A gob-side entry retaining method and its filling method

A technology of flexible formwork and empty entry retaining, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of large lateral and longitudinal deformation, lateral or longitudinal rupture, and difficulty in pipeline installation, and achieves enhanced crack resistance, The effect of uniform force and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

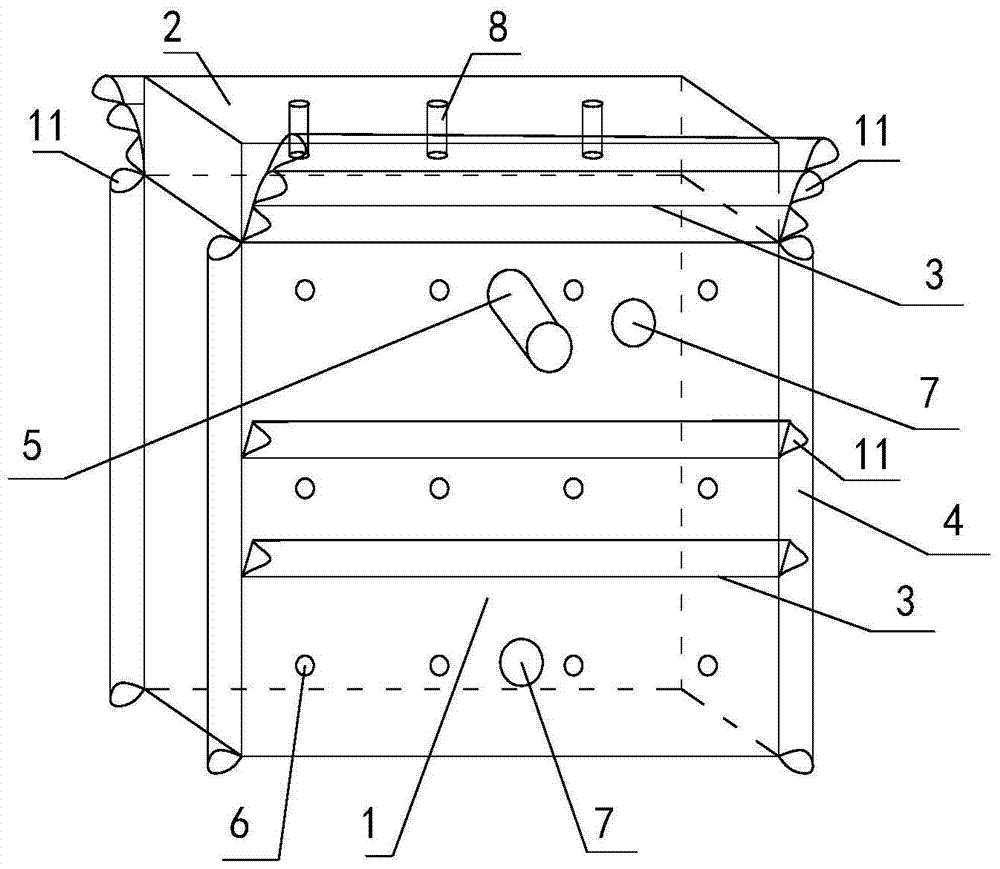

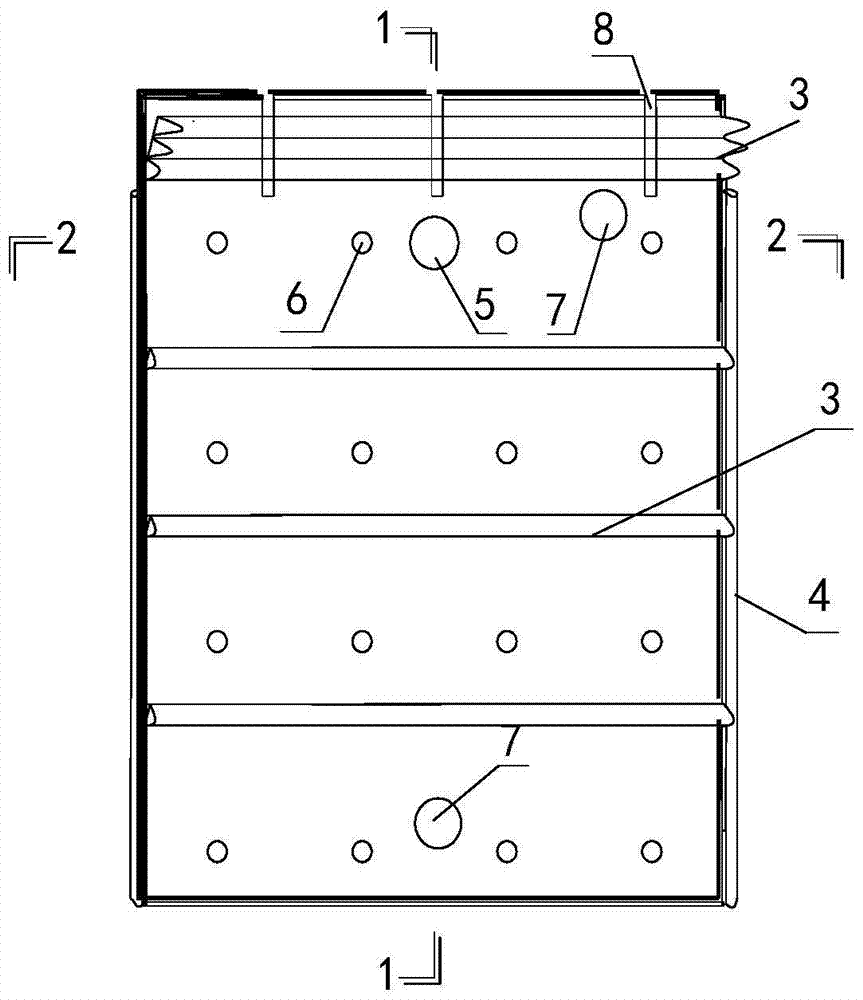

[0062] Embodiment 1, a filling method, using a gob-side entry retaining horizontally inclined double-stretched fiber flexible formwork, such as Figure 6 As shown, it is specifically implemented in the following ways and steps;

[0063] Step 1. According to the size of the position that needs to be filled between the roadway roof and the roadway floor in the gob-side entry retention, use wooden point columns 14 on the side of the goaf to block gangue support, and use single hydraulic props 15 on the side of the gob-side entry retention roadway Hanging nets to block gangue support;

[0064] Step 2. According to the length of filling, place several flexible formworks of gob-side entry retaining with double-stretched fibers;

