Automatic split guard bar device for highway contingency runway

A technology for combat readiness runways and highways, which is applied to road safety devices, roads, roads, etc., can solve problems such as insufficient stability, increased preparation time for expressway combat readiness runways, and hidden safety hazards, so as to achieve reasonable structure, reduce preparation time, and eliminate The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

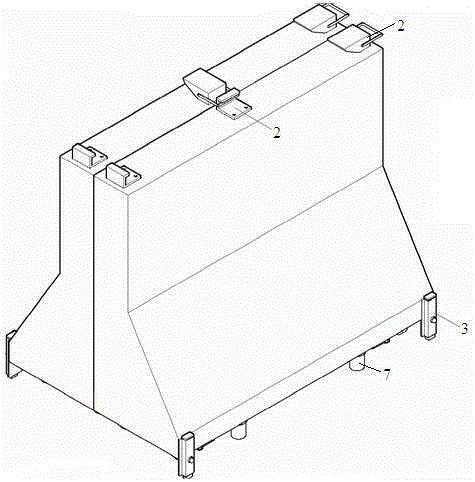

[0014] The specific content of the present invention will be described in detail in conjunction with the accompanying drawings. An automatic splitting guardrail device for a highway combat readiness runway, which is formed by connecting multiple sections of guardrails 1 sequentially through buckles 2, each section of guardrail 1 is fixed in the middle of the highway combat readiness runway 4 through a limit latch 3, and the guardrail 1 is composed of The two split guardrails 5 are connected by a buckle 2 after they are docked. The two sides of the bottom of the split guardrail 5 are respectively provided with electric casters 6 for balancing and moving the split guardrail 5, and the bottom of the split guardrail 5 is equipped with The hydraulic push rod 7 that drives the split guardrail 5 to tilt in the opposite direction, the opposite side of the split guardrail 5 is respectively equipped with an electric strut mechanism, an active caster mechanism and a groove 8, and the acti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap