Industrial high-speed centrifugal machine

A high-speed centrifuge, industrial technology, applied in the field of centrifuges, can solve the problems of loss of sealing effect, wear of inner baffle plate, cumbersome disassembly and assembly process, etc., and achieve the effect of improving performance, saving maintenance cost and reducing maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

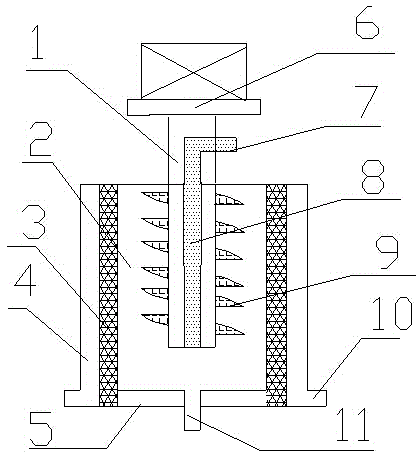

[0012] like figure 1 As shown, a kind of industrial high-speed centrifuge comprises centrifugal bin 2, feed pipe 8, discharge opening 10, and described centrifugal bin 2 is cylindrical vertical structure, is provided with the rotating shaft 1 driven by motor 6 on it, The two ends of the rotating shaft 1 protrude from the centrifugal bin 2, and the hollow structure inside the rotating shaft 1 is provided with a feeding pipe 8, and one end of the feeding pipe 8 is connected to the feeding port 7, and on the rotating shaft 1 An impeller 9 is provided, the feed pipe 8 is connected to the interior of the rotating shaft 1, a filter layer 3 for filtering the centrifuged material is provided on both sides of the centrifugal chamber 2, and a material blocking plate 5 is provided at the lower end of the centrifugal chamber 2 A slag outlet 11 is provided in the middle of the baffle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com