Motor and rotor thereof

A technology of motor rotor and rotor winding, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as affecting the efficiency of the motor and shortening the service life of the motor, and achieve the effect of improving heat dissipation and improving heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

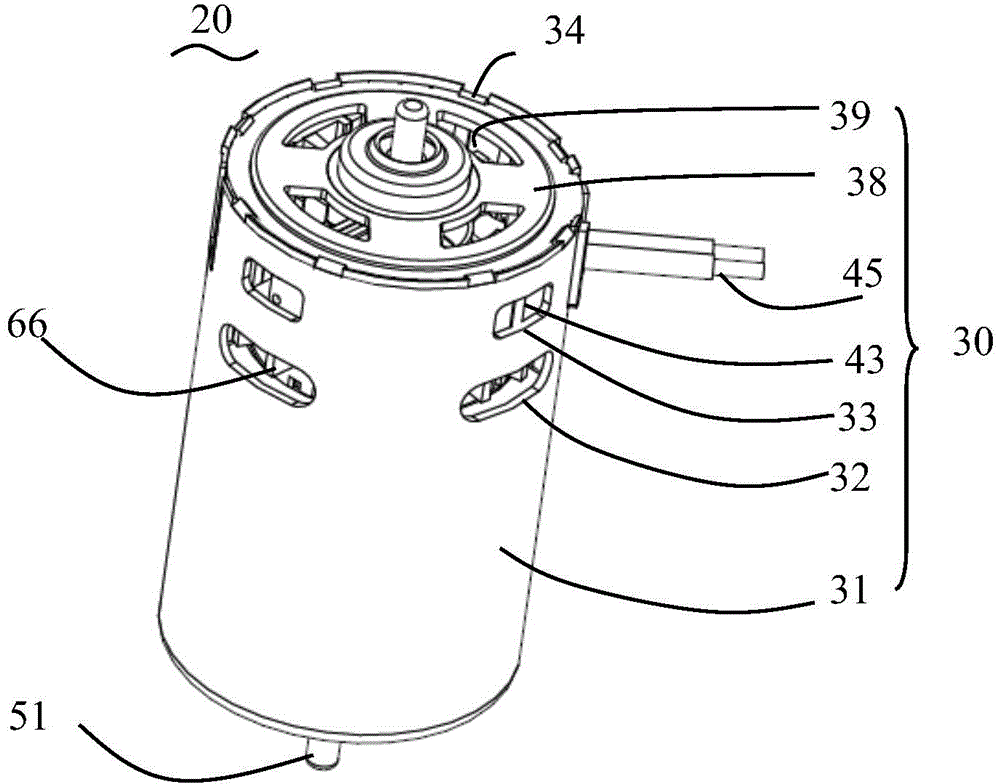

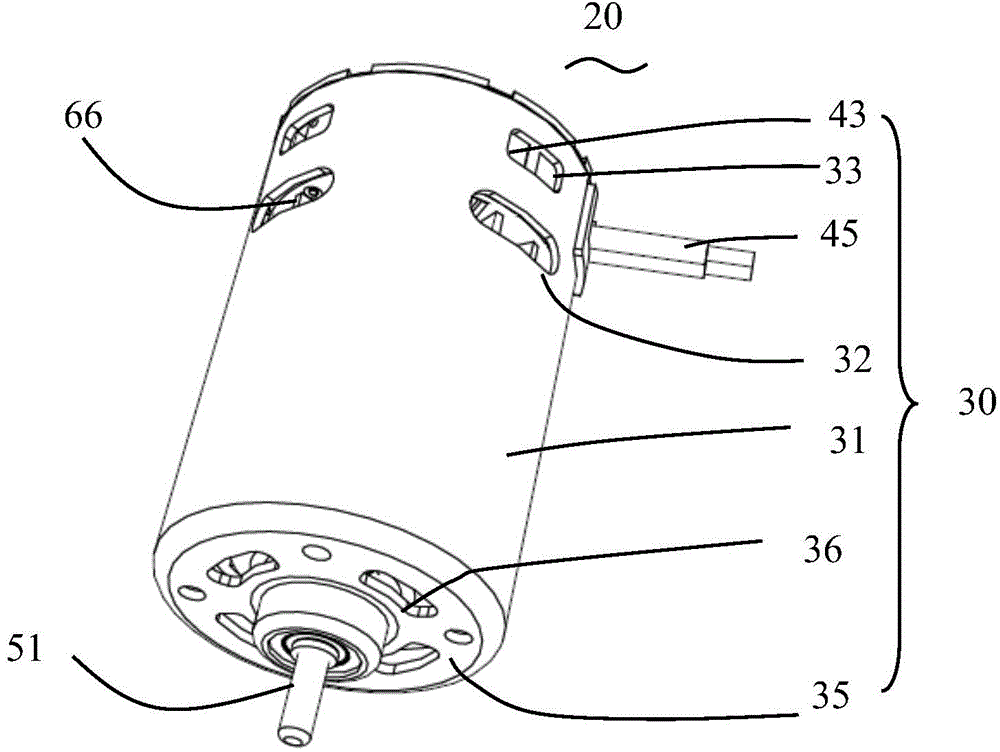

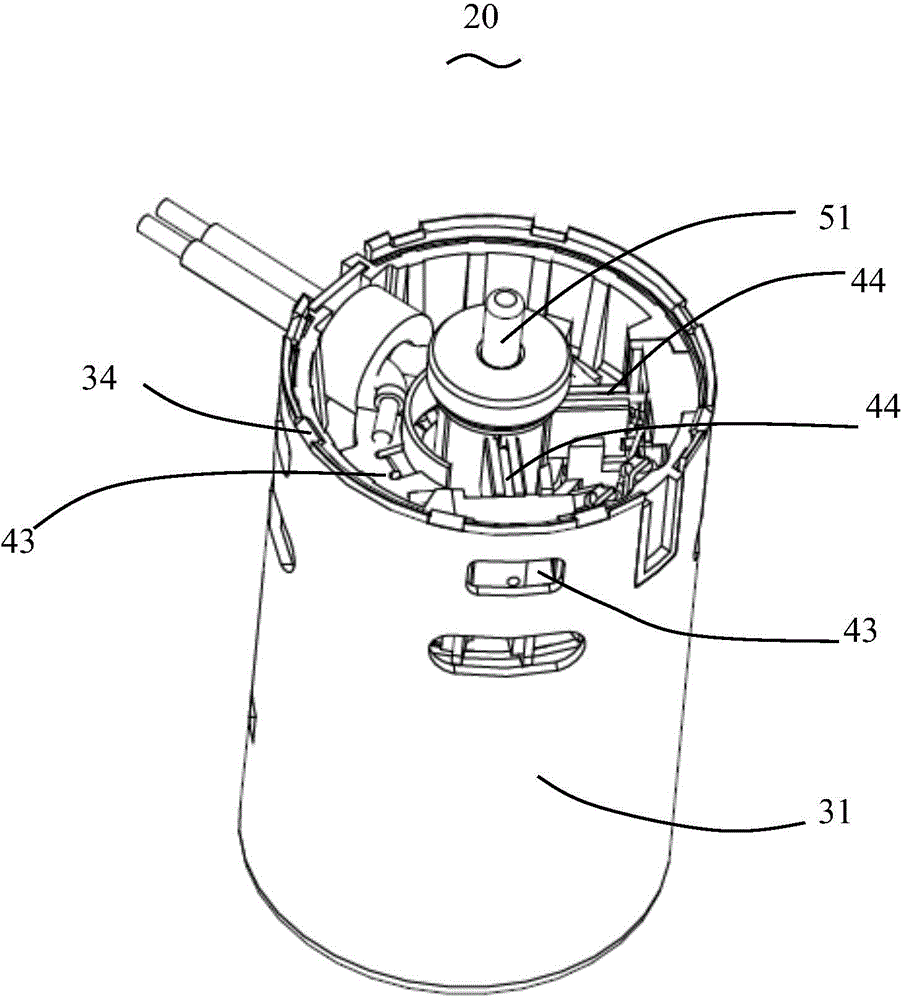

[0027] refer to Figure 1 to Figure 9 , The motor 20 provided by one embodiment of the present invention is a permanent magnet direct current (PMDC) brushed motor. The motor 20 includes a stator 30 and a rotor 50 .

[0028] The stator 30 includes a cylindrical casing 31 with one end open, four permanent magnets 41 mounted to the inner wall of the casing 31 , a brush holder 43 mounted to one open end of the casing 31 , and an end cover 38 mounted to the open end. The open end of the shell 31 has a plurality of connecting pieces 34 , and after the end cover 38 is installed, the connecting pieces 34 are bent inward to fix the end cover 38 and the shell 31 together. The other end of the casing 31 is provided with a bottom 35 , and the bottom 35 and the end cover 38 are provided with bearing seats for mounting bearings 47 and 48 respectively. At least one pair of brushes 44 is mounted on the brush holder 43 , and the at least one pair of brushes 44 are respectively connected to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com