Grinding and riveting clamp

A clamp and rolling riveting technology, applied in the field of rolling riveting, can solve the problems of manual fixation, difficult to take out the cushion, etc., and achieve the effect of reducing the risk, easy and quick assembly and disassembly, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

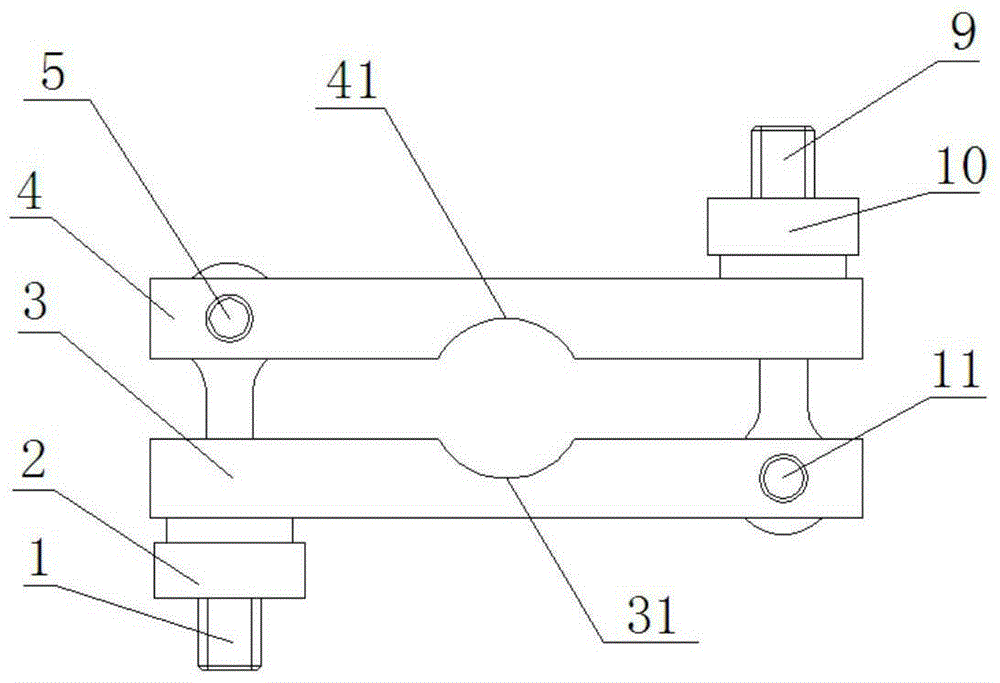

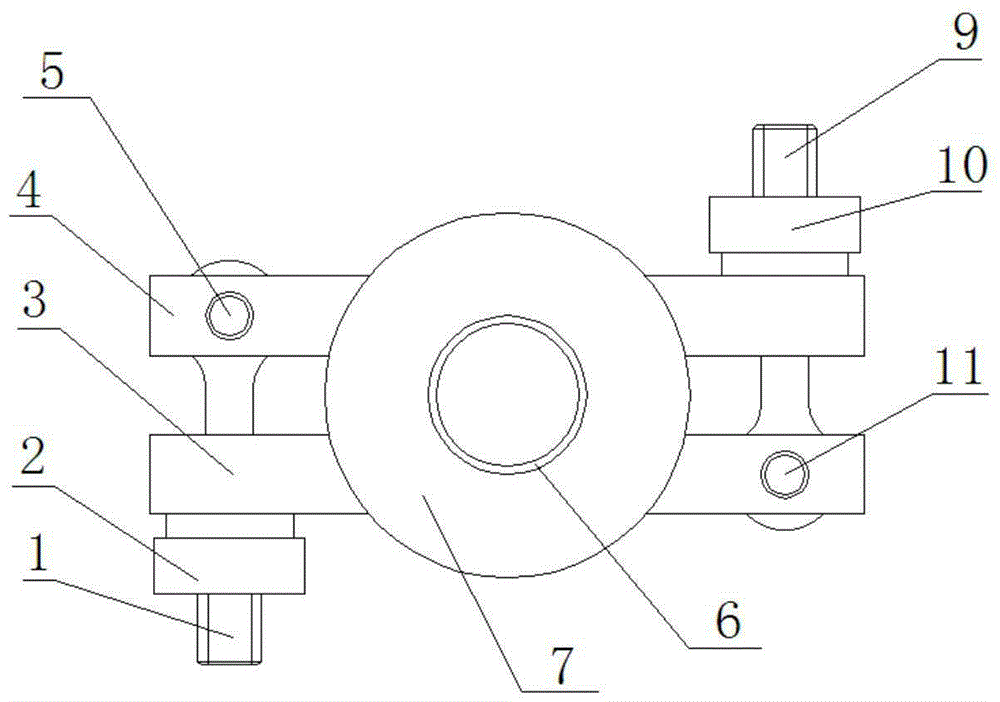

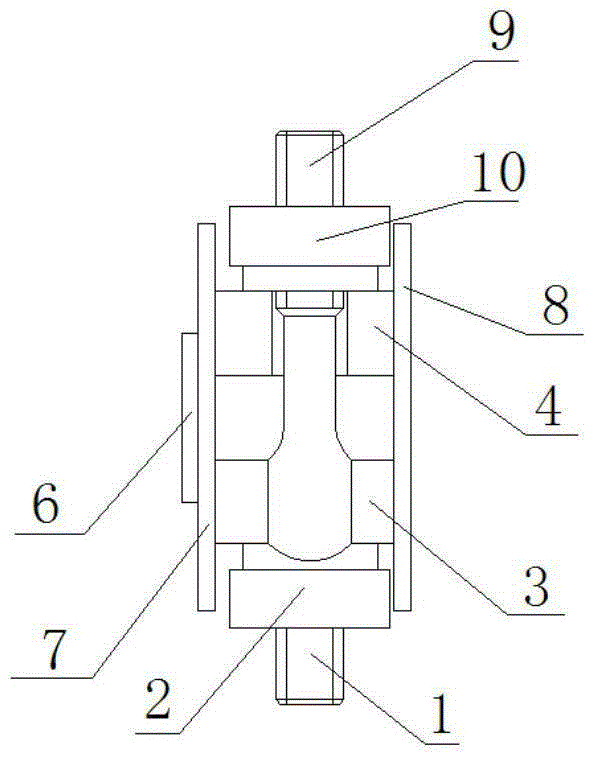

[0018] Such as Figure 1 to Figure 4 A rolling riveting jig shown includes movable bolt A1, lock nut A2, pad M3, pad N4, pin B5, movable bolt B9, lock nut B10 and pin A11; said pad M3 and pad N4 is respectively provided with a card slot M31 and a card slot N41, and the card slot M31 is opposite to the card slot N41; the left end of the spacer M3 and the spacer N4 are connected by a movable bolt A1, and one end of the movable bolt A1 is connected by a pin B5 It is movable installed on the pad N4, and the other end is placed in the slot at the left end of the pad M3, and the end is also covered with a lock nut A2; the right end of the pad M3 and the pad N4 are connected by a movable bolt B9, One end of the movable bolt B9 is movably mounted on the pad M3 through the pin A11, and the other end is placed in the slot at the right end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com