Multi-cell-thin-wall energy absorbing structure and application structure thereof

A technology for energy-absorbing structures and applied structures, which can be applied to substructures, bumpers, transportation and packaging, etc., and can solve unsatisfactory energy-absorbing structures, small collision energy-absorbing space and lightweight design requirements, and single-cell thin-walled energy-absorbing structures Difficult to meet the design requirements of electric vehicles and other issues, to achieve good collision safety performance, low manufacturing cost, and reduced quality

Active Publication Date: 2016-01-13

HUNAN UNIV

View PDF9 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

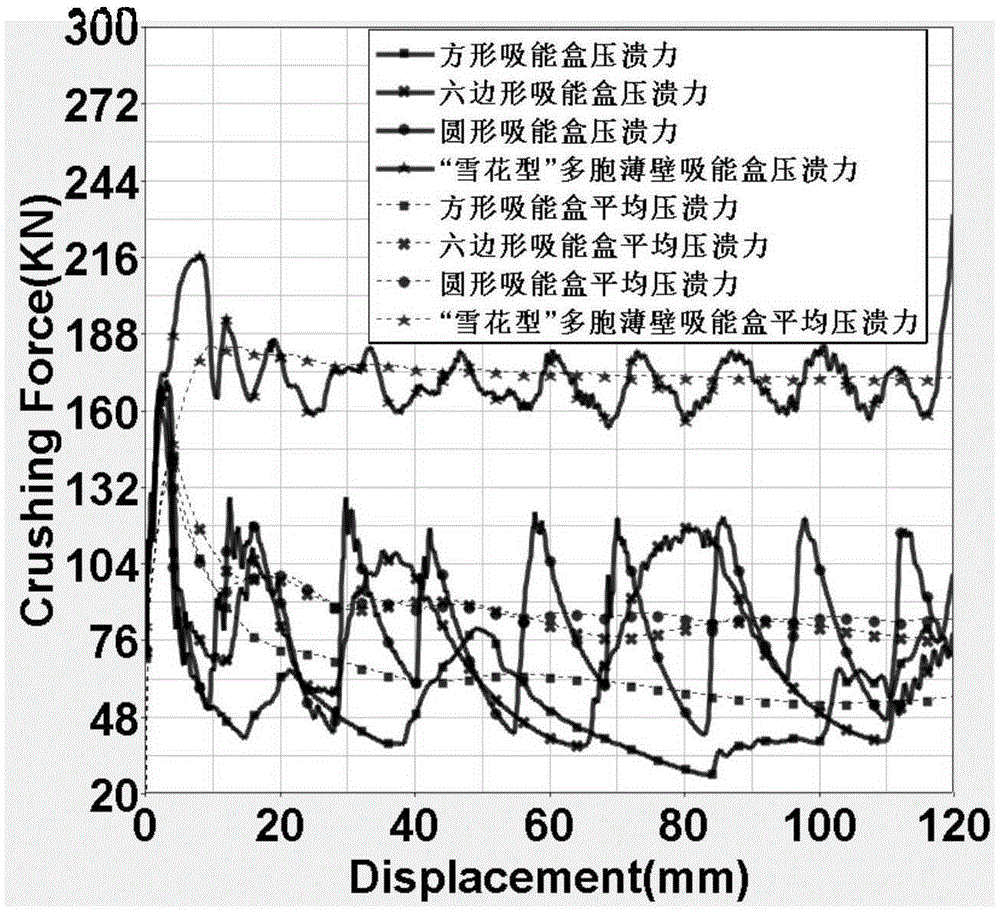

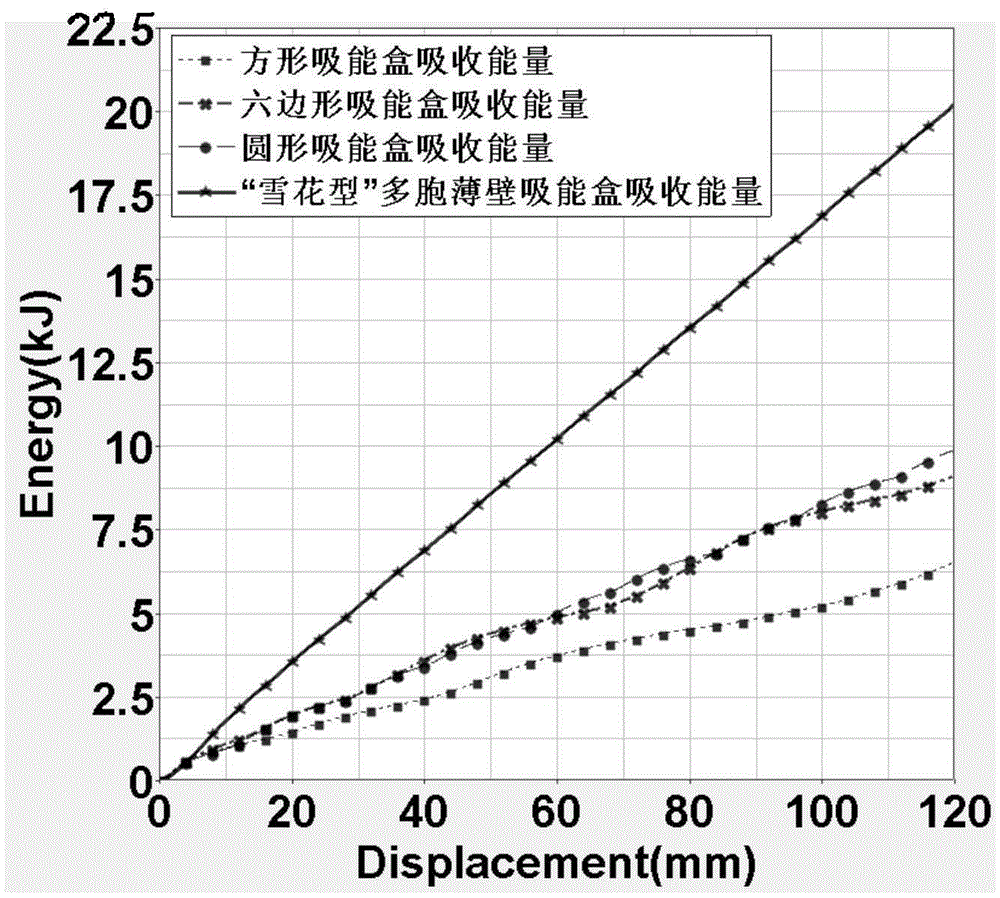

[0003] In the traditional design of unit-cell thin-walled energy-absorbing structures, unit-cell square energy-absorbing structures, circular energy-absorbing structures, hat-shaped energy-absorbing structures or polygonal energy-absorbing structures are widely used by major automobile manufacturers, but the traditional The energy-absorbing structure cannot satisfactorily coordinate the contradiction between the energy-absorbing structure's high specific

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a multi-cell-thin-wall energy absorbing structure and an application structure thereof. The multi-cell-thin-wall energy absorbing structure comprises an outer layer thin-wall energy absorbing structure and an inner layer thin-wall energy absorbing structure. The center line of a hollow small regular prism arranged in the inner layer thin-wall energy absorbing structure in a sleeved mode and the center line of a hollow large regular prism arranged in the inner layer thin-wall energy absorbing structure in a sleeved mode coincide with each other; a first connection rib plate and a second connection rib plate are connected between the middle positions of corresponding edges of the small regular prism and the large regular prism and corresponding corners. Two steel plates of the outer layer thin-wall energy absorbing