Device for limiting distortional buckling of I-shaped steel beam

An I-shaped, steel beam technology, applied in joists, girders, truss beams, etc., can solve problems such as affecting the use of building space, use of materials, and inconvenient construction, so as to reduce on-site construction costs, save building materials, The effect of reducing the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

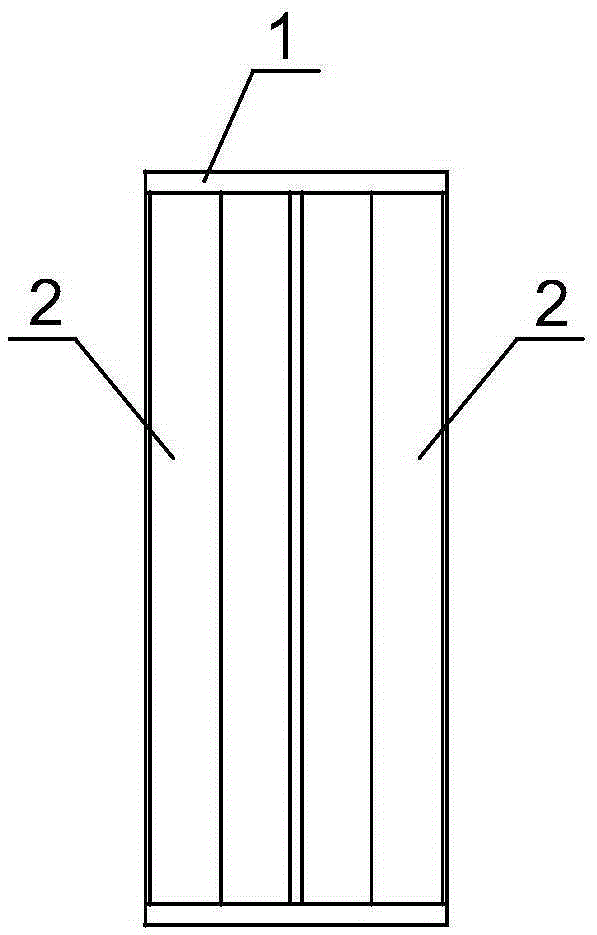

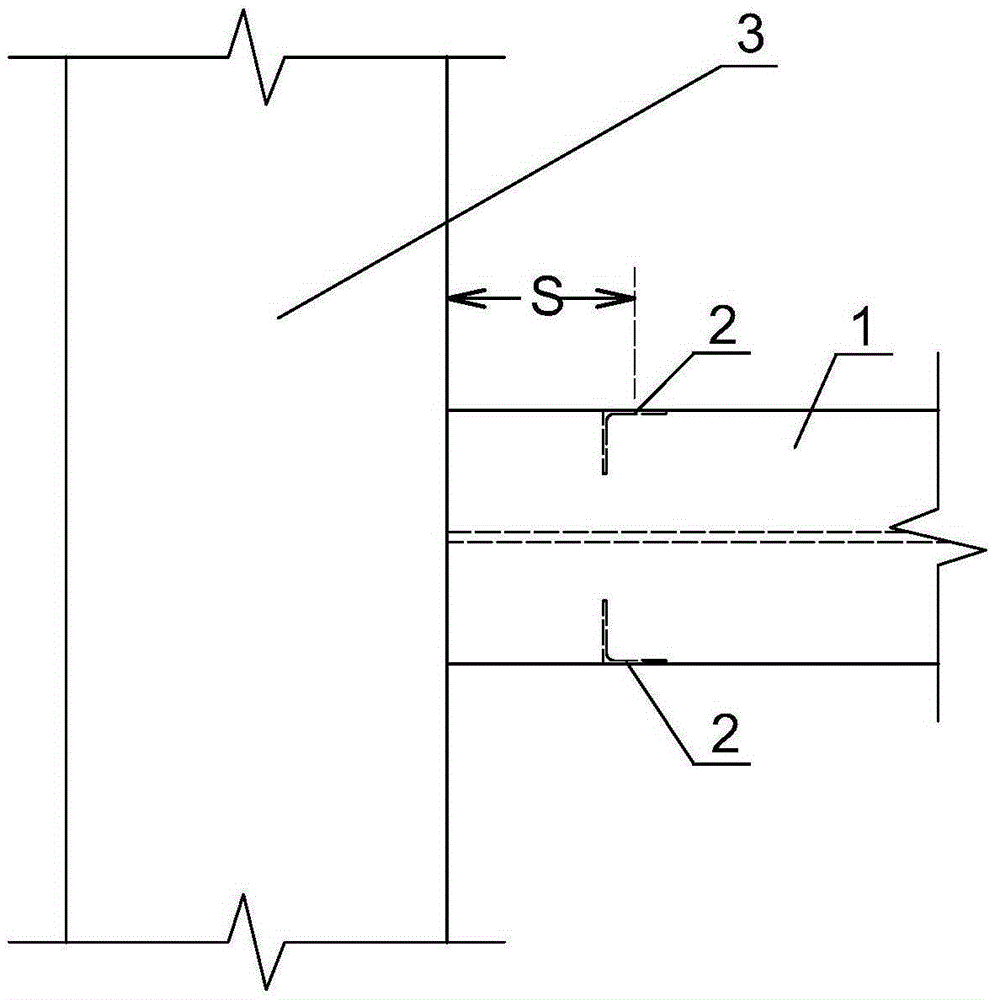

[0014] A device for restricting the distortion and buckling of an I-shaped steel beam. On both sides of the web plate of the I-shaped steel beam 1, an angle steel 2 with an L-shaped cross-section having two limbs is respectively arranged. The upper end and the lower end of the angle steel are respectively connected to the The upper flange and the lower flange of the I-shaped steel beam are welded, one branch of the angle steel is parallel to the web of the I-shaped steel beam, and the branch parallel to the web of the I-shaped steel beam is connected to the I-shaped steel beam The upper and lower flanges are flush, and the distance between the angle steel and the frame column 3 can also be that the distance S from the wall is 0.15 times the span of the steel beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com