Electroplating equipment discharge control system and its control method

An electroplating equipment and control system technology, applied in the direction of circuits, electrolytic processes, electrolytic components, etc., can solve the problems of high manual operation intensity, low automation, and large human errors, and achieve accurate and orderly transmission, high automation, and responsiveness fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

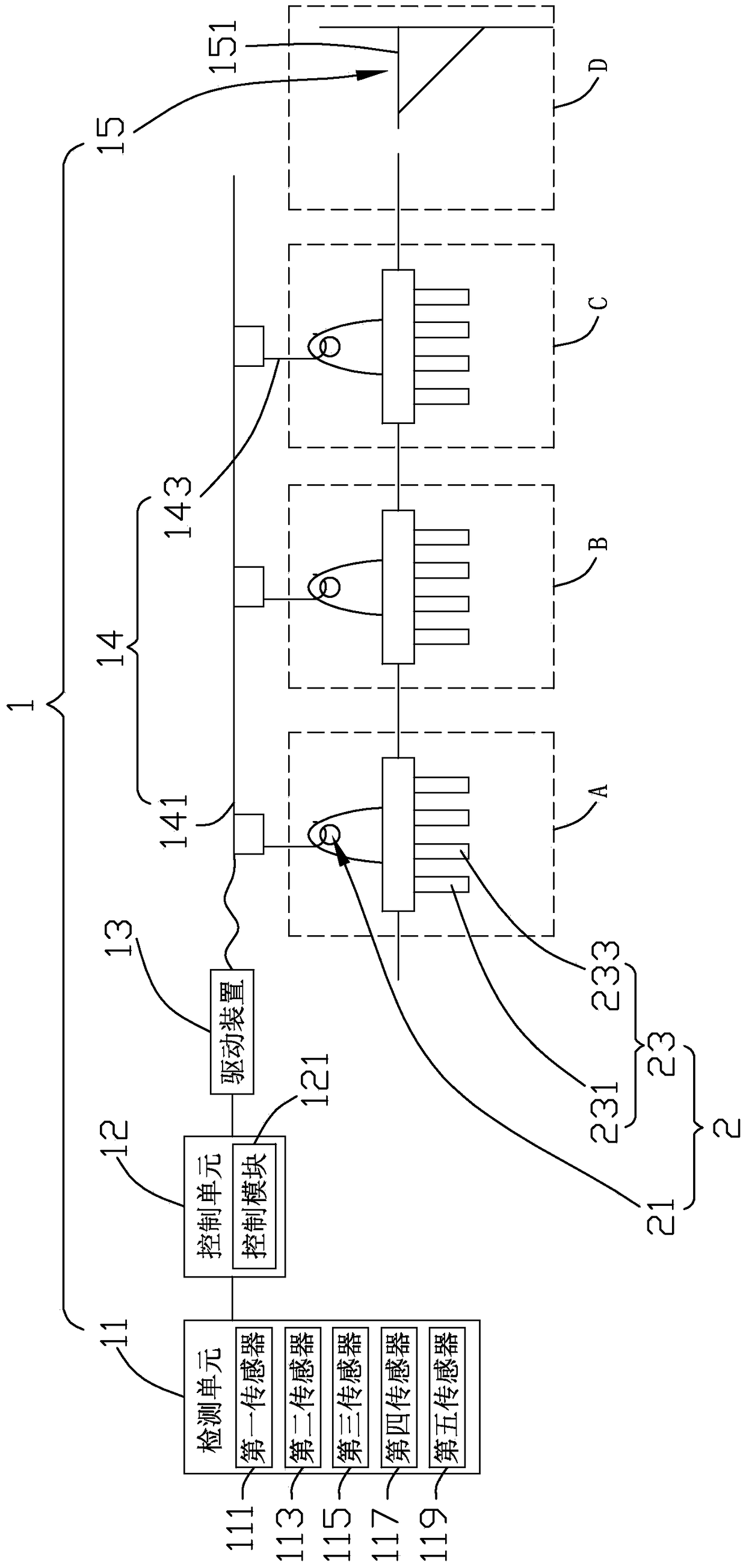

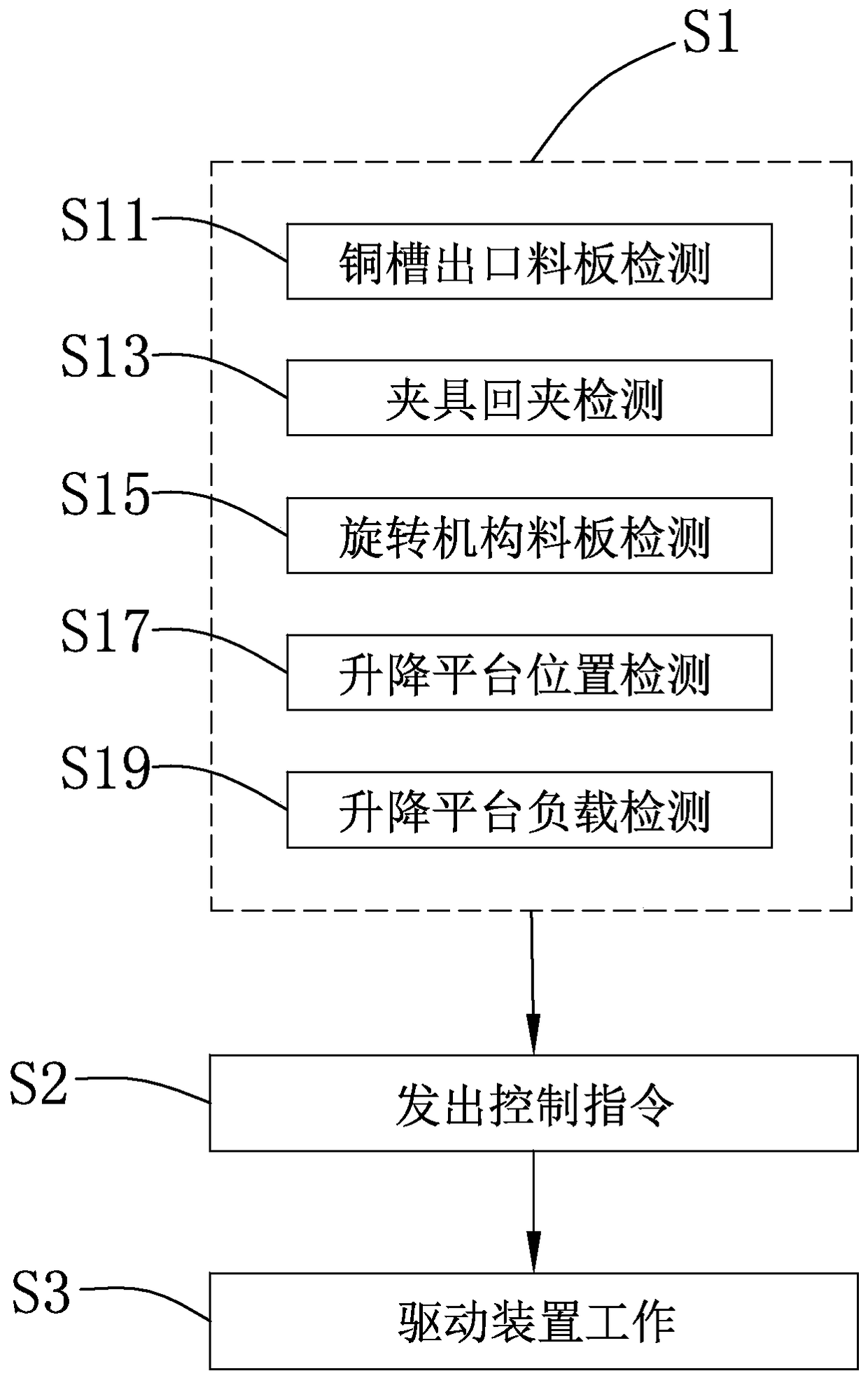

[0028] see figure 1 , is a structural schematic diagram of the discharge control system of the electroplating equipment of the present invention. During the discharge process, under the control of the discharge control system 1 of the electroplating equipment, the hanger 2 sequentially passes through the copper tank discharge station A, the automatic unloading station B, and the hanger clamping station along the discharge transmission direction. C and platform lifting station D. The hanger 2 is supported on a guide rail (not numbered) arranged along the direction of the discharging conveyance.

[0029] The discharge control system 1 of the electroplating equipment includes a detection unit 11 , a control unit 12 , a driving device 13 , a traction device 14 , a guide rail (not labeled), a rotating mechanism (not shown) and a lifting device 15 . The si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com