String Rotary Running Tool

A technology of tools and pipe strings, which is applied in the field of tooling to assist pipe strings to run in, can solve the problems of increasing operation time, reducing operation timeliness, and increasing operation costs, and achieves the effects of reducing weight loss, reducing friction and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

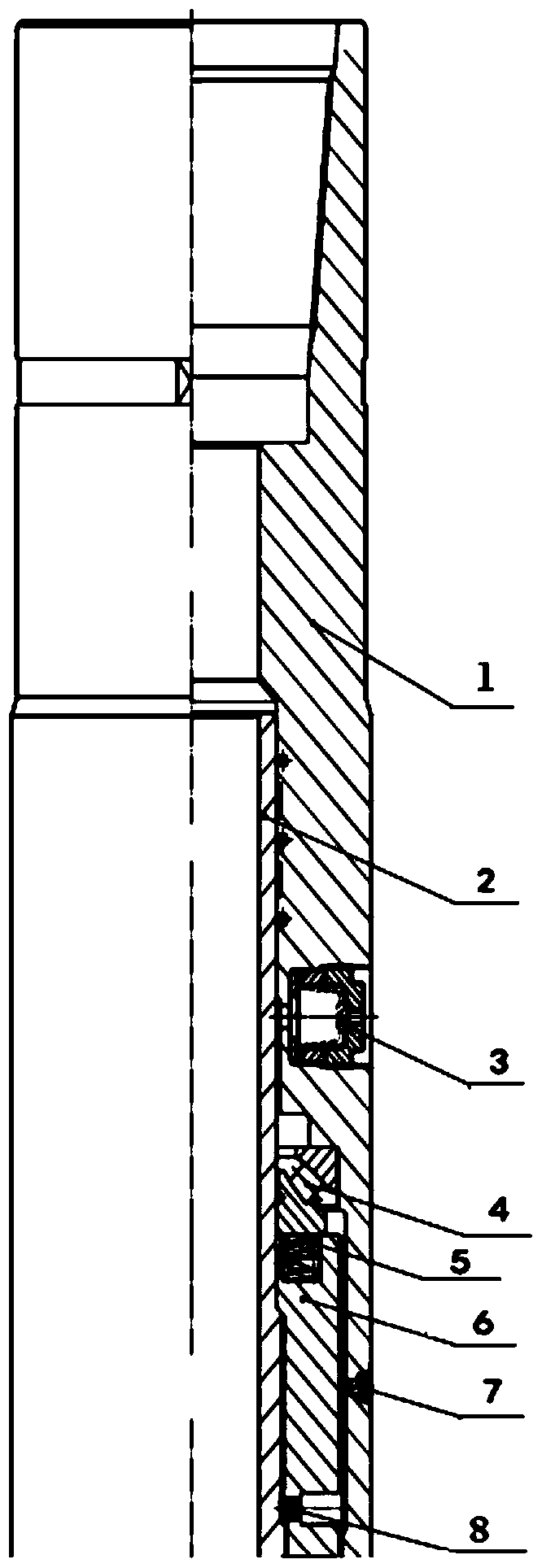

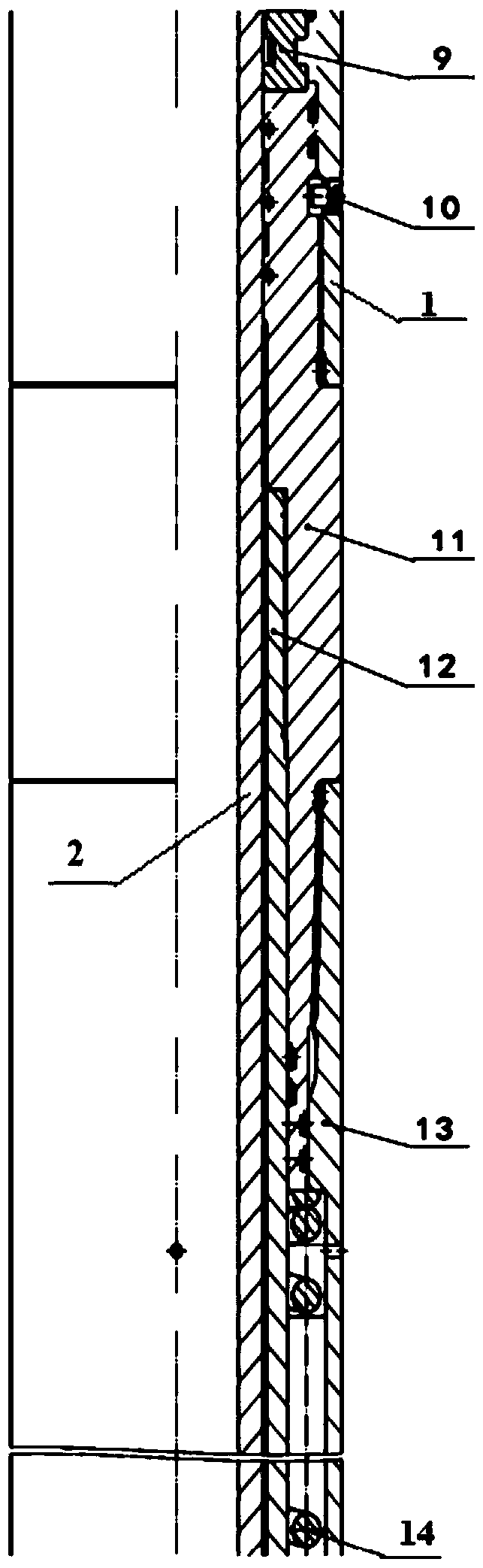

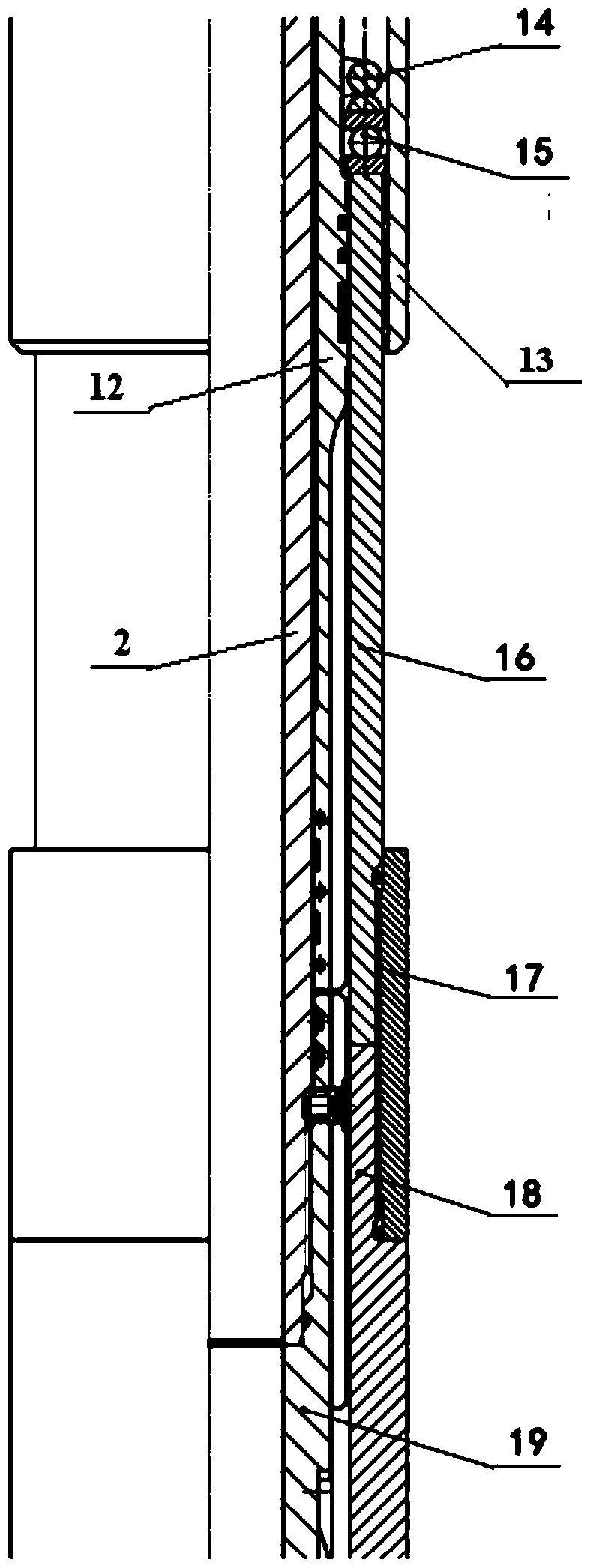

[0028] Such as Picture 1-1 , 1-2 , 1-3, 1-4, and 1-5 are connected in series in sequence to obtain the complete structure of the present invention.

[0029] The pipe string rotary running tool of the present invention includes an upper joint 1 with internal threads at the upper and lower ends. The internal thread buckle at the upper end of the upper joint 1 can be HT55. To the through hole, an oil bag 3 and an oil plug 7 are arranged through threads respectively in the through hole. The lower end of the upper joint 1 is threadedly connected with a connecting body 11, and is fixed by anti-retraction screws 10. The outside of the lower end of the connecting body 11 is threaded with a spring barrel 13, and the inner side is threaded with a flower with an axial keyway on the outside of the lower end. Key shaft 12 (such as figure 2 and image 3 As shown), the spring b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com