A kind of preparation method of inverse emulsion dust suppressant

A technology of reverse emulsion and dust suppressant, which is applied in the field of preparation of reverse emulsion dust suppressant, can solve problems such as water and soil pollution, dust prevention, and easy reduction of dust suppression effect, and achieve low wind erosion rate, strong anti-loss performance, Conducive to the dust-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

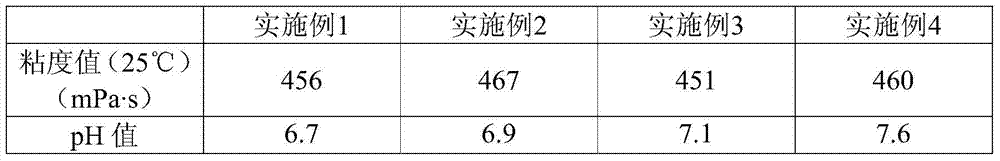

Examples

Embodiment 1

[0026] A preparation method of an inverse emulsion dust suppressant, comprising the following steps:

[0027] 1) Add 700 parts of deionized water and 50 parts of pure acrylic acid (AA) to reactor 1, and adjust the pH to 6.5 with 35% sodium hydroxide. During this period, an ice-water bath is used to control the water temperature not to exceed 20° C. to obtain a water-phase monomer solution.

[0028] 2) Add 83.5 parts of 10# white oil to reactor 2, 20.5 parts of polyoxyethylene oleate and 41.5 parts of diethylene glycol monolaurate are compounded as emulsifier (the total amount of emulsifier accounts for the total weight of solvent 6.5%), dissolved into an oil phase. The oil phase solution and the water phase solution in step 1) were mixed, then circulated and homogenized by a high-shear force homogenizing pump, emulsified for 30 minutes, and a uniform and stable monomer emulsion with an oil-water ratio of 1:5.7 was obtained.

[0029] 3) The monomer emulsion is placed in the r...

Embodiment 2

[0032] A preparation method of an inverse emulsion dust suppressant, comprising the following steps:

[0033] 1) Add 700 parts of deionized water and 50 parts of pure acrylic acid (AA) to reactor 1, and adjust the pH to 6.65 with 35% sodium hydroxide. During this period, an ice-water bath is used to control the water temperature not to exceed 20° C. to obtain a water-phase monomer solution.

[0034] 2) Add 80 parts of 260# solvent naphtha in reactor 2, 23 parts of polyoxyethylene oleate and 25 parts of diethylene glycol monolaurate are compounded as emulsifier (the total amount of emulsifier accounts for the total weight of solvent 6%), dissolved into an oil phase. Mix the oil phase solution with the water phase solution in step 1) and circulate through a high-shear force homogenizing pump to homogenize and emulsify for 30 minutes to obtain a uniform and stable monomer emulsion with an oil-water ratio of 1:6.

[0035] 3) The monomer emulsion is placed in the reaction kettle ...

Embodiment 3

[0038] A preparation method of an inverse emulsion dust suppressant, comprising the following steps:

[0039] 1) Add 700 parts of deionized water and 50 parts of pure acrylic acid (AA) to reactor 1, and adjust the pH to 7 with 35% sodium hydroxide. During this period, an ice-water bath is used to control the water temperature not to exceed 20° C. to obtain a water-phase monomer solution.

[0040]2) Add 81 parts of 280# solvent naphtha in reactor 2, 24 parts of polyoxyethylene oleate and 29 parts of diethylene glycol monolaurate are compounded as emulsifier (the total amount of emulsifier accounts for the total weight of solvent 5.5%), dissolved into an oil phase. Mix the oil phase solution with the water phase solution in step 1), and then pass through a high-shear force homogenization pump to homogenize and emulsify for 30 minutes to obtain a uniform and stable monomer emulsion with an oil-water ratio of 1:6.2.

[0041] 3) The monomer emulsion is placed in the reaction kett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com