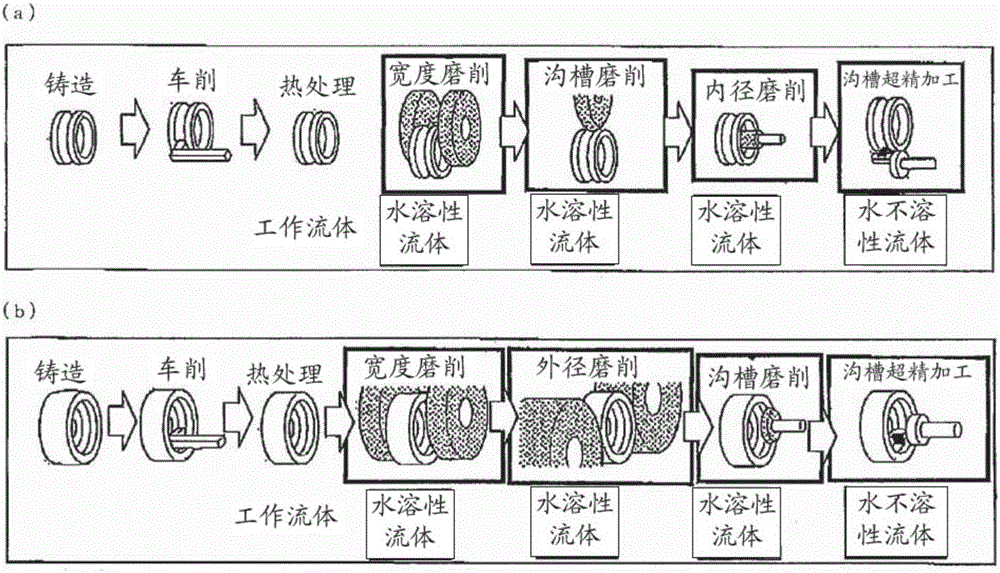

Water-soluble cutting/grinding fluid

A water-soluble, grinding fluid technology, applied in the field of water-soluble cutting or grinding fluid, can solve problems such as insufficient, achieve excellent diffusivity, reduce processing costs, and simplify equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0091] The present invention is described below with reference to examples, but the present invention should not be construed as being limited to these examples.

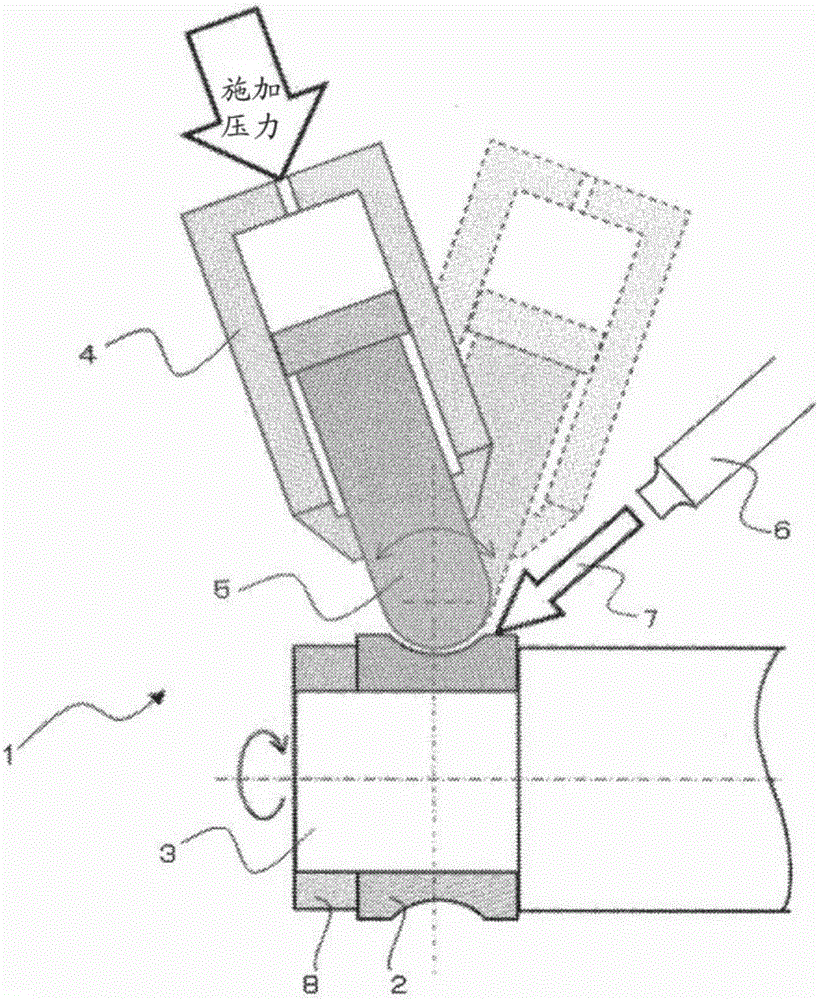

[0092] The various components were mixed in the ratios shown in Table 1 to prepare water-soluble cutting or grinding fluids of Examples and Comparative Examples. Fluid properties were evaluated for cutting or grinding fluids in terms of contact angle, coefficient of friction, dispersion and chipping tests, and machining performance was evaluated using a superfinishing test setup. Table 1 shows the results.

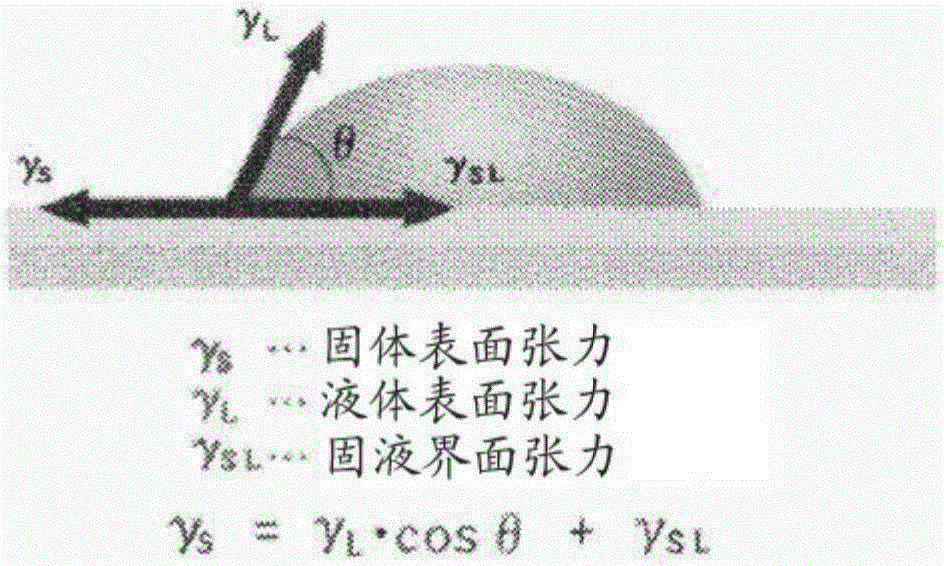

[0093] (1) Measurement of contact angle (wettability evaluation)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com