High-pressure oil, gas, water and solid four-phase separating and metering device for wellhead of skid-mounted oil and gas field

A metering device, high-pressure oil technology, applied in the direction of measurement, wellbore/well components, production fluid, etc., can solve the problems of high cost of separation equipment, cumbersome installation of resources, waste of environment, etc., to save equipment costs, reduce use costs, Effect of reducing gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

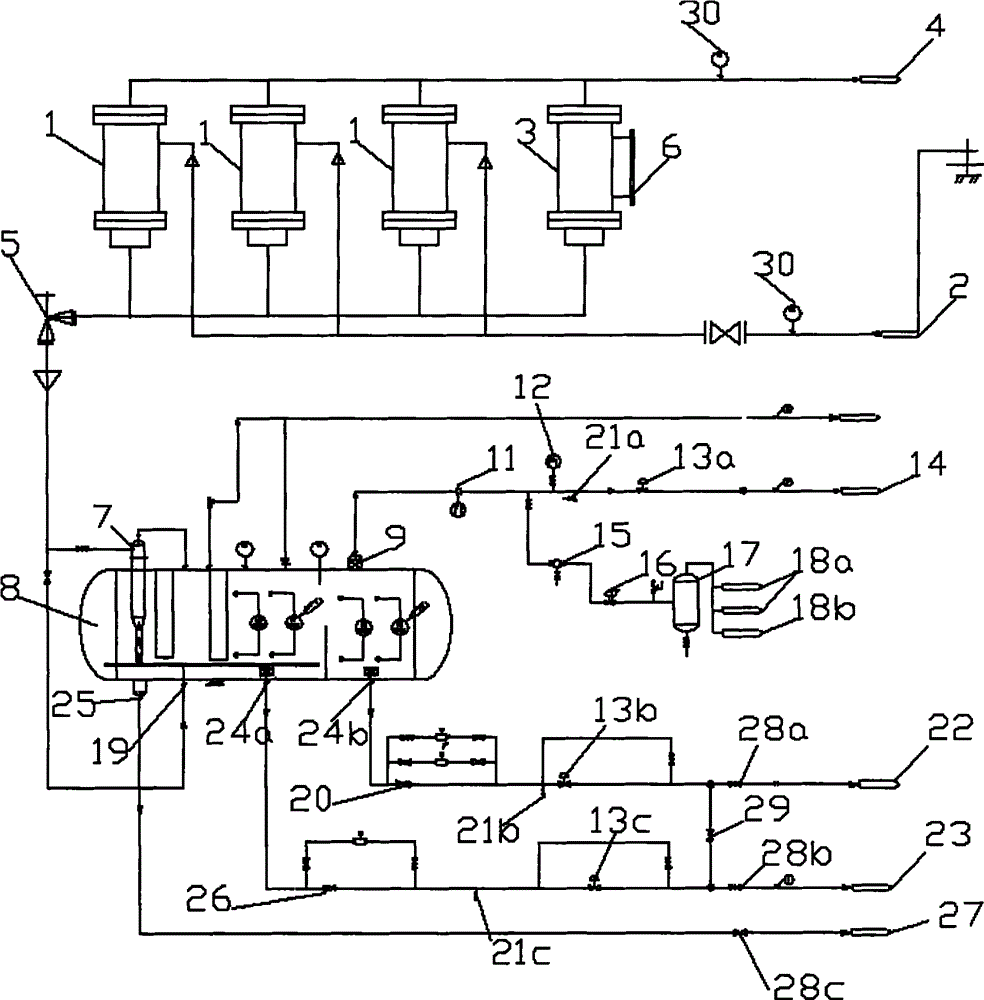

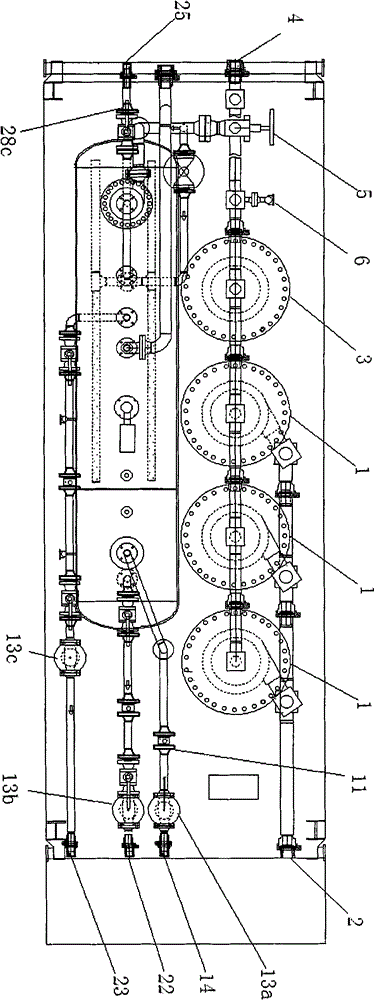

[0018] As shown in the figure, a skid-mounted oil and gas field wellhead high-pressure oil, gas, water, and solid four-phase separation metering device is composed of a high-pressure gas separation module and a low-pressure gas, oil, water, and solid separation module. The high-pressure gas separation module The liquid mixed with oil, gas, water, and solid particles is input through the high-pressure inlet 2, and the liquid is connected to the input end of the high-pressure cyclone separator 1 composed of one or more parallel connections through a pipeline with a valve for high-pressure gas separation. The natural gas output end of the high-pressure cyclone separator 1 and the liquid and solid particle mixing output port are connected in parallel with the high-pressure liquid level balance tank 3 through pipelines, wherein the natural gas output end transmits the high-pressure gas to the high-pressure gas outlet 4 through the high-pressure gas output pipeline , the liquid and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com