[0065] Step 3. According to the size of the filling height, select the sleeve 11 on the top transverse flange 3 of the main body formwork 1, and penetrate the steel bars, and at the same time wear the steel bars on the transverse flange 3 in the middle of ...

Embodiment 2

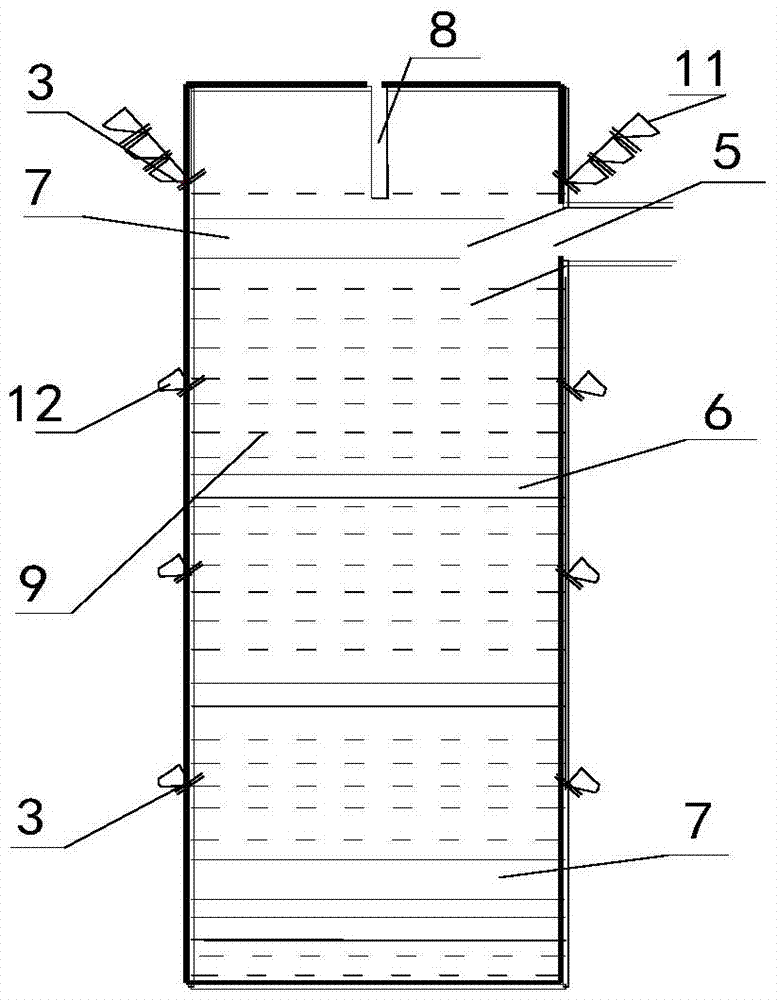

[0073] Embodiment 2, a filling method, using a gob-side entry retaining horizontally inclined double-stretched fiber flexible formwork, such as Figure 7 As shown, it is specifically implemented in the following ways and steps;

[0074] Step 1. According to the size of the position that needs to be filled between the roadway roof and the roadway floor in the gob-side entry retention, use the gangue-blocking hanging formwork support 13 on the side of the goaf to block gangue support, and use the single hydraulic pressure on the side of the gob-side entry retention roadway. Pillar 15 hangs the net and carries out gangue retaining support;

[0075] Step 2. According to the length of filling, place several flexible formworks of gob-side entry retaining with double-stretched fibers;

[0076] Step 3. According to the size of the filling height, select the sleeve 11 on the top transverse flange 3 of the main body formwork 1, and penetrate the steel bars, and at the same time wear th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com