Red bean paste processing technology

A processing technology and technology of red bean paste, applied in the fields of application, food preparation, food science, etc., can solve the problems of restricting the economic benefit of industrial production of red bean paste, affecting the water absorption rate of red bean paste, and large hardness of red bean paste, and shortening the cooking time. The effect of reducing the cooking time, the bean skin is obvious, and the cooking time is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The processing method of red bean paste in this embodiment, the specific operation steps are:

[0026] (1) Raw material processing:

[0027] 1) Picking: picking the red adzuki beans to be processed, picking out impurities such as stones, clods, bad beans, miscellaneous beans, moldy beans, and retaining the full-grained adzuki beans as the raw material red adzuki beans;

[0028] 2) Rinse: Pour the raw adzuki beans picked in step 1) into clean water and wash them 3 times;

[0029] 3) Drying: Spread the rinsed raw adzuki beans evenly on the stainless steel workbench until there is no obvious moisture on the surface;

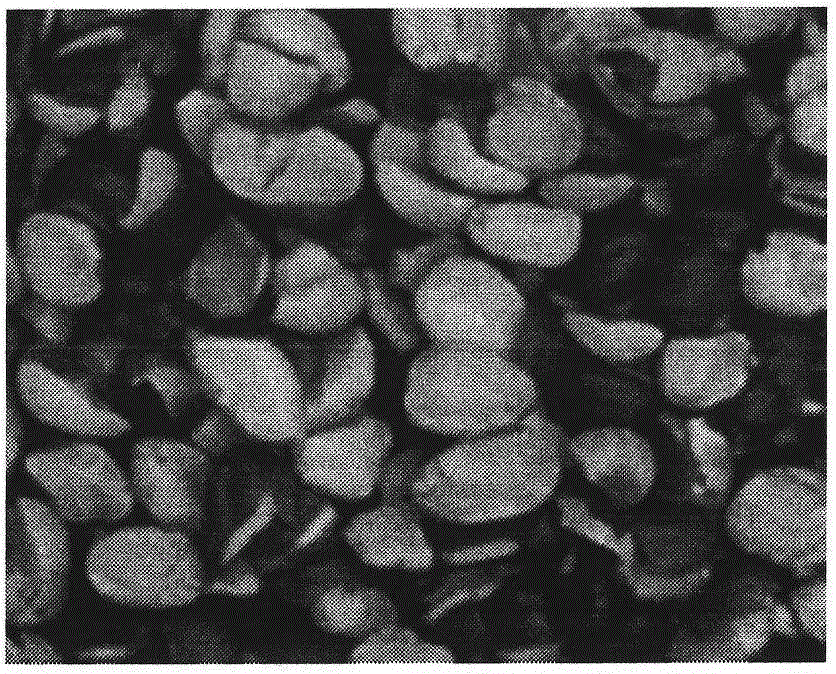

[0030] 4) Crushing treatment: the dried adzuki beans are crushed in a pulverizer, and the raw adzuki beans that are broken into 2 to 3 petals are screened out, such as figure 1 Shown

[0031] (2) Cooking: take the crushed and sieved raw adzuki beans in step (1), add 6 times the amount of water, wait until the water is boiled, start timing, and cook for 25 minutes;

[003...

Embodiment 2

[0034] The processing method of red bean paste in this embodiment, the specific operation steps are:

[0035] (1) Raw material processing:

[0036] 1) Picking: picking the adzuki beans to be processed, picking out impurities such as stones, clods, bad beans, miscellaneous beans, moldy beans, and retaining the full-grained adzuki beans as the raw material red adzuki beans;

[0037] 2) Rinsing: Pour the raw adzuki beans picked in step 1) into clean water and wash them twice;

[0038] 3) Drying: Spread the rinsed raw adzuki beans evenly on the stainless steel workbench until there is no obvious moisture on the surface;

[0039] 4) Crushing treatment: the dried adzuki beans are crushed in a pulverizer, and the raw adzuki beans that are broken into 2 to 3 petals are screened out;

[0040] (2) Cooking: take the crushed and sieved raw adzuki beans in step (1), add 4 times the amount of water, and start timing after the water is boiled, and cook for 20 minutes;

[0041] (3) Stir-frying: 90 parts ...

Embodiment 3

[0043] The processing method of red bean paste in this embodiment, the specific operation steps are:

[0044] (1) Raw material processing:

[0045] 1) Picking: picking the red adzuki beans to be processed, picking out impurities such as stones, clods, bad beans, miscellaneous beans, moldy beans, and retaining the full-grained adzuki beans as the raw material red adzuki beans;

[0046] 2) Rinse: Pour the raw adzuki beans picked in step 1) into clean water and wash them 5 times;

[0047] 3) Drying: Spread the rinsed raw adzuki beans evenly on the stainless steel workbench until there is no obvious moisture on the surface;

[0048] 4) Crushing treatment: the dried adzuki beans are crushed in a pulverizer, and the raw adzuki beans that are broken into 2 to 3 petals are screened out;

[0049] (2) Cooking: Take the crushed and sieved raw adzuki beans in step (1), add 10 times the amount of water, and start timing after the water is boiled, and cook for 30 minutes;

[0050] (3) Stir-frying: 120 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com