Active clearance control method and system

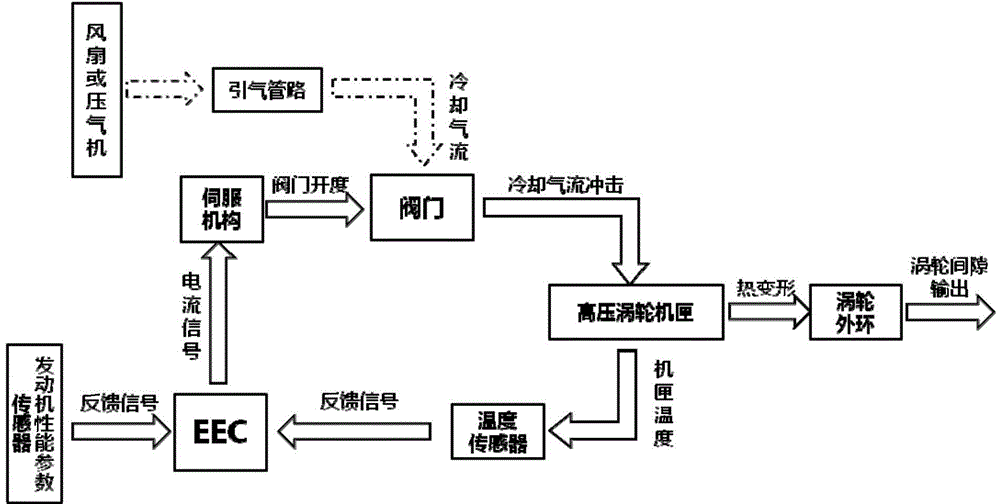

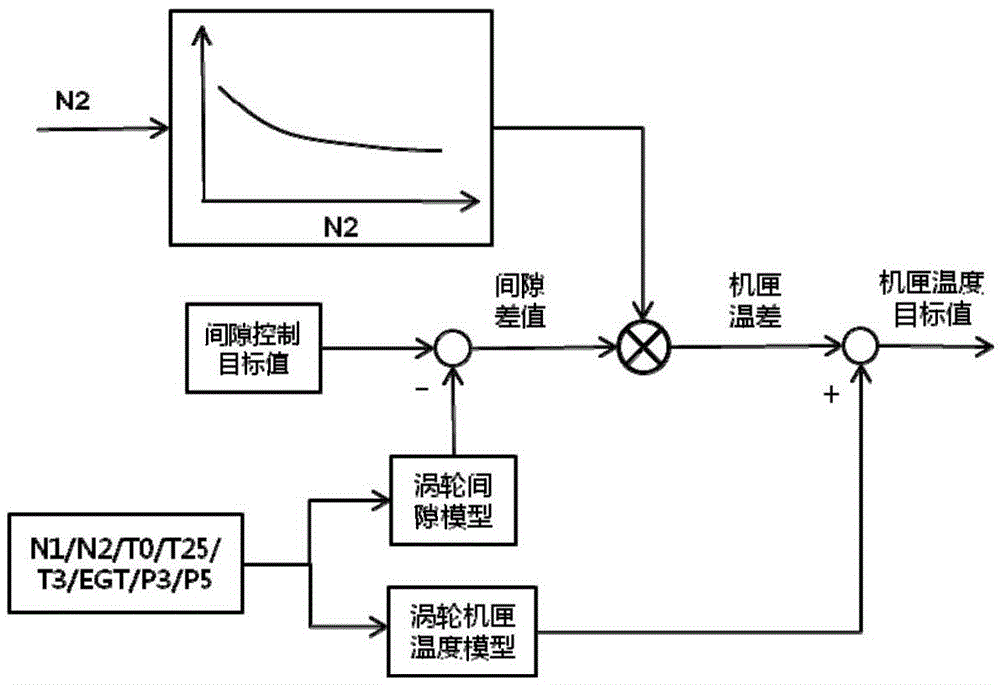

A control method and technology for a control system, which are applied in the field of active clearance control methods and systems, can solve the problems of difficulty in obtaining a temperature control plan of a turbine casing, poor clearance control accuracy, frequent actuation of a bleed valve, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0096] like figure 1 As shown, it is a schematic flowchart of the first embodiment of the active gap control method of the present invention. In this embodiment, the active gap control method includes:

[0097] Step 100, judging the current state of the aeroengine, if the aeroengine is in a steady state, then execute step 200, if the aeroengine is in a transition state, then execute step 300;

[0098] Step 200, selecting the closed-loop control process realized by the closed-loop controller to adjust the actuator affecting the turbine clearance based on clearance-related parameters;

[0099] Step 300, select an open-loop control process implemented by an open-loop controller to adjust the actuator based on the gap-related parameters.

[0100] The so-called turbine gap in this embodiment refers to the gap between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com