High-strength and high-plasticity high manganese steel material and machining method thereof

A processing method and high manganese steel technology, applied in high manganese steel, high plasticity high manganese steel materials and their processing, high strength fields, can solve problems such as plasticity decline, achieve tensile strength and plasticity improvement, easy to achieve, The effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 5

[0031] The composition of the high manganese steel described in Example 1 is calculated by weight percentage: Mn34.5, C0.04%, S≤0.01%, P≤0.008%, and the rest is Fe and unavoidable impurities. The content of sulfur and phosphorus is restrictive. The specific processing steps are:

[0032] A. According to the above-mentioned component distribution ratio of high manganese steel, calculate the feeding ratio, melt the ingredients in a power frequency electric induction furnace, and smelt the ingredients into steel ingots in a positive argon pressure environment in the furnace to prevent Mn from volatilizing during the smelting process.

[0033] B. Post-treatment of steel ingots: keep the steel ingots in step A for heat treatment at 1150°C~1200°C for 2~4 hours, then transfer to room temperature, and homogeneously complete solution treatment in a water quenching pool; after solution treatment, The full dissolution of each phase in the ingot is conducive to improving the toughness an...

Embodiment 6~ Embodiment 9

[0051] Different from Example 1, the composition ratio of high manganese steel in step A is: Mn32, C0.04%, S≤0.01%, P≤0.008%, and the rest are different from Fe and unavoidable impurities; in step D, The annealing temperature is different, see Table 2 for details. According to the XRD test, they are all austenite structure.

[0052] Table 2 embodiment 6~10 test data

[0053]

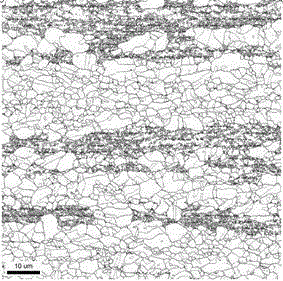

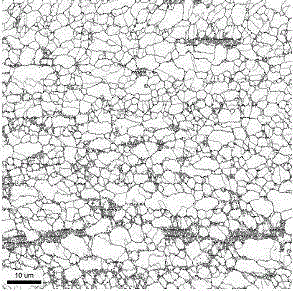

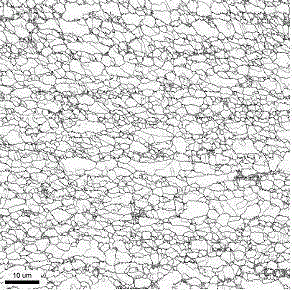

[0054] From Examples 6 to 10, it can be seen that partial recrystallization is used to obtain a mixed structure of coarse grains (grain size greater than about 5 microns) and ultrafine grains (size less than 1 micron), and the volume fraction of ultrafine grains is controlled at 20 ~30%, the plasticity of the strength of high manganese steel not only did not decrease but increased, which increased the strength and plasticity of high manganese steel.

Embodiment 11~14

[0056] A. According to the weight percentage of high manganese steel, it is Mn30%, C0.15%, S≤0.008%, P≤0.008%, Si≤0.01%, Cr7%, Ni0.25%, and the rest is Fe; calculate the feeding ratio and smelt into steel ingots; and electroslag remelting treatment.

[0057] B. Post-treatment of steel ingots: heat-treat the steel ingots in step A at 1150°C~1200°C for 2~4 hours, then transfer to room temperature, and homogenize in a water quenching pool to complete solution treatment.

[0058] C. Blanking and rolling into plates: the steel ingots treated in step B are heated to 900~1000°C, and then hot-rolled into rough sheets with a thickness of 10~20mm. The final rolling temperature is not lower than 900°C; Keep at ℃~1100℃ for 1~2 hours, then transfer to room temperature and water quenching tank for homogenization. Homogenization after hot rolling can eliminate stress concentration points caused by hot rolling.

[0059] Step D: the rough plate after hot rolling is cold-rolled at room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com