Rope winding preventing elevator

An anti-winding and rope technology, which is applied to elevators, hoists, transportation and packaging in buildings, etc., can solve the problems of rope winding and knotting, rope falling off, affecting elevator lifting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0018] The invention will be described in detail below with reference to the accompanying drawings and examples.

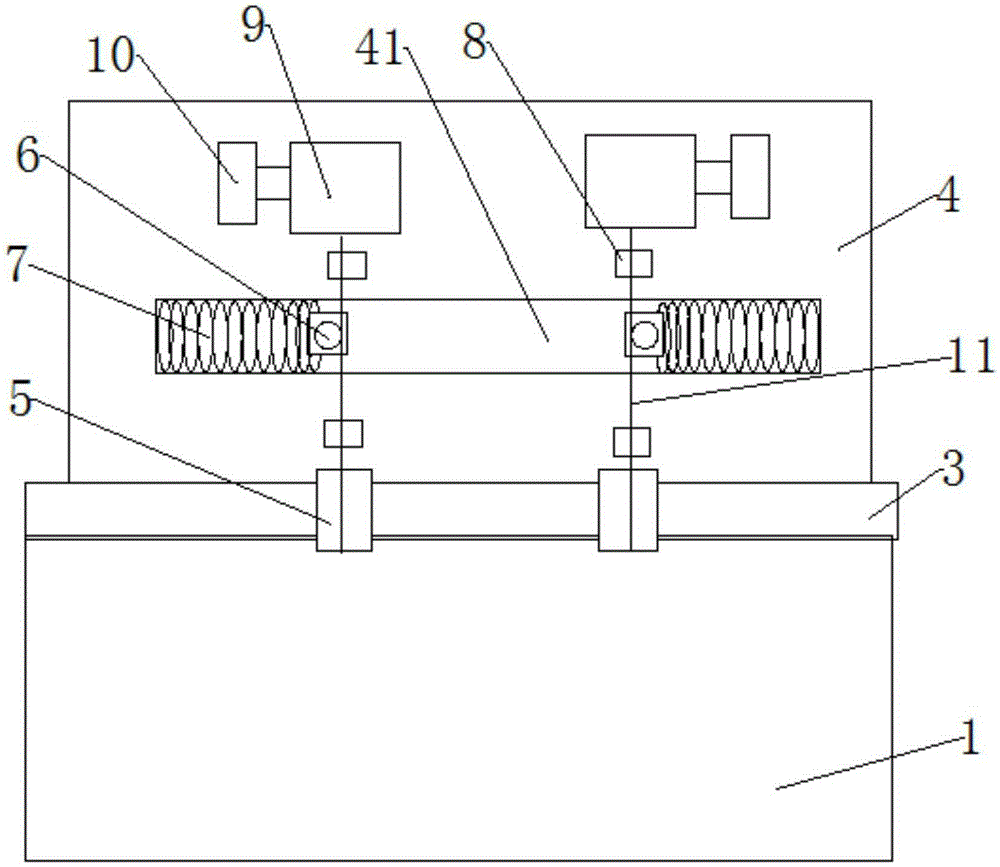

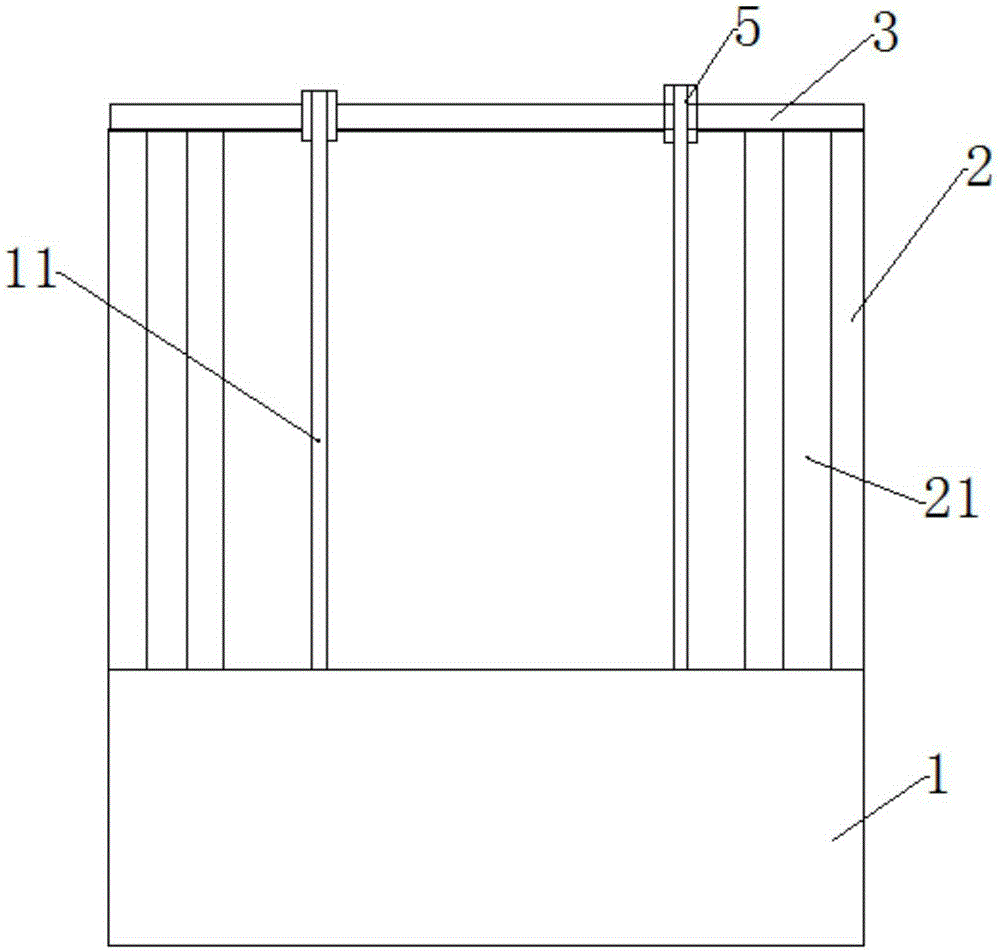

[0019] Such as figure 1 with 2 As shown, the present invention includes a lifting box 1, a lifting slide rail 2, a rope 11, a support shaft 3, a support plate 4, a roller 5, a sliding frame 6, a compression spring 7, a limit ring 8, a winding sheave 9, and a motor 10 and controller;

[0020] The lifting box 1 can be slidably installed in the chute 21 on the front side of the lifting slide rail 2, the support shaft 3 is vertically fixed on the top of the lifting slide rail 2, and there are at least two rollers 5. The central axis is symmetrically installed on the support shaft 3;

[0021] The support plate 4 is vertically fixed on the rear side of the upper end of the lifting slide rail 2. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com