Self-cleaning waste conveying system for energy recovery

A technology for waste transportation and energy recovery, which is applied in the direction of conveyors, garbage cans, garbage collection, etc. It can solve the problems of high-rise buildings that cannot be applied, domestic waste is easy to pollute, technical requirements, and high installation requirements, so as to reduce management costs and save power. Consumption, the effect of reducing manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

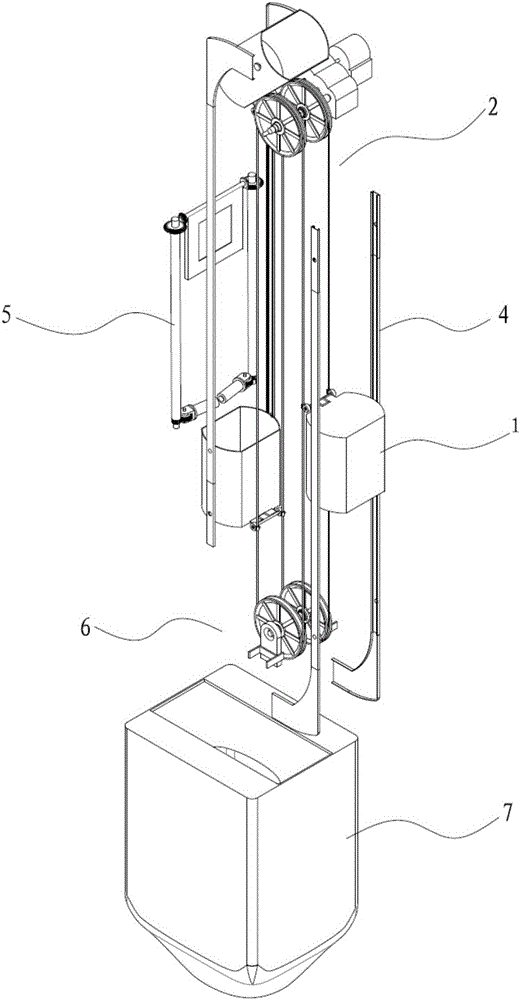

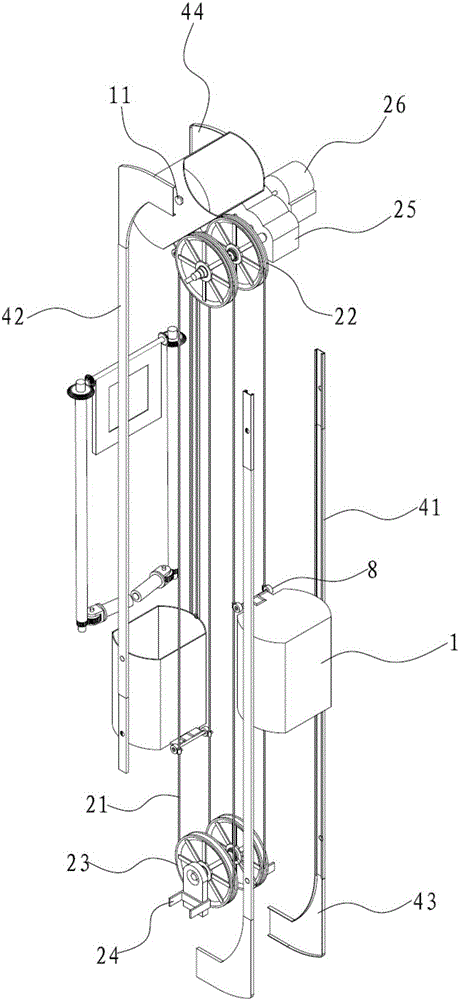

[0034] Such as figure 1 As shown, an energy recovery and self-cleaning garbage conveying system includes a lifting mechanism 2 for driving a garbage can 1, a limit rail 4, an instant stop mechanism 5 and a garbage storage box 7.

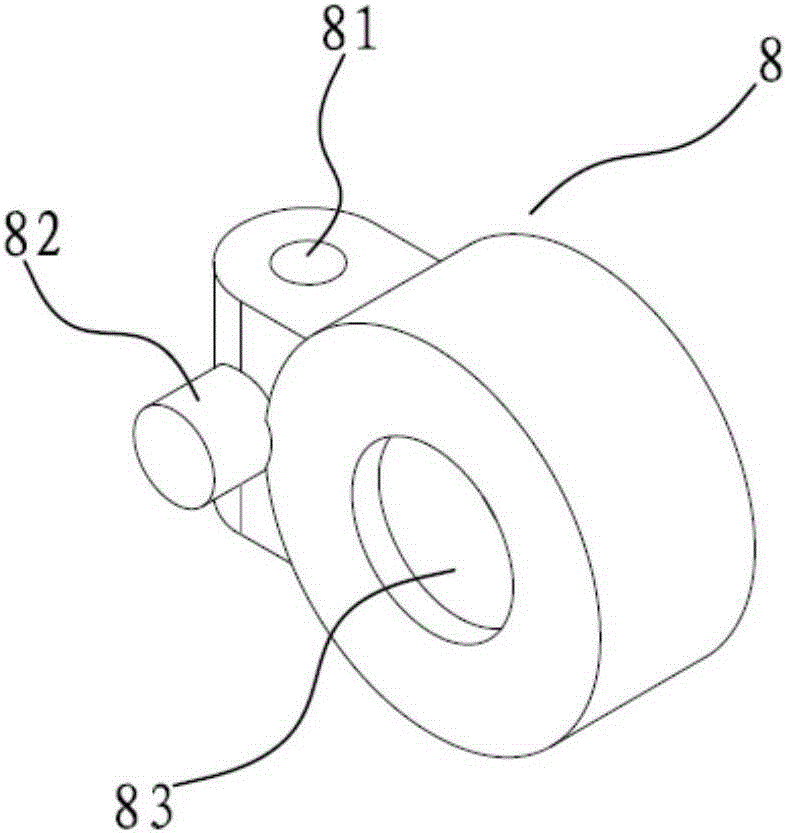

[0035] The lifting mechanism 2 is used to transport the garbage bin 1 in a cycle, including two fixed pulleys 22 and two fixed pulleys 23, which are coaxially arranged on the top and bottom of the building respectively, and the two fixed pulleys on the same vertical line form a group. Wire rope 21 is wound on the set pulley, and garbage bin 1 is fixed on the wire rope 21 by connecting seat 8 at intervals, and the distance between garbage bin 1 is fixed as the floor height, and wire rope 21 straddles two fixed pulleys up and down to form a ring.

[0036] In this embodiment, each floor corresponds to two garbage cans 1, which are respectively arranged on both sides of the device. The garbage can 1 on one side is close to the garbage disposal port of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com