Low-hydrocarbon fracturing fluid cross-linking agent and preparation method thereof

A technology of fracturing fluid and low-carbon hydrocarbons, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., which can solve the problems of unsatisfactory requirements, poor temperature resistance of fracturing fluid, and uncontrollable crosslinking time of fracturing fluid and other problems, to achieve the effect of controllable cross-linking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

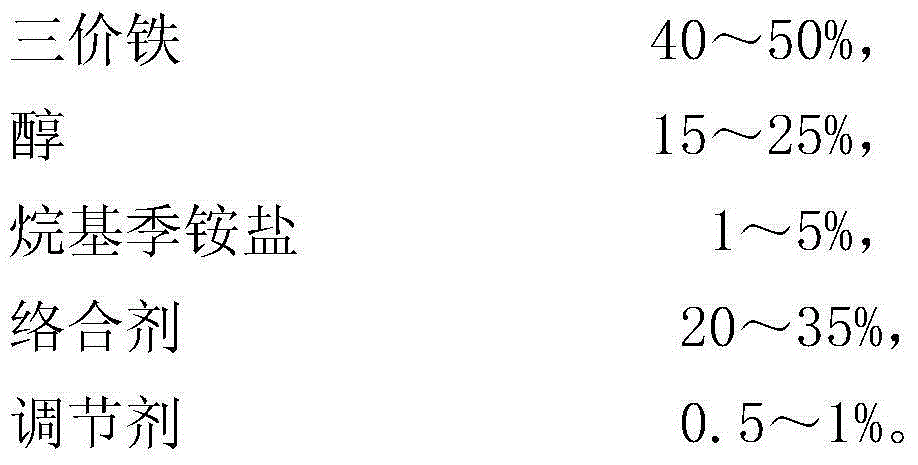

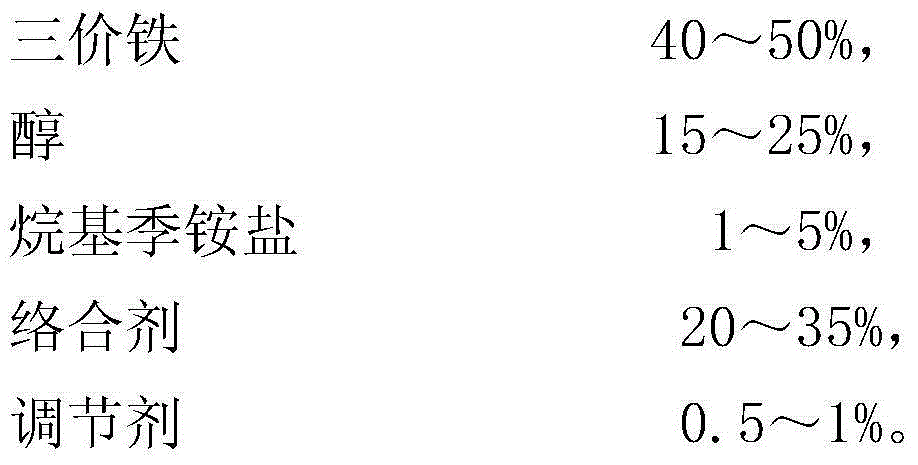

[0022] Based on the total mass of raw materials participating in the polymerization, the crosslinking agent is synthesized according to the following specific steps:

[0023] 1) Preparation of crosslinking agent: 45g of ferric sulfate, 23g of ethylene glycol, 5g of dioctadecyldimethylammonium chloride, 23g of nitrilotriacetic acid, and 4g of sodium acetate were placed in a three-necked bottle.

[0024] 2) Adjust the temperature of the water bath to 55 degrees Celsius, turn on the stirrer, and set the stirring speed to 200 r / min.

[0025] 3) Reaction: The reaction was stopped for 6.5 hours under the condition of nitrogen (that is, nitrogen with a purity of 99.99%).

[0026] Take 0.5% of the reaction cross-linking agent and dialkyl phosphate with an addition of 0.5%, and add it into the propane liquid to cross-link to obtain a cross-linked gel. The cross-linking time is 60s. After cross-linking, the gel has good elasticity and can hang up. A MARS rheometer was used to test the...

Embodiment 2

[0028] Based on the total mass of raw materials participating in the polymerization, the crosslinking agent is synthesized according to the following specific steps:

[0029] 1) Preparation of crosslinking agent: 46g of ferric nitrate, 23g of glycerol, 5g of dibehenyldimethylammonium chloride, 23g of EDTA, and 3g of sodium acetate were placed in a three-necked bottle.

[0030] 2) Adjust the temperature of the water bath to 55 degrees Celsius, turn on the stirrer, and stir at a speed of 200 r / min.

[0031] 3) Reaction: The reaction was stopped for 6.5 hours under the condition of nitrogen (that is, nitrogen with a purity of 99.99%).

[0032] Take 0.45% of reactive cross-linking agent and 0.5% of dialkyl phosphate, add it into butane liquid to cross-link to obtain cross-linked jelly, cross-linking time is 180s, after cross-linking, the jelly has better elasticity Adjustable hanging. A MARS rheometer was used to test the temperature and shear resistance of the jelly. The resul...

Embodiment 3

[0034] Based on the total mass of raw materials participating in the polymerization, the crosslinking agent is synthesized according to the following specific steps:

[0035] 1) Preparation of cross-linking agent: 42g of ferric chloride, 20g of glycerol, 5g of uncodecyltrimethylammonium chloride, 30g of HEDP, and 3g of sodium acetate were placed in a three-necked bottle.

[0036] 2) Adjust the temperature of the water bath to 60 degrees Celsius, turn on the stirrer, and the stirring speed is 200 r / min.

[0037] 3) Reaction: The reaction was stopped for 6.5 hours under the condition of nitrogen (that is, nitrogen with a purity of 99.99%).

[0038] Take 0.45% of the reactive crosslinking agent and 0.5% of the dialkyl phosphate, and add it into the pentane liquid for crosslinking to obtain a crosslinked jelly. The crosslinking time is 90s. After crosslinking, the jelly has good elasticity. Adjustable hanging. A MARS rheometer was used to test the temperature and shear resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com