structure are parallel to two edges of the corresponding edge corner of the inner layer thin-wall energy absorbing structure, and the included angle between the steel plates is the same as the degree number of the corresponding edge corners; one end of a third connection rib plate is connected with the two steel plates, the other end of the third connection rib plate is connected to the outside of the edge of the large regular prism; one end of a fourth connection rib plate is connected to the included angle of the steel plates, and the other end of the fourth rib plate is connected to the outer side of the edge corner of the large regular prism. The multi-cell-thin-wall energy absorbing structure can coordinate the conflict among high specific energy absorption SEA, high crush force efficiency CFE and good deformation modes of the energy absorbing structure, and the overall structure has good collision safety.

Description

technical field [0001] The invention relates to the field of automobiles, in particular to a multicellular thin-walled energy-absorbing structure. In the design of front side members and crash boxes of automobiles Background technique [0002] The design of the energy-absorbing structure of the front cabin of a car is of great significance to the safety of car crashes. During a frontal collision of a car, the collision energy absorbed by the front side beam and the crash box accounts for more than half of the collision energy of the vehicle, and the deformation modes and energy absorption characteristics of these two energy-absorbing structures have a great influence on the transmission path of the collision force during the collision And acceleration response has a decisive influence, therefore, under the trend that automobile collision safety and body weight are constantly being emphasized, the design of such energy-absorbing structures has become a key research technolog...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B60R19/02B60R19/03B62D21/15

CPCB60R19/02B60R19/03B62D21/15

Inventor 曹洋陈涛周亚妮段利斌聂昕

Owner HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com