Cooling box

A technology for cooling boxes and boxes, which can be applied to coolers, refrigerated rooms, household refrigeration devices, etc., can solve the problems of high labor intensity for workers, and achieve the effect of reducing labor intensity and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

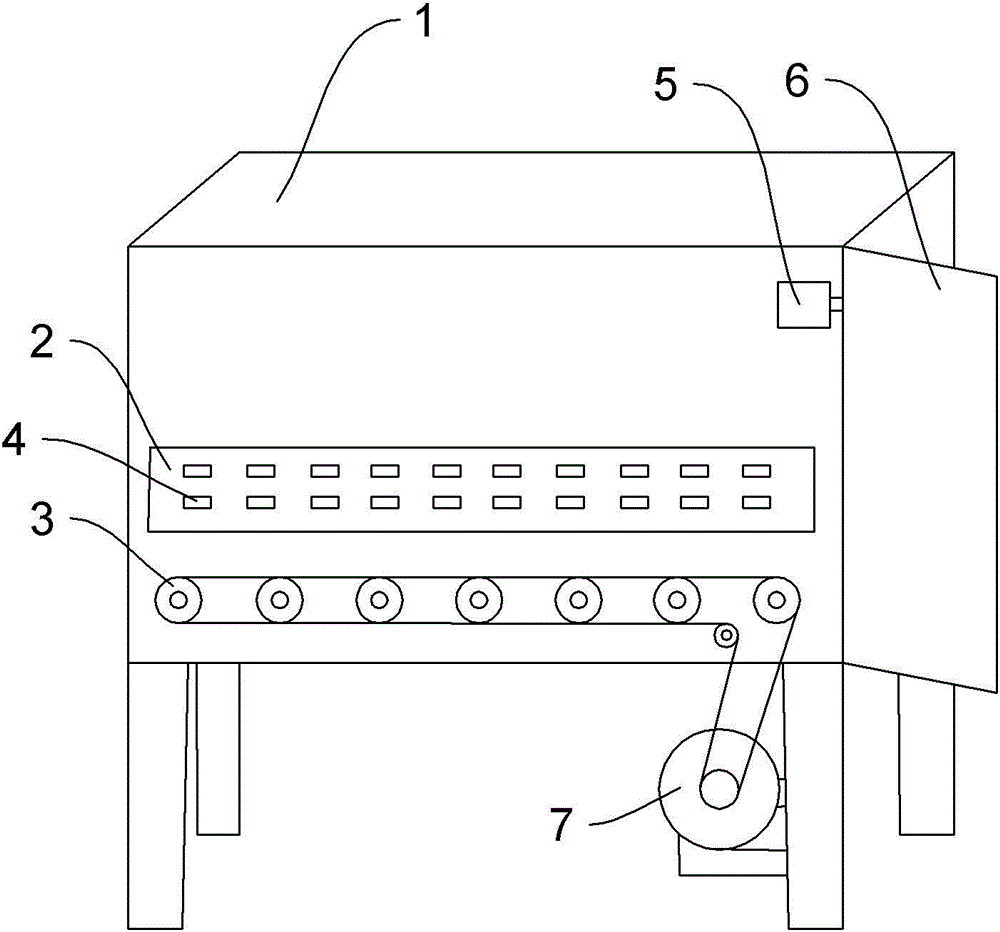

[0015] In the figure: box body 1, limit plate 2, supporting roller 3, roller 4, limit switch 5, discharge door 6, motor 7.

[0016] like figure 1 The cooling box shown includes a bracket, on which a motor 7 is arranged, and a box body 1 is arranged above the motor 7, and the box body 1 is welded to the upper end of the bracket. The left side of the box body 1 is provided with a material inlet and a material inlet door, and the right side is provided with a material outlet and a material outlet door 6 . Both the feed door and the discharge door 6 are provided with a limit switch 5, and the limit switch 5 is electrically connected with the motor 7. When the feed door or the discharge door 6 is opened to 90 o , the limit switch 5 will be triggered, thereby starting the motor 7 to rotate. The bottom of the box body 1 is provided with some ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com