Seafloor sediment coring device applicable to seafloor drilling machine

A seabed sediment and coring device technology, which is applied in the direction of extraction of undisturbed cores, earthwork drilling, etc., can solve the problems of low coring rate, influence on integrity, damage, etc., and achieves high coring rate, simple and reliable structure. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

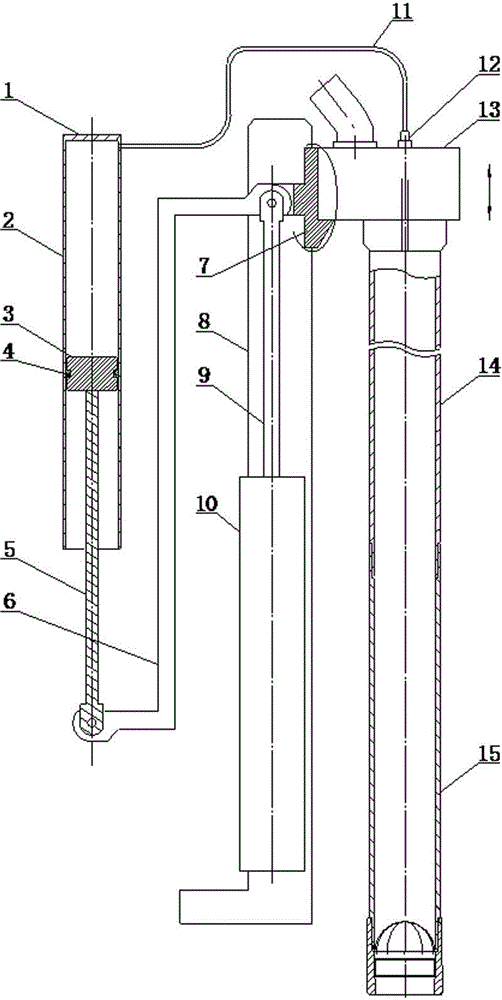

Examples

Embodiment 2

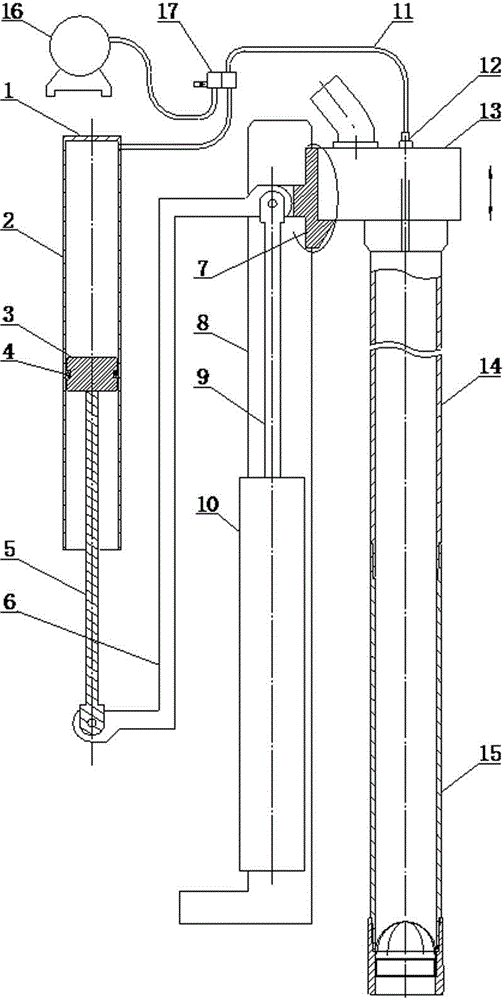

[0017] Such as figure 2 As shown, the structure is similar to that of Embodiment 1, except that the water supply pipe 11 is not directly connected to the suction piston cylinder 1 , but is connected to the suction piston cylinder 1 through a switching valve 17 . The other port of the transfer switch valve 17 is connected with the flushing water pump 16 of the subsea drilling rig. The function of the transfer switch valve 17 is to switch the connection between the water supply pipe 11 and the suction piston cylinder 1 and the flushing water pump 16. When the water supply pipe 11 passes through the transfer switch valve When 17 is connected with the suction piston cylinder 1, realize that sediment is pressed into the suction coring; when the water supply pipe 11 is connected with the flushing water pump 16 through the changeover switch valve 17, realize the common positive circulation flushing, rotary drilling and coring.

Embodiment 3

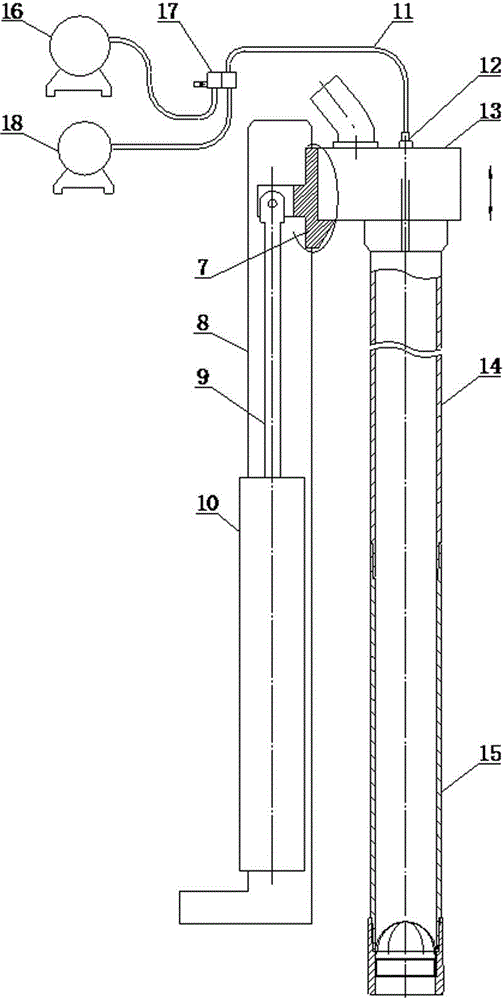

[0019] Such as image 3 As shown, the structure is similar to that of Embodiment 2, the difference is that the suction piston cylinder 1 can be replaced by a water pump 18, when the drilling power head 13 pushes the core drilling tool 15 to press into the sediment for coring operation , Utilize the water pump 18 to draw water from the drill pipe 14 and the core drilling tool 15 through the water supply pipe 11 . In order to minimize the disturbance to the coring sample, the size of the water pump 18 should be reasonably selected, and at the same time, the start-stop time and the pumping volume of the water pump 18 should be reasonably controlled, so that the water volume drawn by the water pump 18 from the inner cavity of the drill pipe 14 and the core drilling tool 15 is the same as the The amount of sediment entering the core drilling tool 15 and draining into the inner cavity of the drill pipe 14 is substantially equal.

Embodiment 4

[0021] Such as Figure 4 As shown, the structure is similar to that of Embodiment 1, except that the core drilling tool 15 is an advanced double-tube drilling tool, and the core tube assembly 21 commonly used by existing seabed drilling rigs is suspended in the core drilling tool 15 and Extend the center hole of the core drilling tool 15 for a certain distance, and one or more seal grooves 19 are provided in the center hole of the drill bit of the core drill tool 15, and a seal ring 20 is placed in the seal groove, and the core tube assembly 21 is provided with a sealing ring 20. The sealing ring 20 is used to seal between the pipe and the core drilling tool 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com