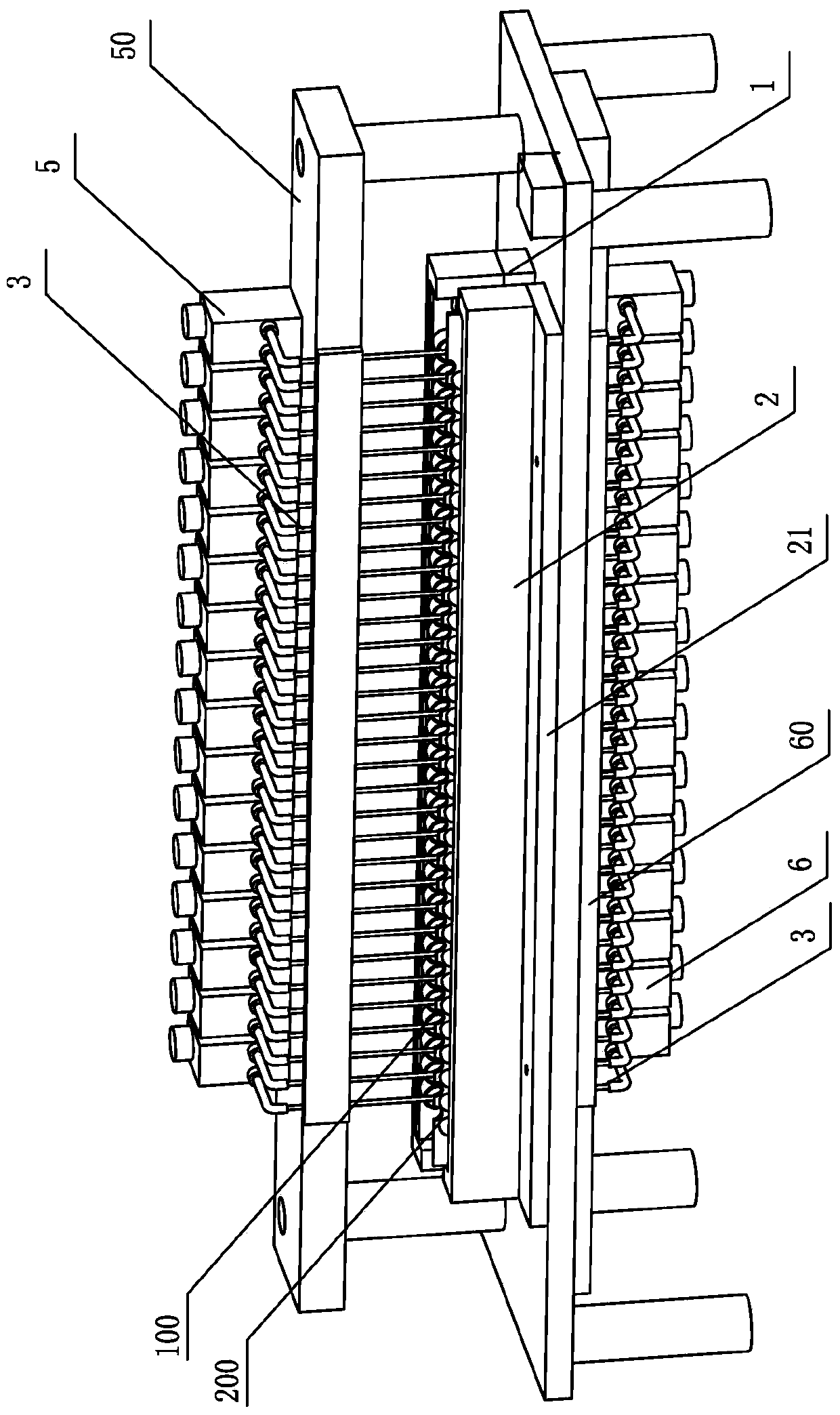

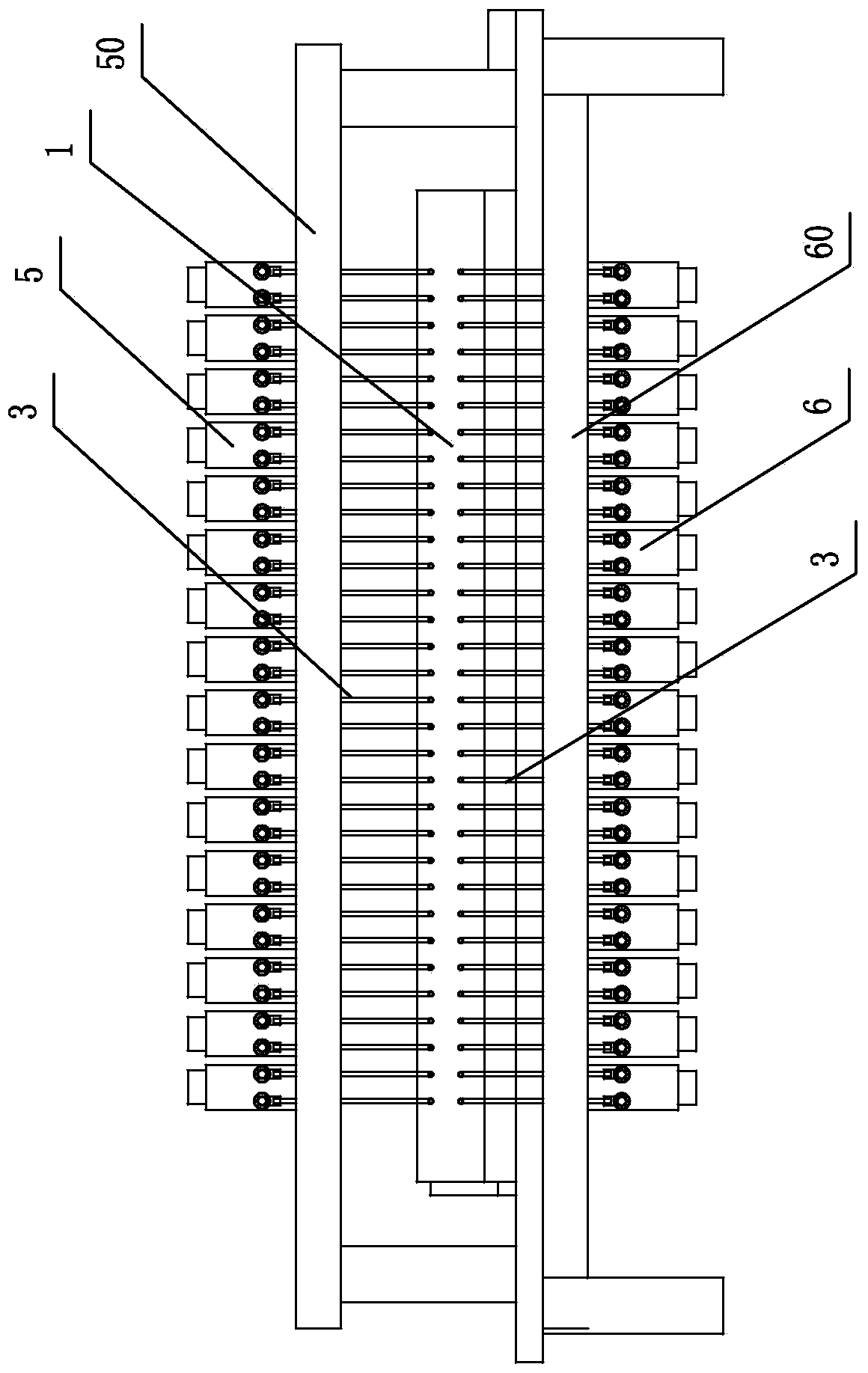

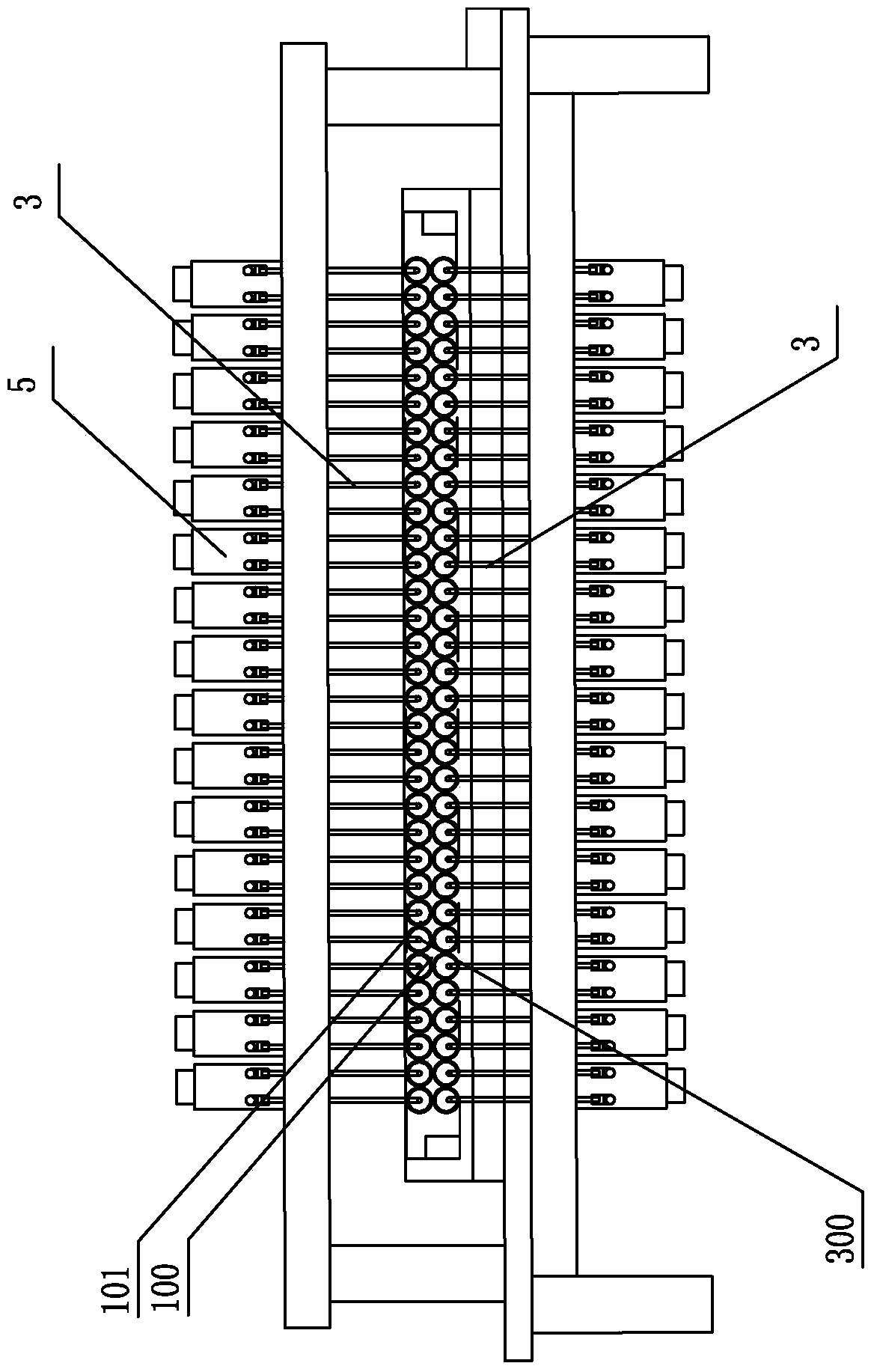

[0023] Refer to attached picture. The insect transplanting machine provided by the present invention, the insect transplanting machine includes a structure for placing the base strip and a structure for placing the sub-skin, so that the sub-skin 200 placed thereon and the platform base strip 100 can be placed face to face, and the sub-skin The nest hole 201 of laying eggs and the hole 101 on the base bar face each other.

[0024] The structure of placing the base bar is the fixed table 1 in the middle of the insect transfer machine frame, on which the positioning structure of the base bar 100 can be set, so that when the base bar 100 is placed on the fixed table 1, the position can be stable.

[0025] The structure for placing the sub-skin is a mobile platform 2, which can be slidably arranged on the support structure 21 at the middle part of the frame of the insect transfer machine. The positioning structure enables the sub-skin 200 to be in a stable position after being pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com