Nitraria branch and leaf extract

A technology of extract and Nitraria, applied in the direction of drug combination, plant raw materials, plant/algae/fungus/moss components, etc., can solve the problems of low efficiency, high extraction cost, incomplete recovery of organic solvents, etc., and achieve simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

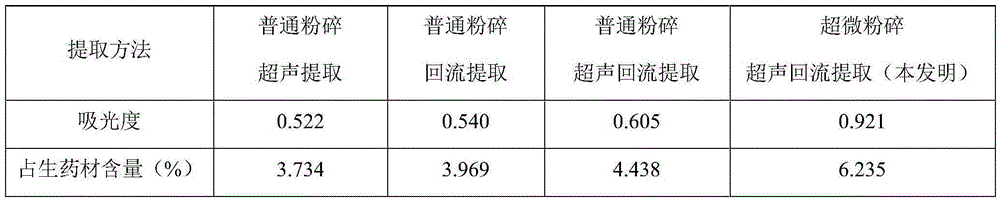

Image

Examples

Embodiment 1

[0040] 1. Cleaning: select 10kg of mature Nitraria branches and leaves, sieve out the sediment, and wash with water;

[0041] 2. Drying: Dry the cleaned Nitraria branches and leaves at 15°C for 15 hours at low temperature;

[0042] 3, crushing: the Nitraria branches and leaves obtained in step 2 are ultrafinely pulverized to obtain Nitraria branches and leaves powder;

[0043] 4. Extraction: Add 5 times the amount of 70% ethanol to the Nitraria branch and leaf powder obtained in step 3 for ultrasonic extraction for 1 hour, stir with a stirrer during this period, obtain filtrate I and filter residue I after filtration, and use filter residue I again for 7 times A large amount of 70% ethanol was refluxed and extracted for 1 h, and the filtrate II and filter residue II were obtained after filtration, the filtrate I and the filtrate II were combined, and concentrated under reduced pressure to obtain the crude extraction part of the total flavonoids of the branches and leaves of Ni...

Embodiment 2

[0047] 1. Cleaning: select 10kg of mature Nitraria branches and leaves, sieve out the sediment, and wash with water;

[0048] 2. Drying: Dry the cleaned Nitraria branches and leaves at 20°C for 15 hours at low temperature;

[0049] 3, crushing: the Nitraria branches and leaves obtained in step 2 are ultrafinely pulverized to obtain Nitraria branches and leaves powder;

[0050]4. Extraction: Add 8 times the amount of 70% ethanol to the powder of Nitraria thorn leaves obtained in step 3 for ultrasonic extraction for 1 hour, stir with a stirrer during this period, obtain filtrate I and filter residue I after filtration, and use filter residue I again for 6 times A large amount of 80% ethanol was refluxed and extracted for 1 h, and the filtrate II and filter residue II were obtained after filtration, the filtrate I and the filtrate II were combined, and concentrated under reduced pressure to obtain the crude extraction part of the total flavonoids of the branches and leaves of Nit...

Embodiment 3

[0054] 1. Cleaning: select 10kg of mature Nitraria branches and leaves, sieve out the sediment, and wash with water;

[0055] 2. Drying: Dry the cleaned Nitraria branches and leaves at 15°C for 20 hours at low temperature;

[0056] 3, crushing: the Nitraria branches and leaves obtained in step 2 are ultrafinely pulverized to obtain Nitraria branches and leaves powder;

[0057] 4. Extraction: Add 5 times the amount of 70% ethanol to the Nitraria branch and leaf powder obtained in step 3 for ultrasonic extraction for 1.5 hours, stir with a stirrer during this period, obtain filtrate I and filter residue I after filtration, and use filter residue I again for 7 Doubling the amount of 65% ethanol for reflux extraction for 1.5 h, after filtration, filtrate II and filter residue II were obtained, the filtrate I and filtrate II were combined, concentrated under reduced pressure to obtain the crude extraction part of the total flavonoids of the branches and leaves of Nitraria japonica;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com